Full-automatic anti-loosening ball assembling machine for outer spherical ball bearing

A technology for outer spherical surfaces and ball bearings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large labor force, high rate of defective products, and low efficiency, so as to reduce labor intensity, improve work efficiency and The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation manner described in this embodiment. The purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the disclosure of the present application, wherein the words indicating orientation such as up, down, left, and right are only for the positions of the structures shown in the corresponding drawings.

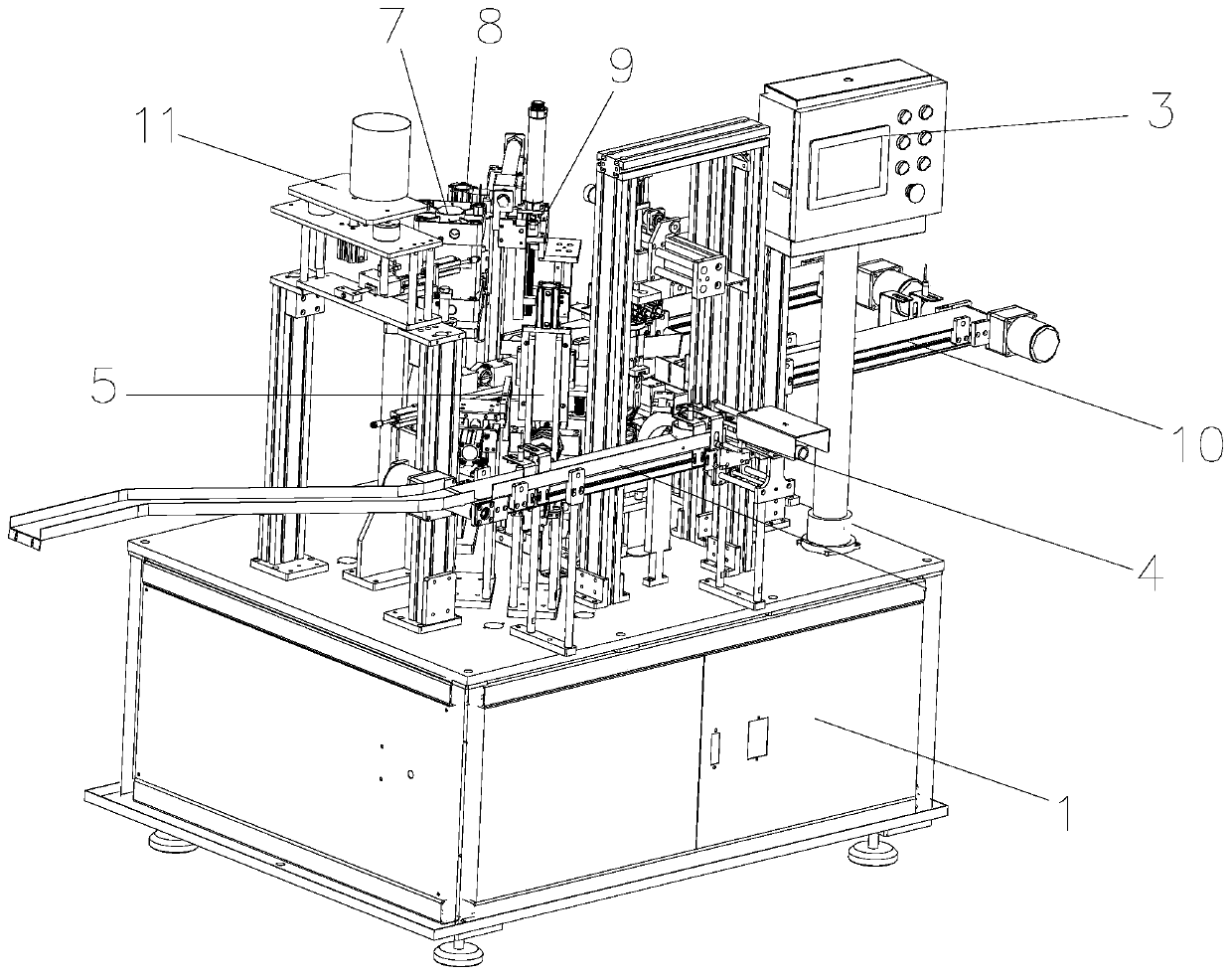

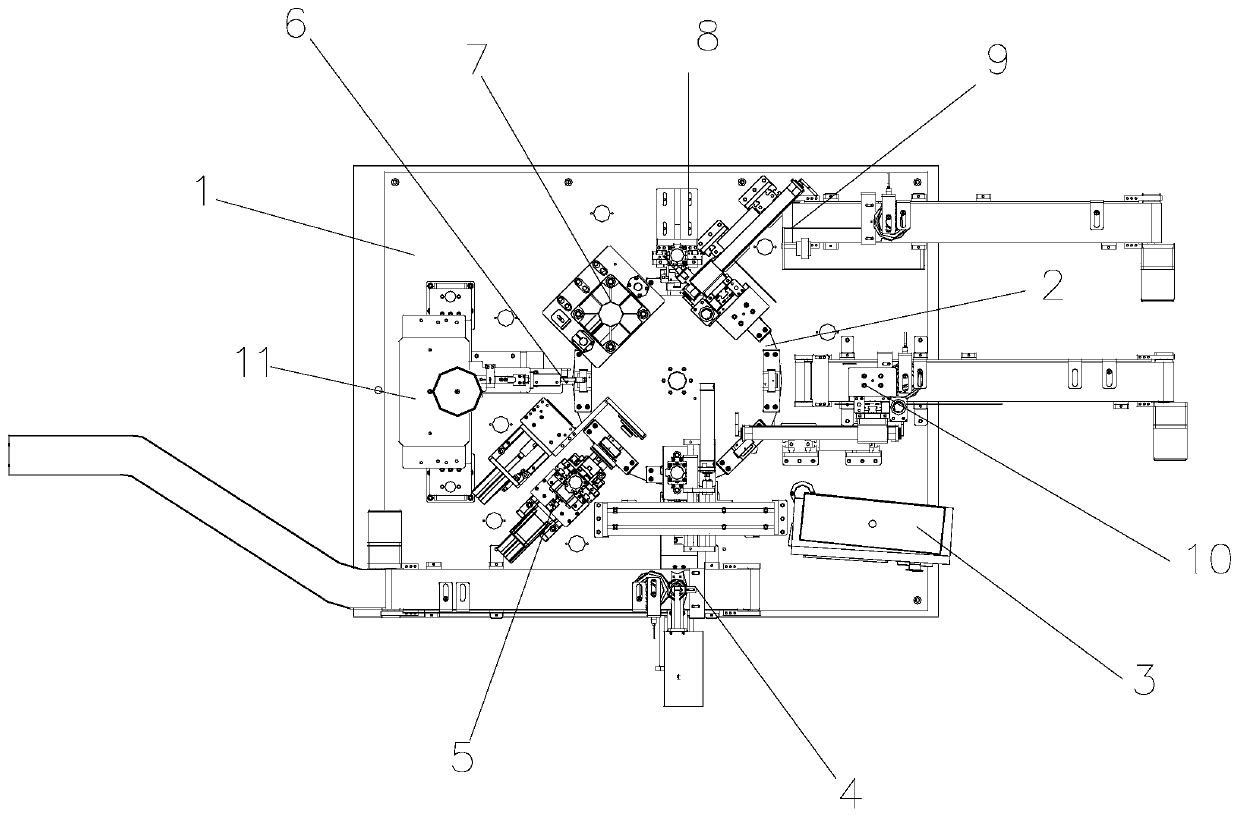

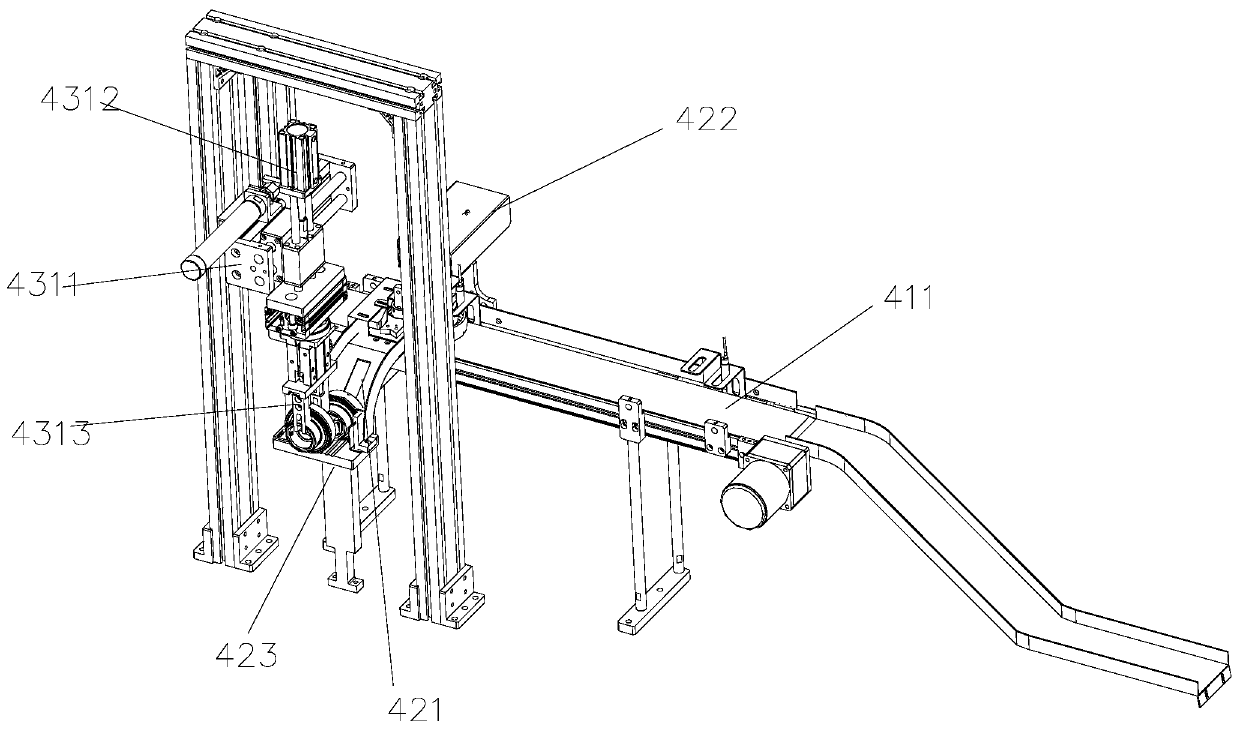

[0039] see Figure 1-2 with Figure 13 As shown, the present invention relates to a fully automatic outer spherical ball bearing anti-loosening ball assembly machine, including a cabinet 1, a turntable mechanism 2 arranged on the cabinet 1, a control box 3, and a feeding mechanism 4 arranged in turn around the turntable mechanism 2 , hole-seeking mechanism 5, ball loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com