Hole finding apparatus having integrated sensor and its method

A measurement device and wellbore technology, applied in electrical/magnetic detection, wellbore/well components, measurement, etc. for logging records, can solve problems such as incompatibility of technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

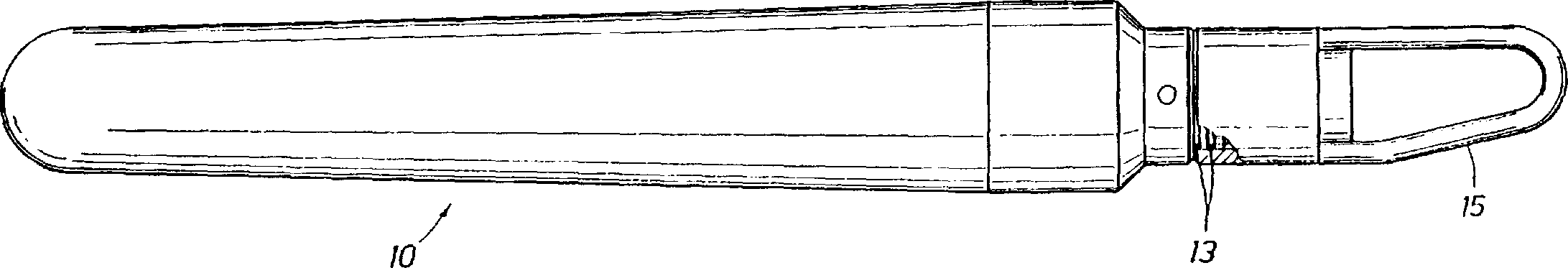

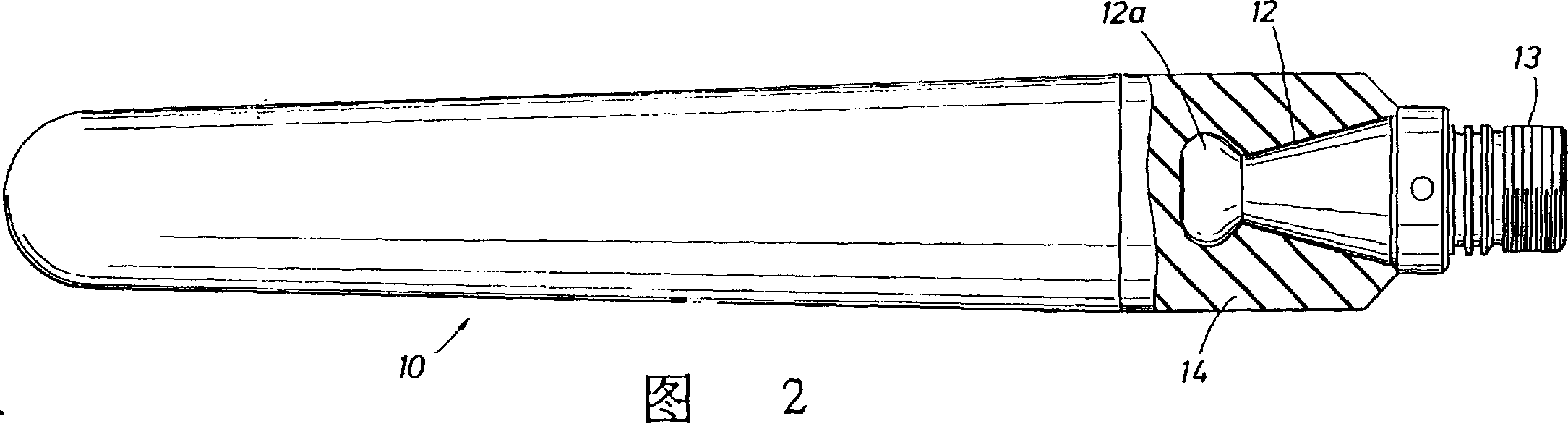

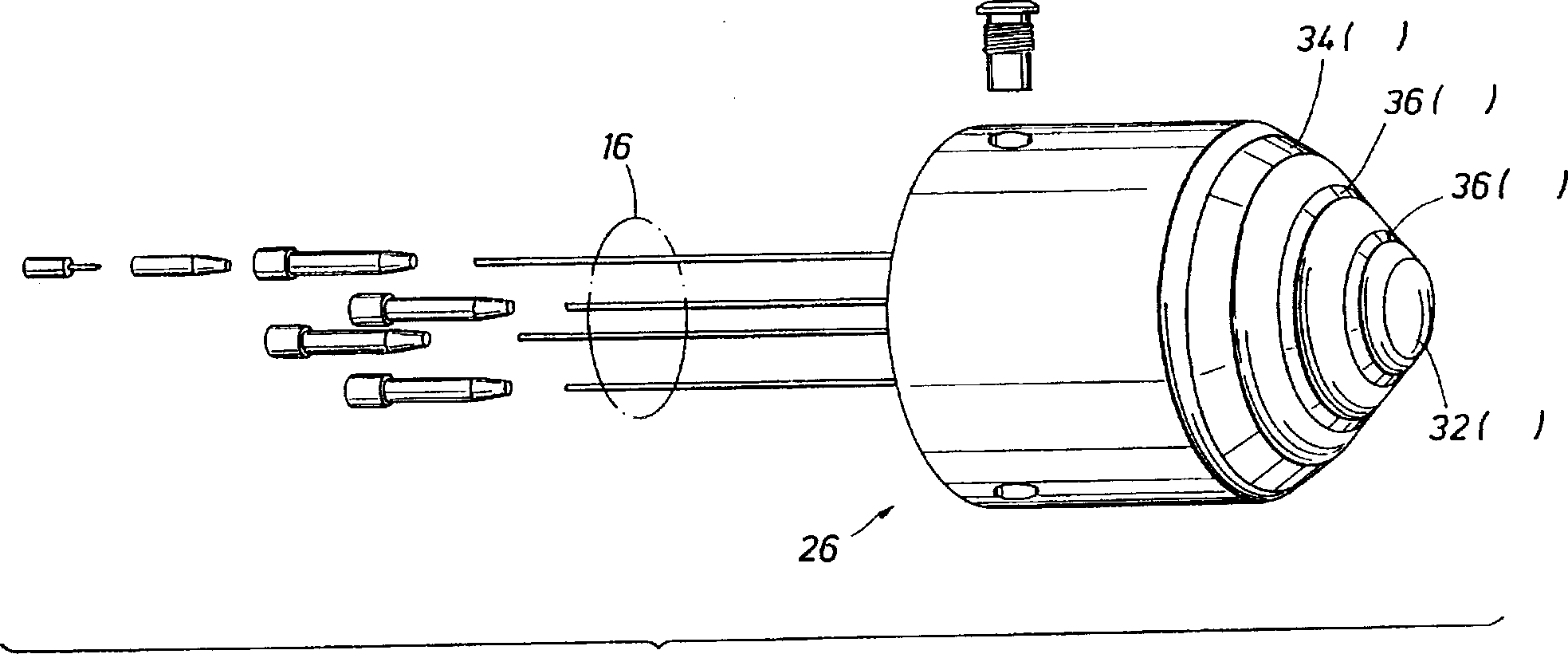

[0011] image 3 Shown is the probe described in US Pat. No. 5,574,371 to Tabanou et al., which may be incorporated into the tip of a wellbore sounding device. The disclosures of the above patents are hereby incorporated by reference. As shown in FIG. 4, the measurement probe 26 is firmly connected and bonded to the bottom (ie, the end) of the borehole detection device. For ease of description, this application is shown in image 3 The measuring probe 26 in to 5 bears the same reference numerals as the measuring probe in Fig. 5 of this US Pat. No. 5,574,371. The measuring probe 26 is suitable for use in filling mud boreholes to measure the natural potential Sp of the mud and the resistivity Rm of the liquid. When the logging instrument is placed in the borehole, the measurement probe 26 includes: a bottom electrode 32 (A 0 ), a second electrode 34 (A 1 ), and at least one placed on the bottom electrode 32 (A 0 ) nearby and used to measure the potential drop of a region of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com