Oilfield injection-production well hole finding ultrahigh-pressure deep-penetrating reaming equipment

An injection-production well, ultra-high pressure technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of reducing oil well injection capacity, increasing energy loss, increasing injection pressure, etc. Well zone damage, increase production degree, and improve the effect of liquid flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

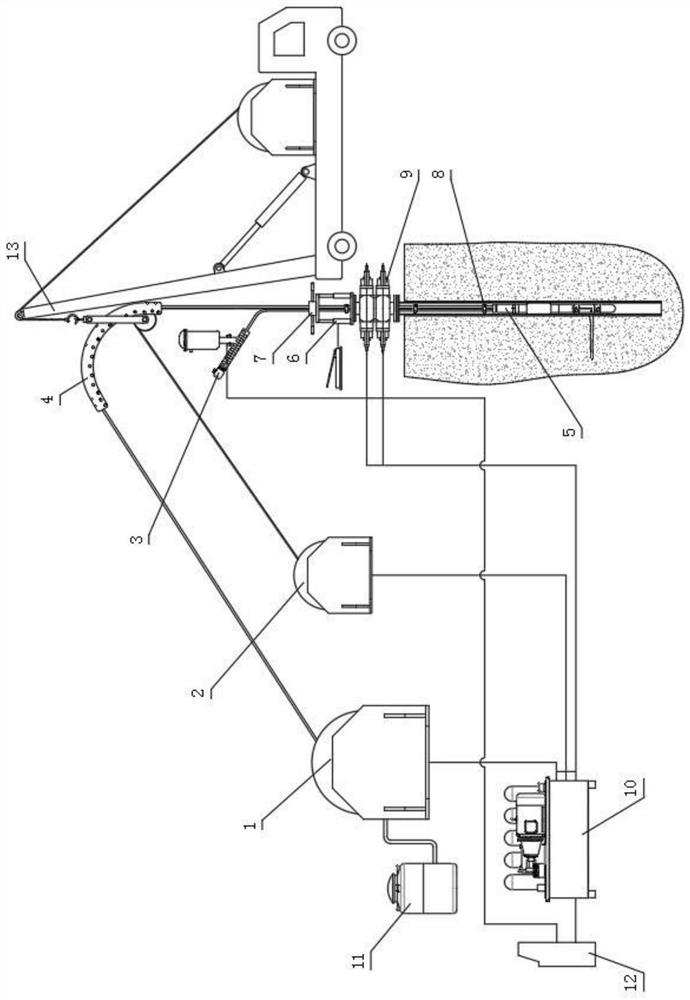

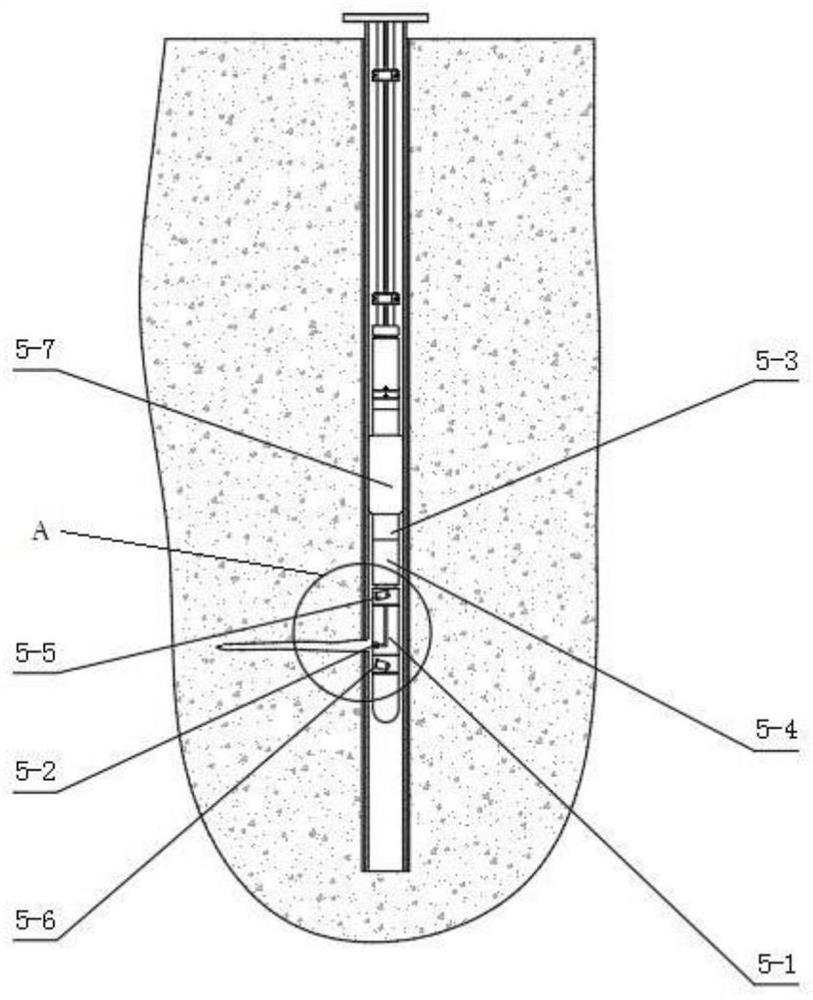

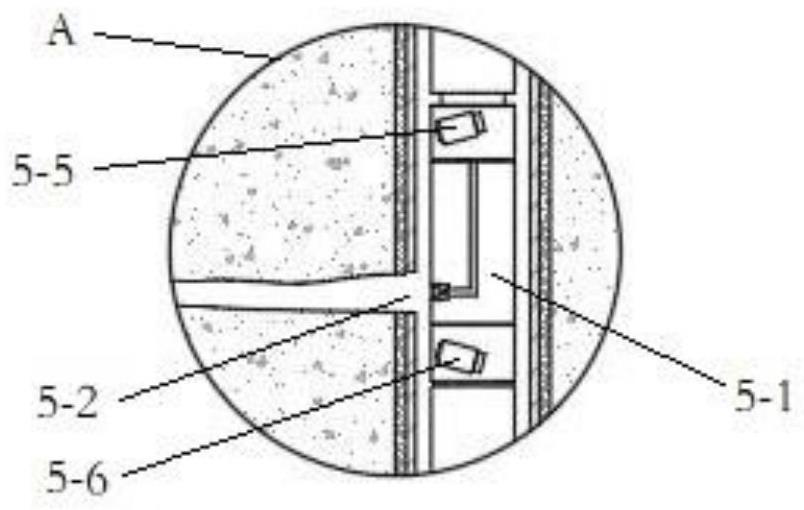

[0039] refer to Figure 1-Figure 6 , An ultra-high pressure deep penetration and reaming equipment for drilling injection and production wells in oilfields, including a high-pressure pipeline drum 1, a load-bearing steel cable retracting and unwinding drum 2, a high-pressure sander 3, an introduction device 4, an ultra-high-pressure jet device 5, and a height fine-tuning device. 6. Angle adjustment device 7, combined gripper 8, wellhead blowout preventer 9, hydraulic station 10, liquid distribution tank 11, control box 12 and crane 13; the introducer 4 is installed on the crane 13, the high pressure The high-pressure pipeline of the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com