Steel structure beam-column joint

A beam-column joint and steel structure technology, applied in building structure, construction, etc., can solve the problem of inconvenient disassembly and recycling of load-bearing columns and steel beams, and achieve the advantages of reducing hole-finding time, increasing stability, and convenient disassembly and recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

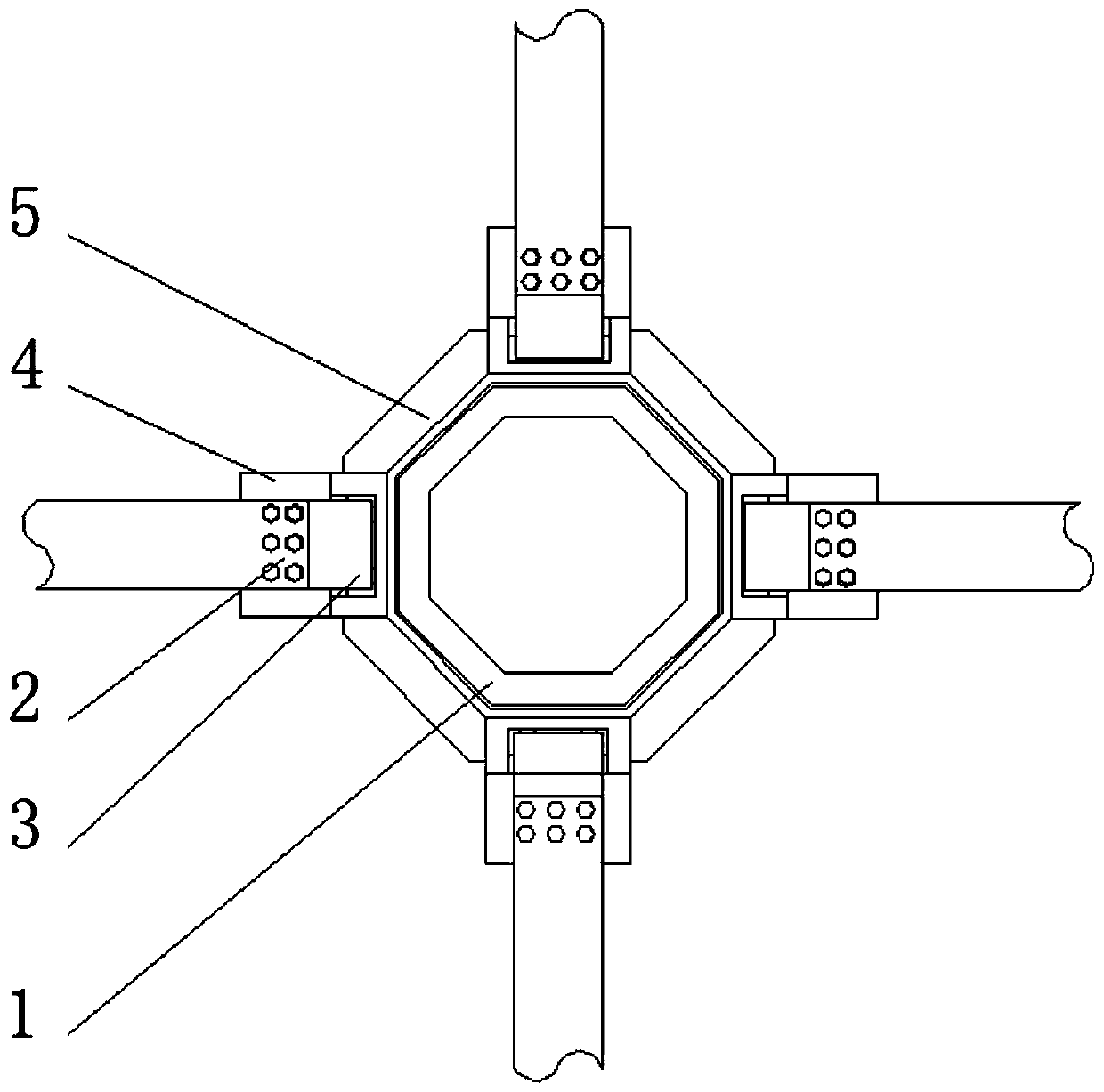

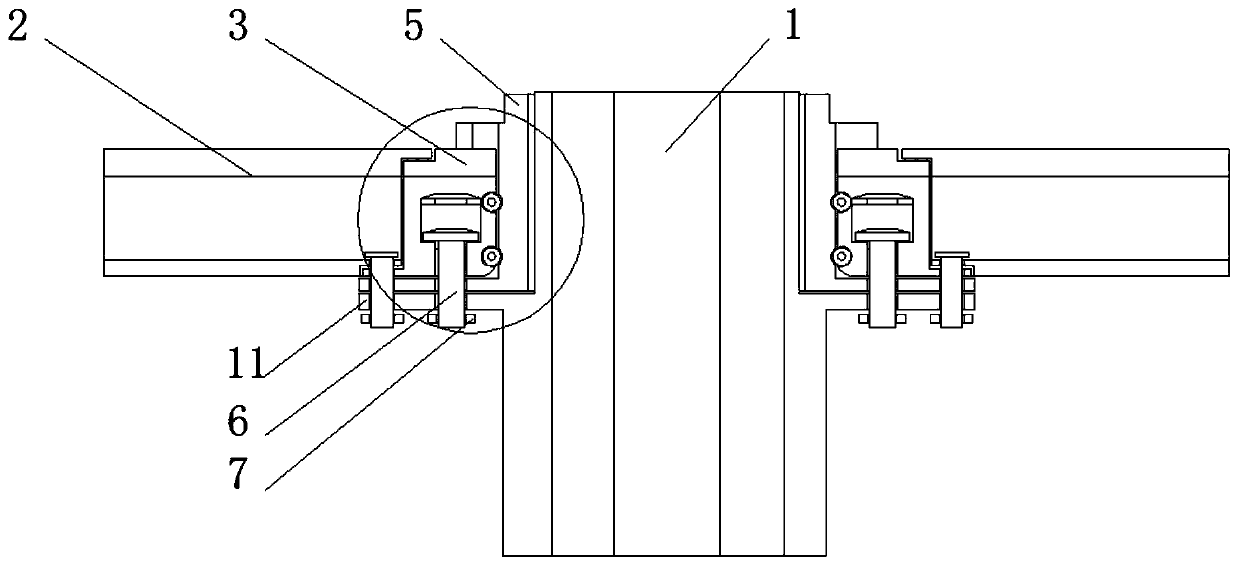

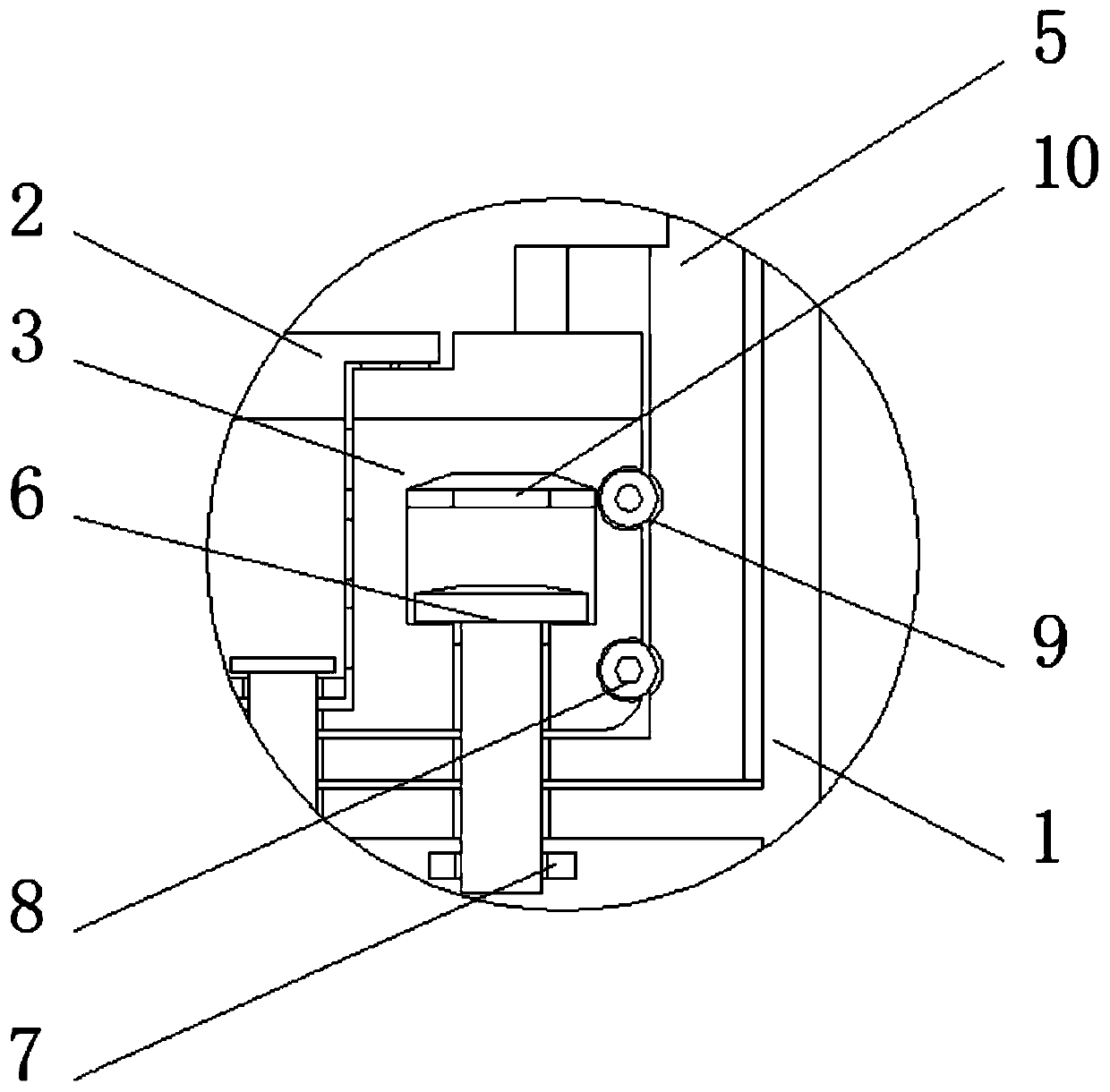

[0032] The invention provides a beam-column joint of a steel structure. The load-bearing column 1 adopts a steel column or a concrete steel pipe column, and the concrete steel pipe column adopts pouring concrete in the steel pipe column to form a component that the steel pipe and the concrete jointly bear the load;

[0033] Through the design of the protective steel sleeve 5 installed on the outside of the load-bearing column 1, and the buffer steel block 3 installed at the connection between the protective steel sleeve 5 and the steel beam 2, the extension of the connection node between the load-bearing column 1 and the steel beam 2 is realized. At the same time, it greatly facilitates the disassembly and recovery of the load-bearing column 1 and the steel beam 2. By designing the reinforcement bolt 6 installed in the buffer steel block 3, the steel beam 2, the load-bearing steel seat 4 and the load-bearing supporting plate 11 are realized. Pre-fixing reduces the time for find...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com