Automatic processing and assembling system and method for circuit board product

An assembly system and circuit board technology, applied in printed circuits, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problems of production line automation and production efficiency, low product quality and efficiency, and floor space Major problems, to achieve the effect of automatic and efficient production, stable product quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

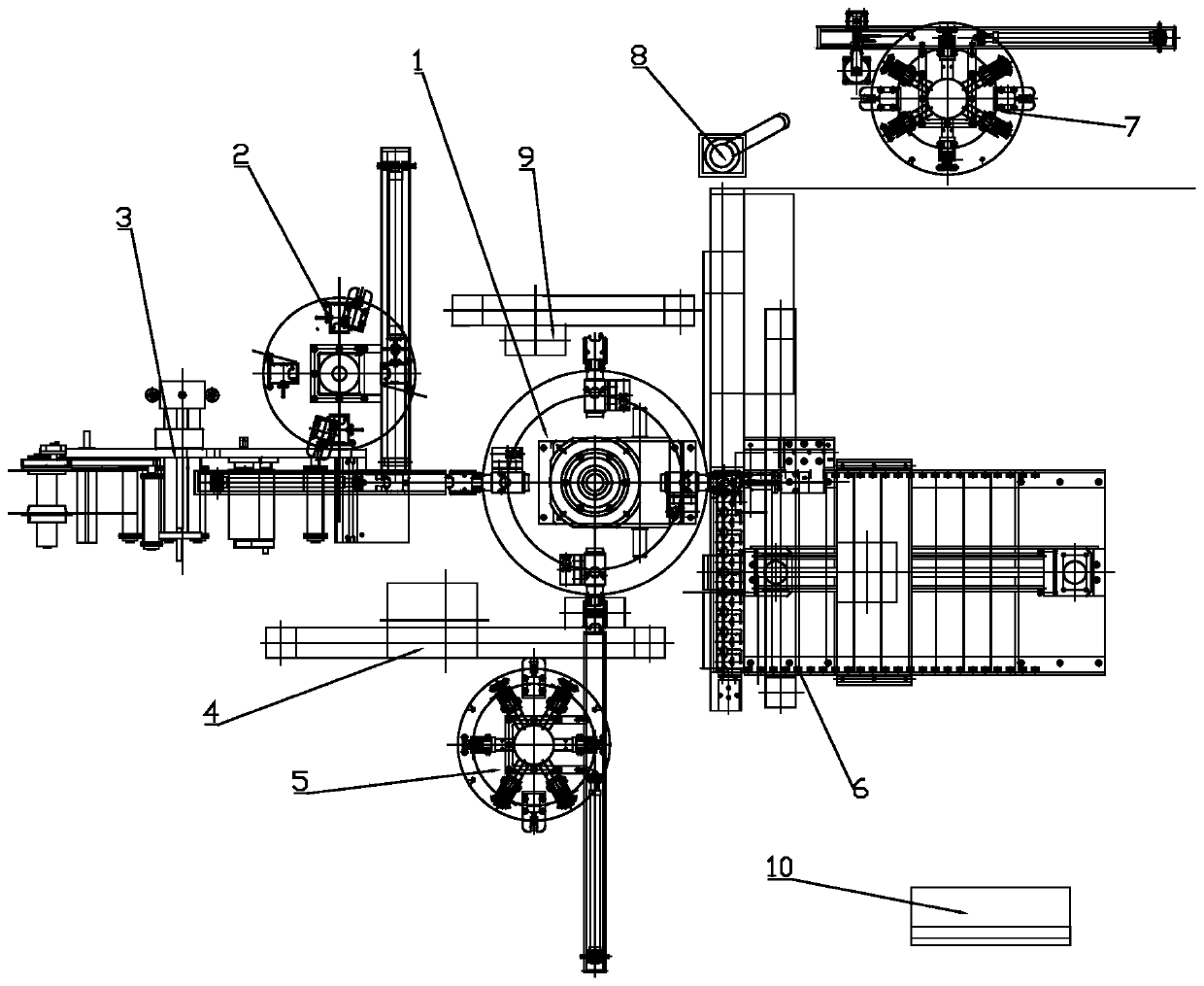

[0069] combine figure 1 As shown, the circuit board product automatic processing and assembly system provided by the present invention includes a central multi-station turntable mechanism 1, a bottom plate multi-cassette turntable feeding device 2, an automatic labeling machine 3, an automatic locking screw machine 4, and a base multi-cassette Turntable feeding device 5 , circuit board cavity magazine feeder rack feeding device 6 , component multi-cassette turntable feeding device 7 , assembly robot 8 , automatic soldering machine 9 and control system 10 .

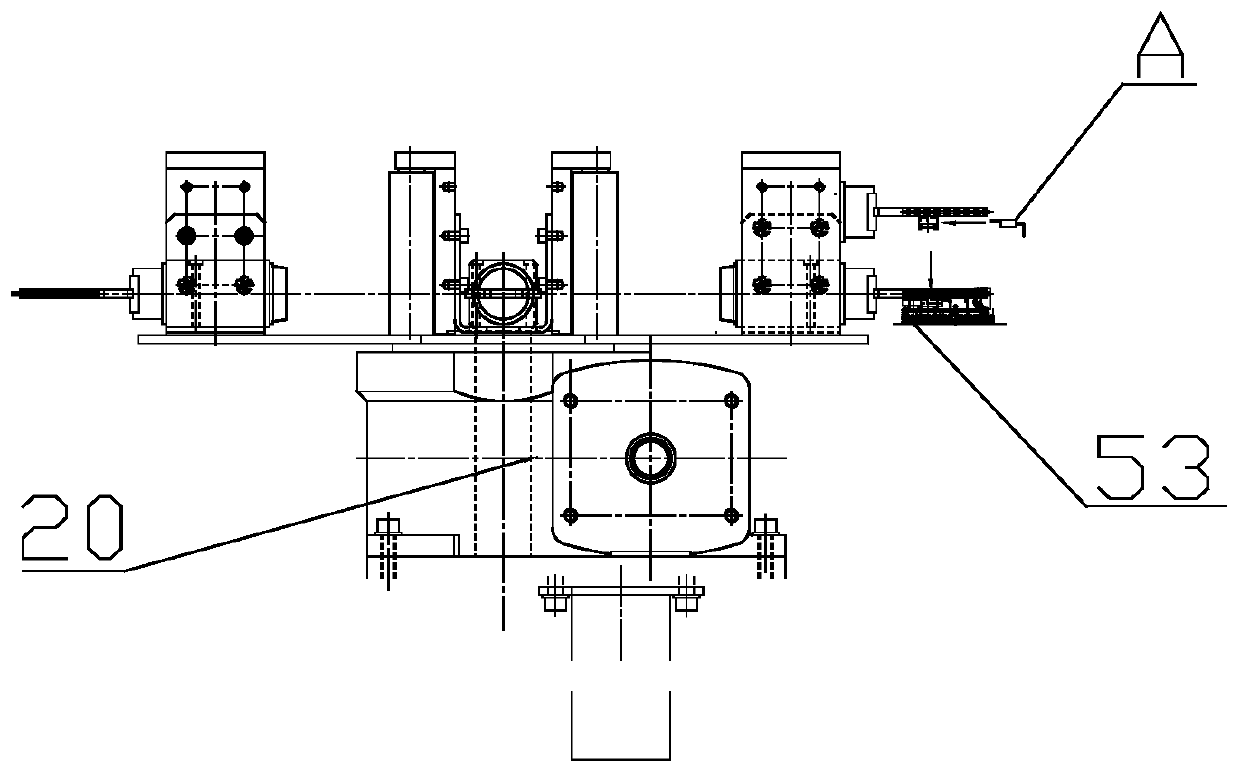

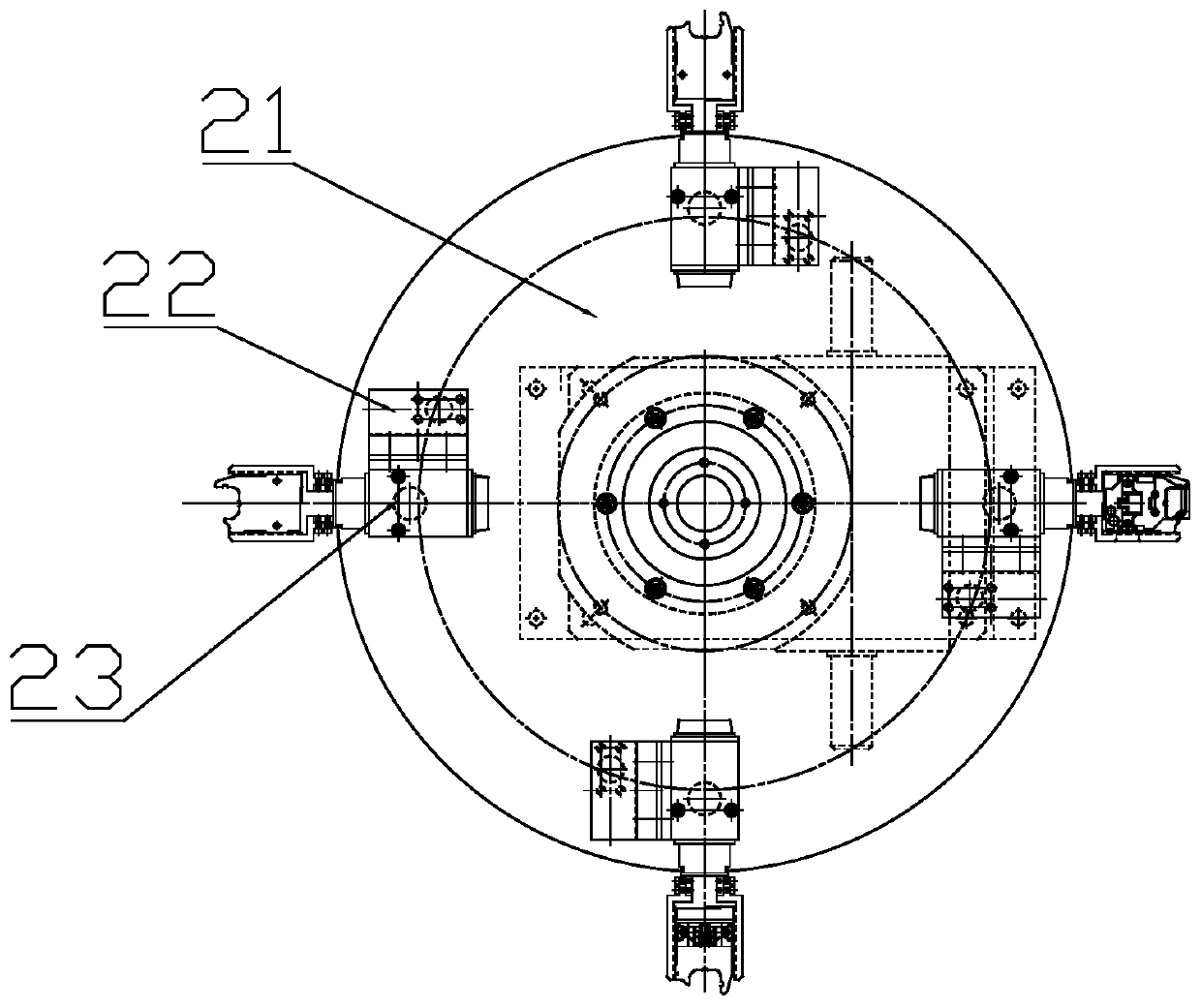

[0070] refer to figure 2 and image 3 , the central multi-station turntable mechanism 1 includes the No. 1 turntable 21 installed on the No. 1 divider 20, and the No. 1 turntable 21 has a bottom plate feeding and labeling station along the rotation direction, a screw locking station, and an assembler position and soldering station, each station is equipped with a station slide 22 and a jaw 23 that can move up and down a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com