Fire hose connector

A technology for fire water pipes and pipe bodies, which is applied in the directions of pipes/pipe joints/fittings, threaded connections, passing elements, etc., can solve the problems of not being particularly suitable, insufficient length of water pipes, waste of materials, etc., to improve sealing and increase the density. , Increase the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

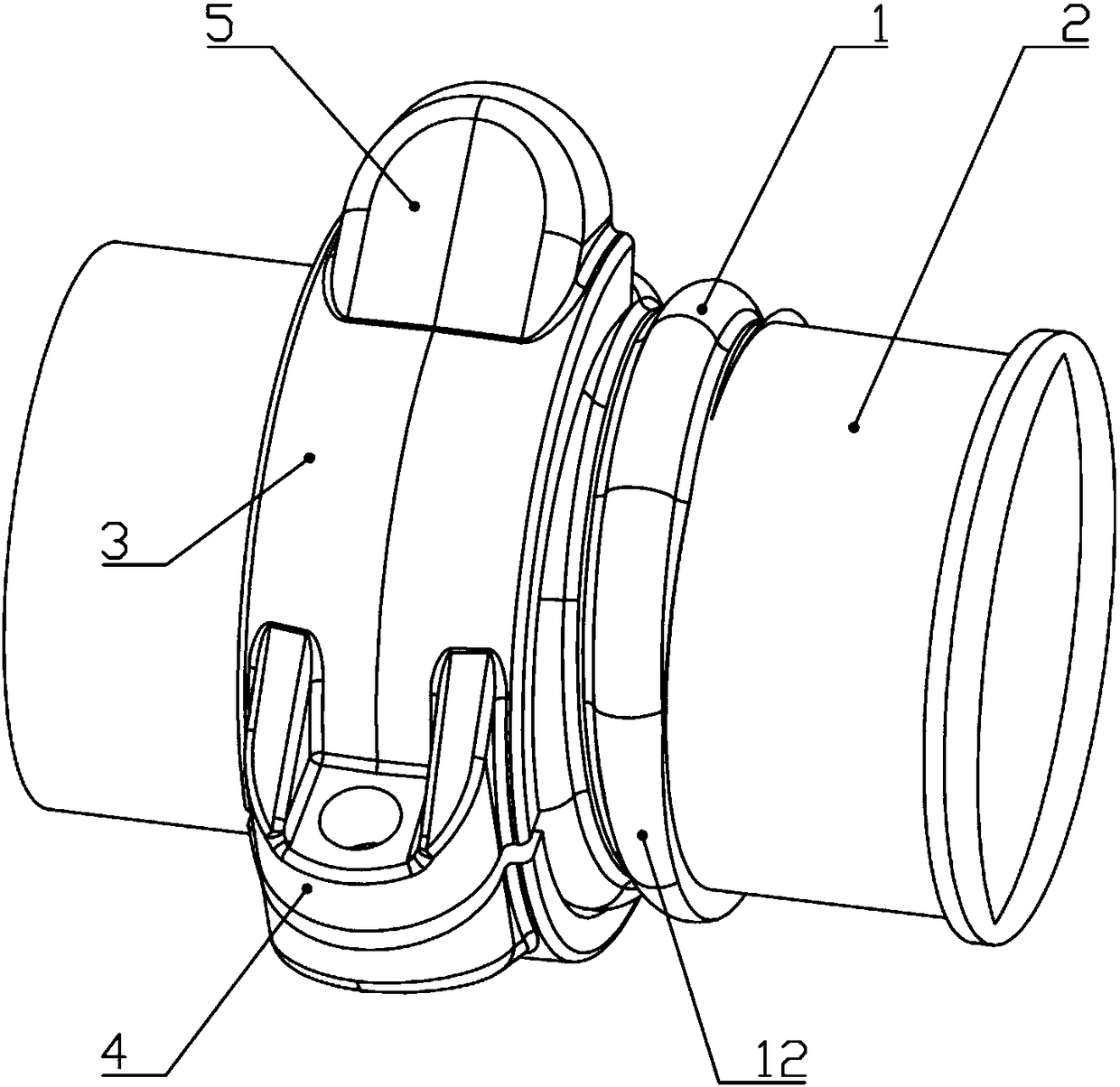

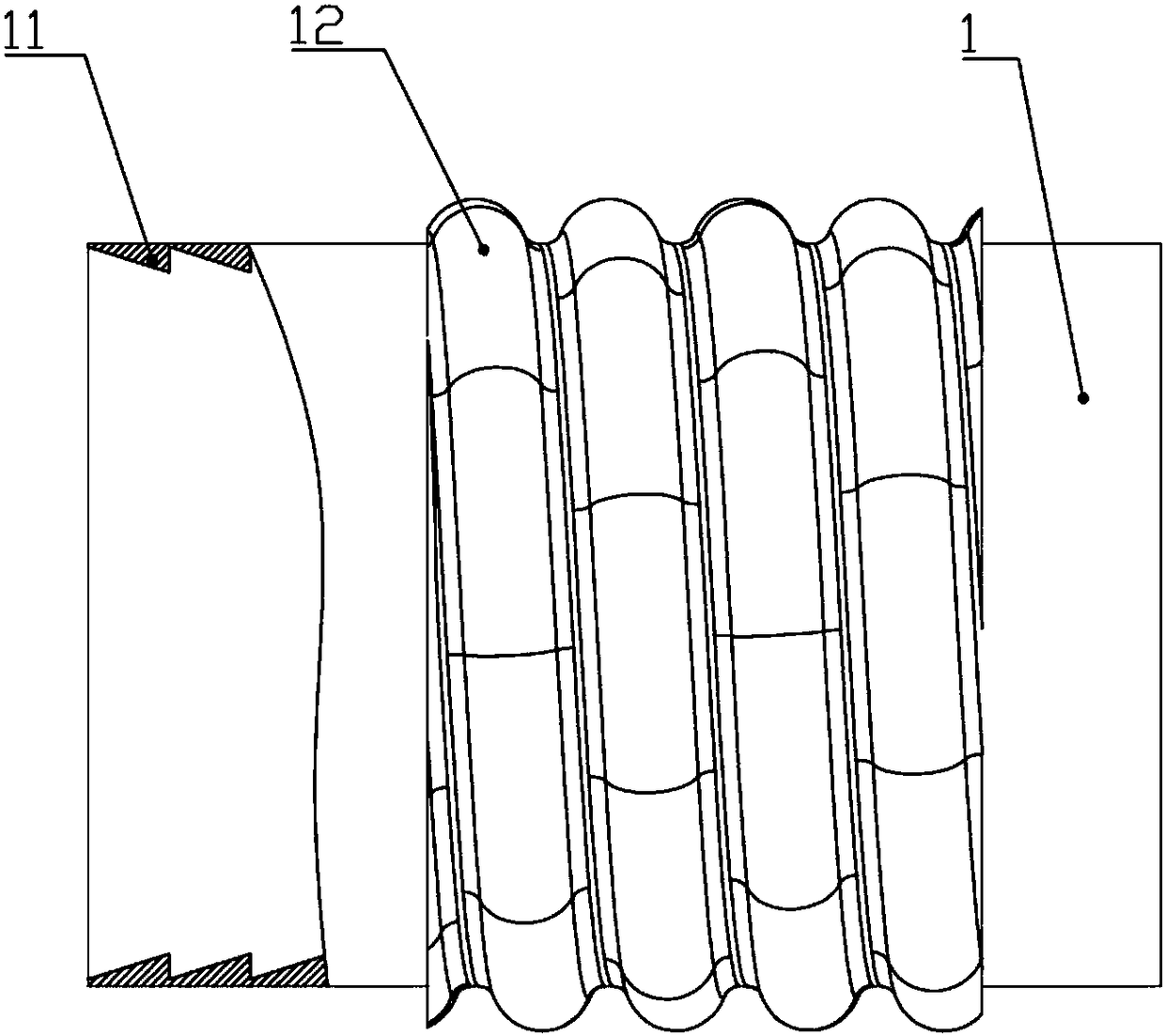

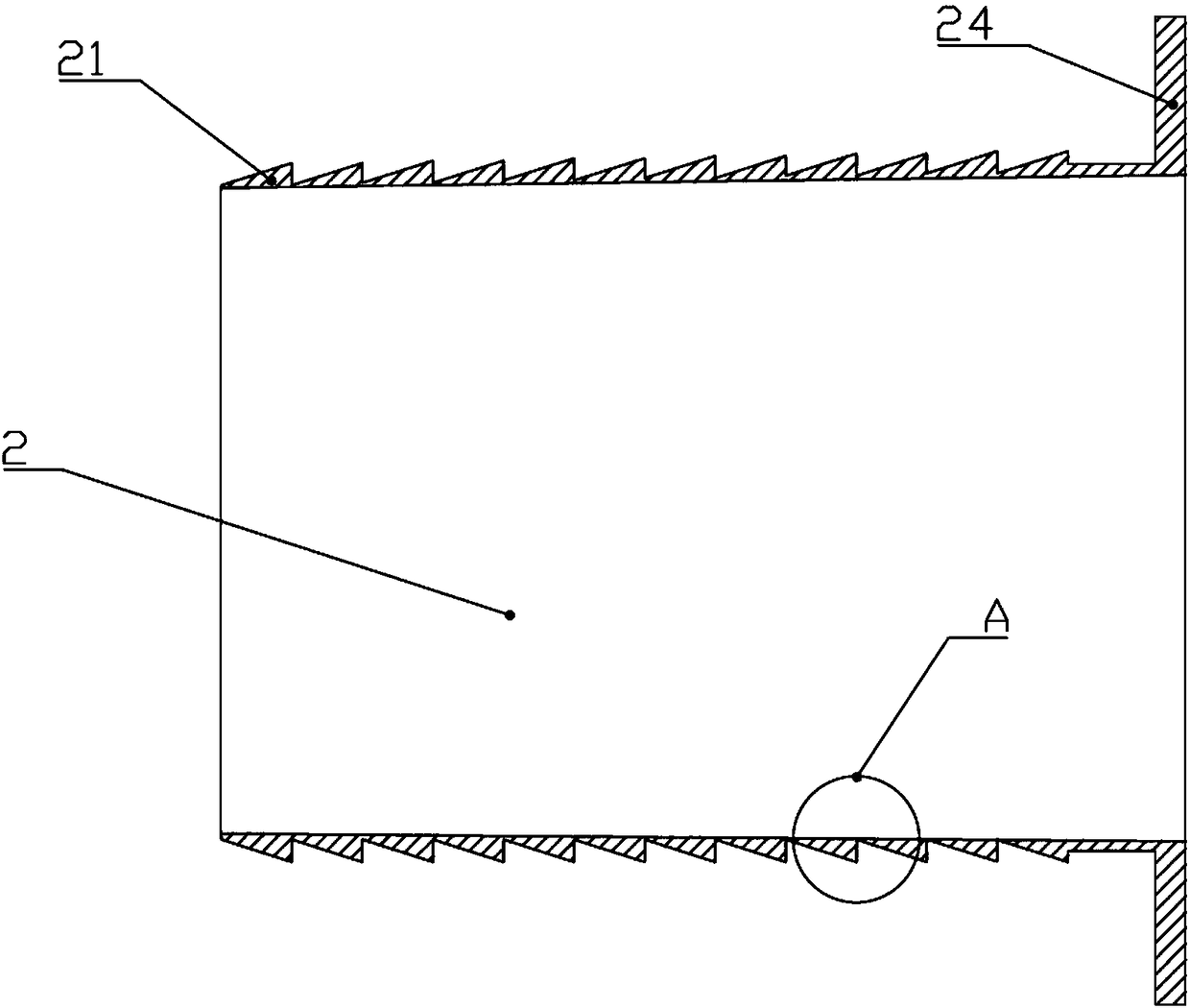

[0027] Embodiment one: if Figure 1-6 As shown, a fire-fighting water pipe joint includes a pipe body 1, and one end of a sleeve 2 is sleeved inside the pipe body 1; several channels for pre-fixing are arranged on the wall of the inner cavity of the pipe body 1. The sleeve 2 of the card slot 11 is provided with a snap ring 21 adapted to the card slot 11; the outer wall of the pipe body 1 is provided with a clamping member 3 composed of several two-by-two locking ferrules 31 , the clamping member 3 is used to clamp the outer wall of the tube body 1 and the sleeve 2 coincident. The size of the general sleeve 2 will be slightly larger than the inner diameter of the water pipe, so that the water pipe can be stretched when the sleeve 2 is inserted into the water pipe, so that a certain degree of sealing can be increased. Moreover, the cooperation of the clamping groove 11 and the clasp 21 can realize pre-fixation, and increase the stability of the connection between the sleeve 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com