Automatic feeding device for sheep breeding

An automatic and feed technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of low feed utilization rate, increase, and decrease of mutton output rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

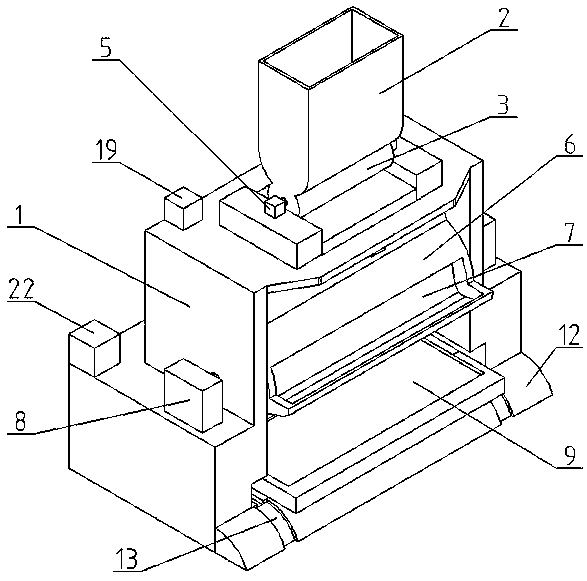

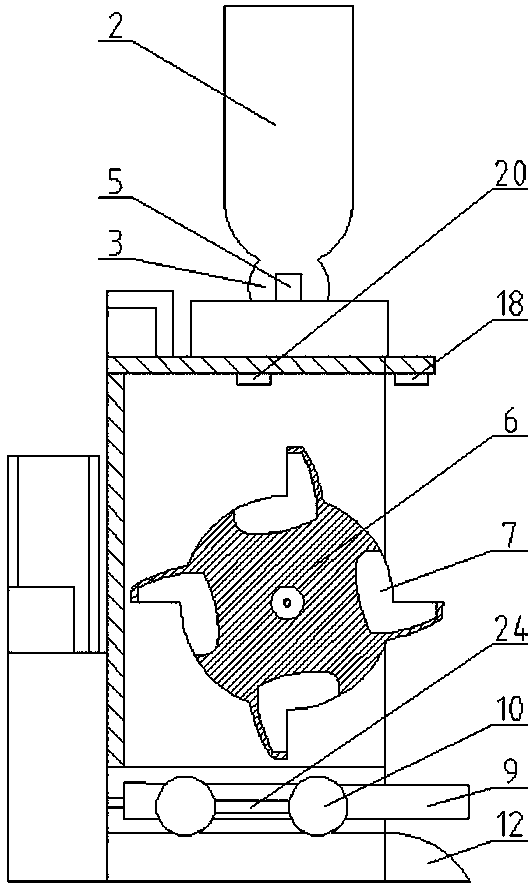

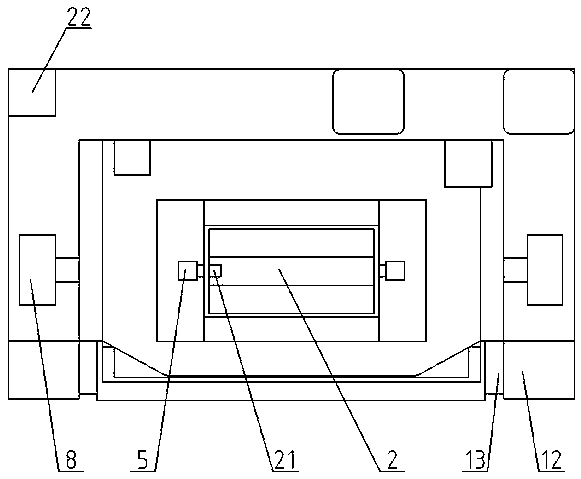

[0031] Referring to the accompanying drawings, the specific implementation is as follows:

[0032]An automatic feeding device for sheep breeding, comprising a housing 1, a feed box 2 is provided on the top of the housing 1, a discharge cavity 3 is provided at the bottom of the feed tank 2, and a feed box capable of sealing the feed box is provided in the discharge cavity 3 2 The fan-shaped body rotating shaft 4 of the bottom discharge port, the top of the housing 1 is also provided with a first motor 5 that can drive the fan-shaped body rotating shaft 4 to rotate; the fan-shaped body rotating shaft 4 is horizontally arranged, and the discharge port at the bottom of the feed box 2 is a A rectangular mouth arranged axially along the fan shaft 4; the sector angle of the fan shaft 4 is 90°, the discharge chamber 3 is a cylindrical structure, and the inner diameter of the discharge chamber 3 is the same as that of the fan shaft 4 The outer wall matches.

[0033] A feeding wheel 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com