Continuous vertical feeding system and method for fluidized bed reactor

A fluidized bed reactor and feeding system technology, which is applied in the field of continuous vertical feeding system of fluidized bed reactors, can solve the problems of gas-solid reaction entrainment loss, adverse effects on subsequent production, easy-to-wear granular materials, etc., and achieves continuous automatic feeding , The effect of reducing the entrainment loss of gas-solid reaction and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

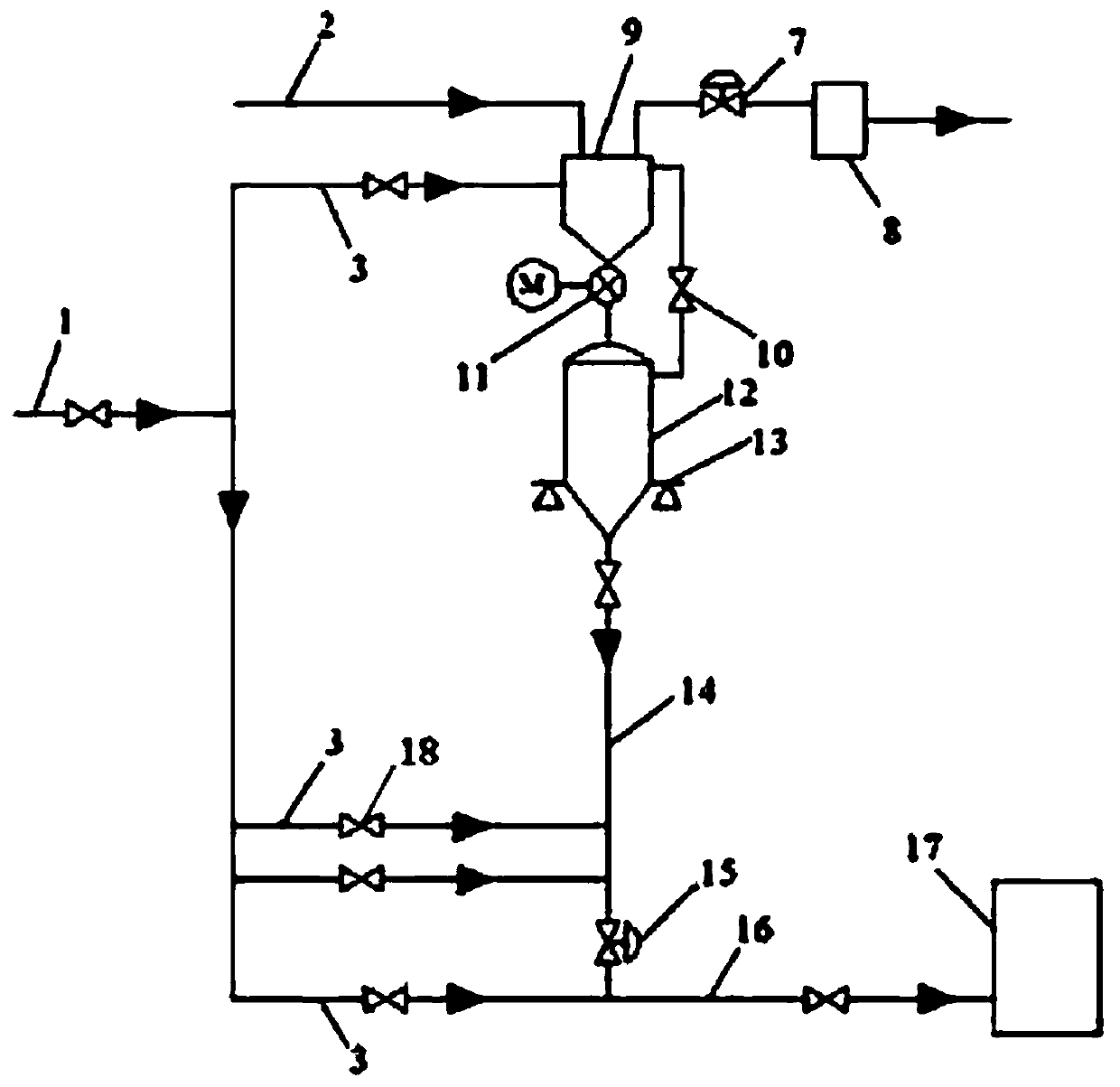

[0048] Such as figure 1 As shown, the granular material injection pipeline 2 is connected to the buffer bin 9, and the top of the buffer bin 9 is connected to the gas delivery branch pipe 3 and the exhaust self-regulating valve 7, so that the pressure of the feeding system can be controlled so that the pressure of the feeding system is greater than that of the fluidized bed reactor 17 pressure to prevent the granular material in the reactor from flowing back into the feeding system; the bottom of the buffer bin 9 is connected to the star feeder 11, and the lower part of the star feeder 11 is connected to the feed bin 12, between the buffer bin 9 and the feed bin 12 Connecting the pressure balance pipeline 10 can balance the pressure between the two feed bins and prevent the feeding pipe from being blocked. The feeding bin 12 is designed with a weighing module 13, which can weigh and calculate the feeding amount; the bottom of the feeding bin 12 is connected with the feeding ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com