Comprehensive detection device for parts in large amount

A technology for detecting devices and parts, applied in measuring devices, using optical devices, and optically testing flaws/defects, etc., can solve problems such as poor material discharge, small space, and lack of continuous batch processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0034] In the present invention, the detection object of the omni-directional detection method of this part is a small part with front and back sides and requires quality inspection, such as rubber sealing ring, plastic bearing, plastic gear, nut, gear, bearing, bush, sheet Parts, magnetic blocks, magnetic tiles, etc.

[0035] In the present invention, the conveyor belt refers to one of belt conveyors, metal plate chain conveyors, and plastic plate chain conveyors, preferably a belt conveyor. The conveying surface refers to the working surface of the conveyor belt for conveying samples.

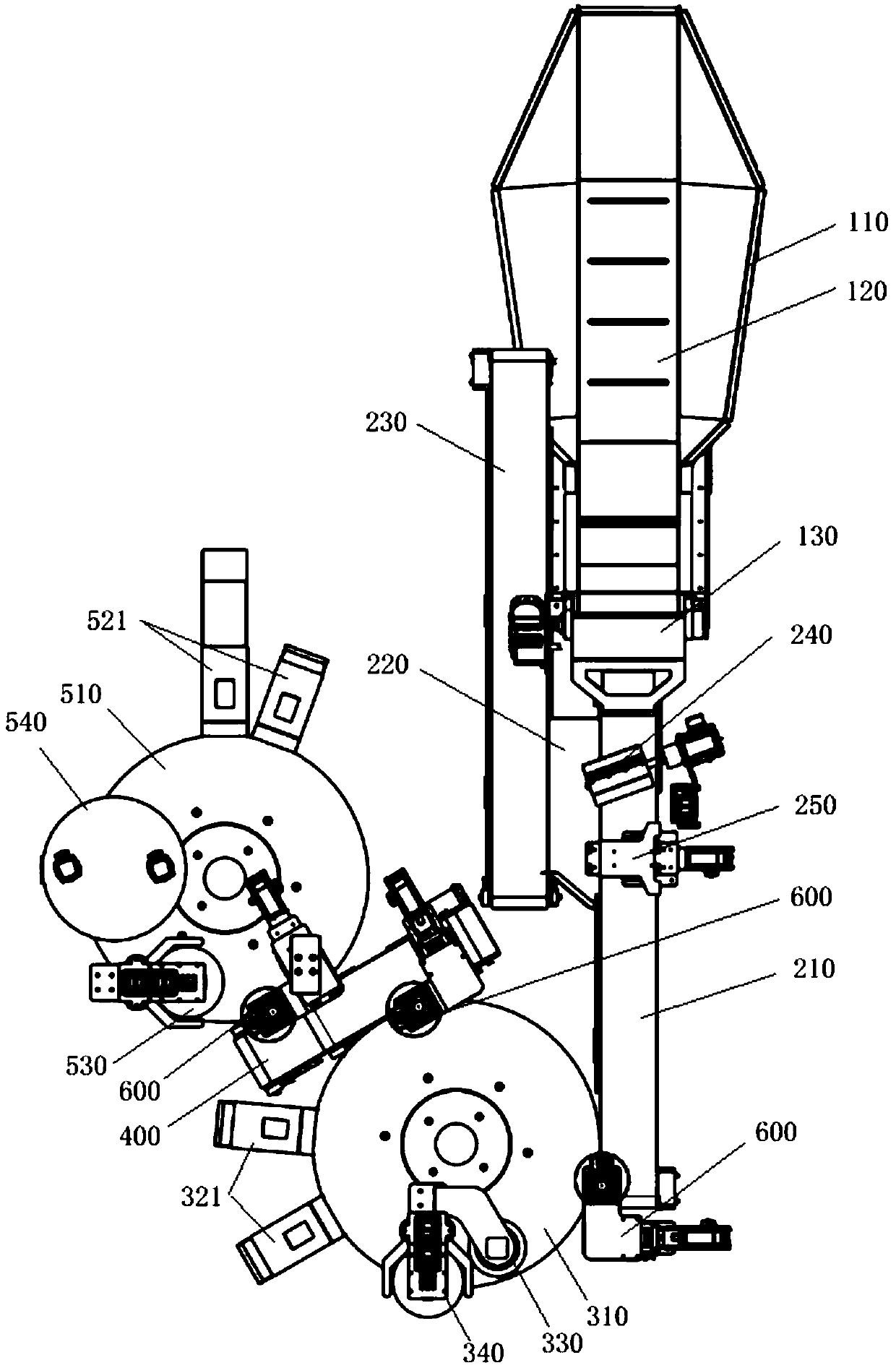

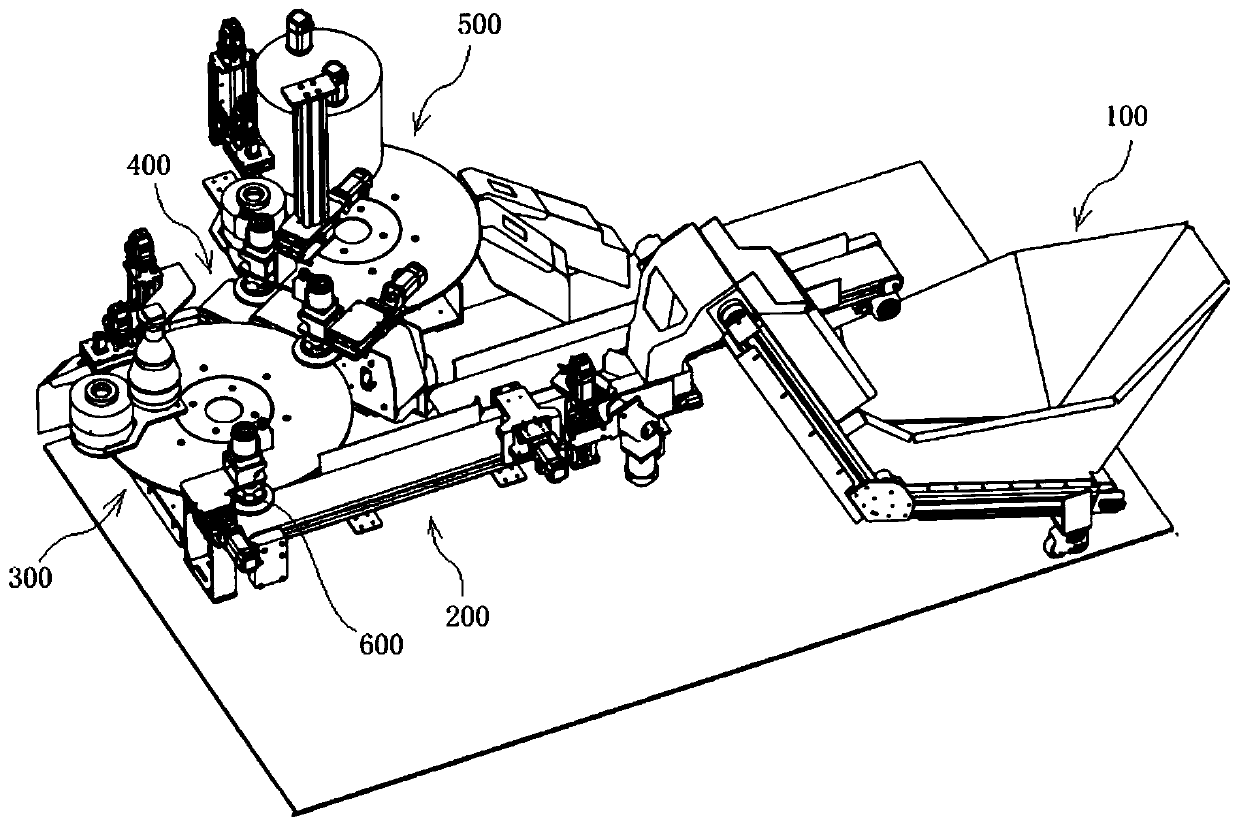

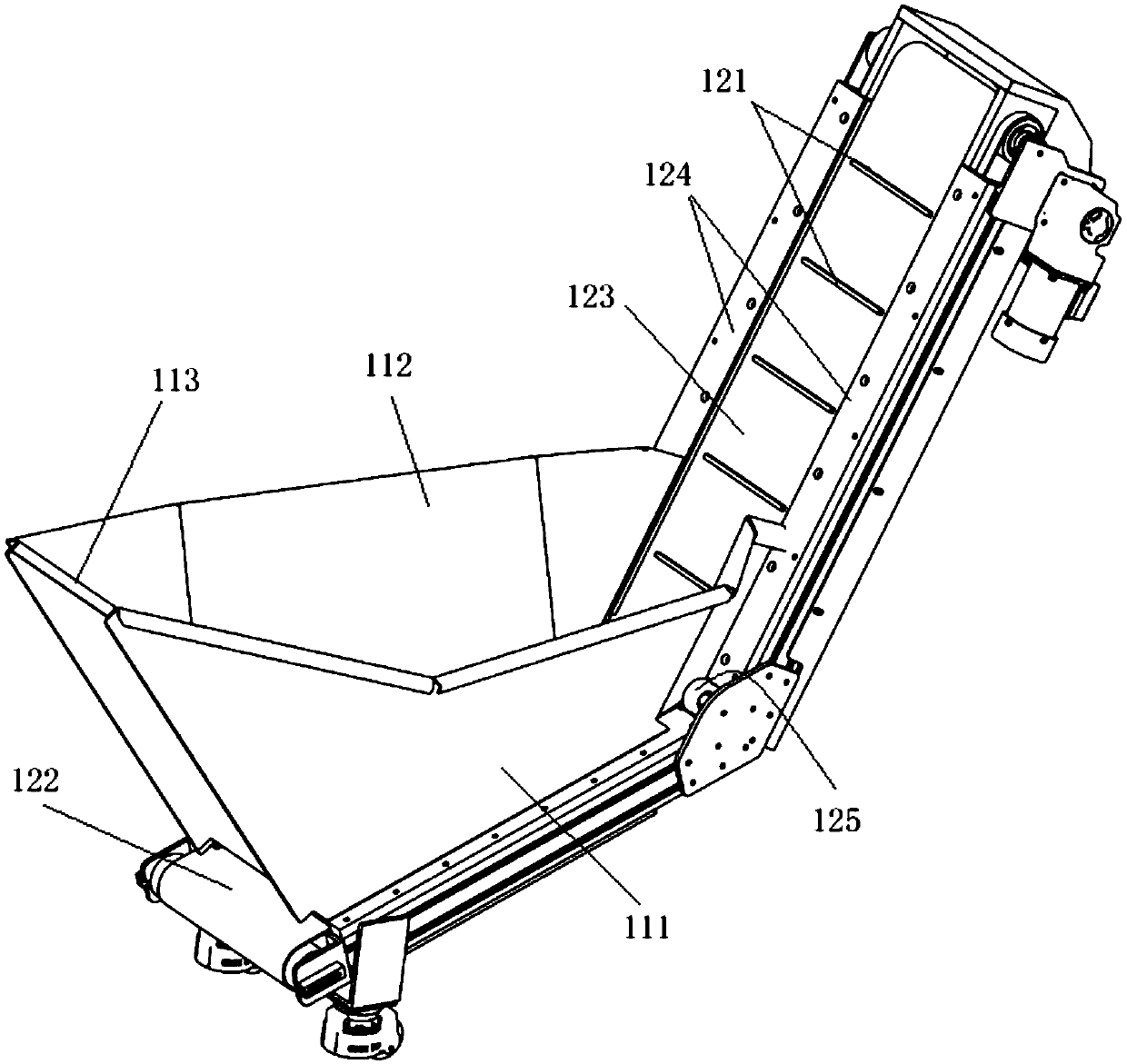

[0036] combined reference figure 1 and figure 2 , The component omnidirectional detection device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com