Adjustable yarn guiding frame for polyester monofilaments

An adjustable technology of polyester monofilament, which is applied in the field of adjustable wire guides, can solve the problems of easy slack and entanglement of silk threads, affecting the spinning and appearance of silk threads, and poor positioning and guiding effects, so as to avoid thread prolapse and damage Small, guaranteed clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

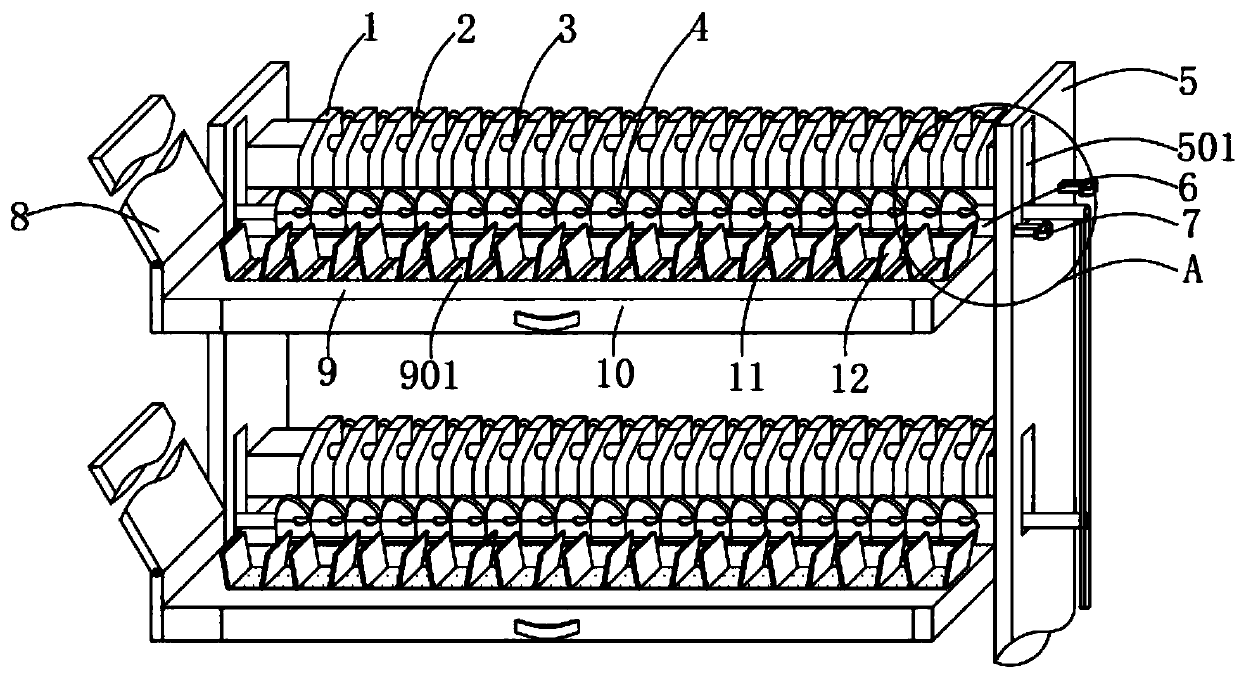

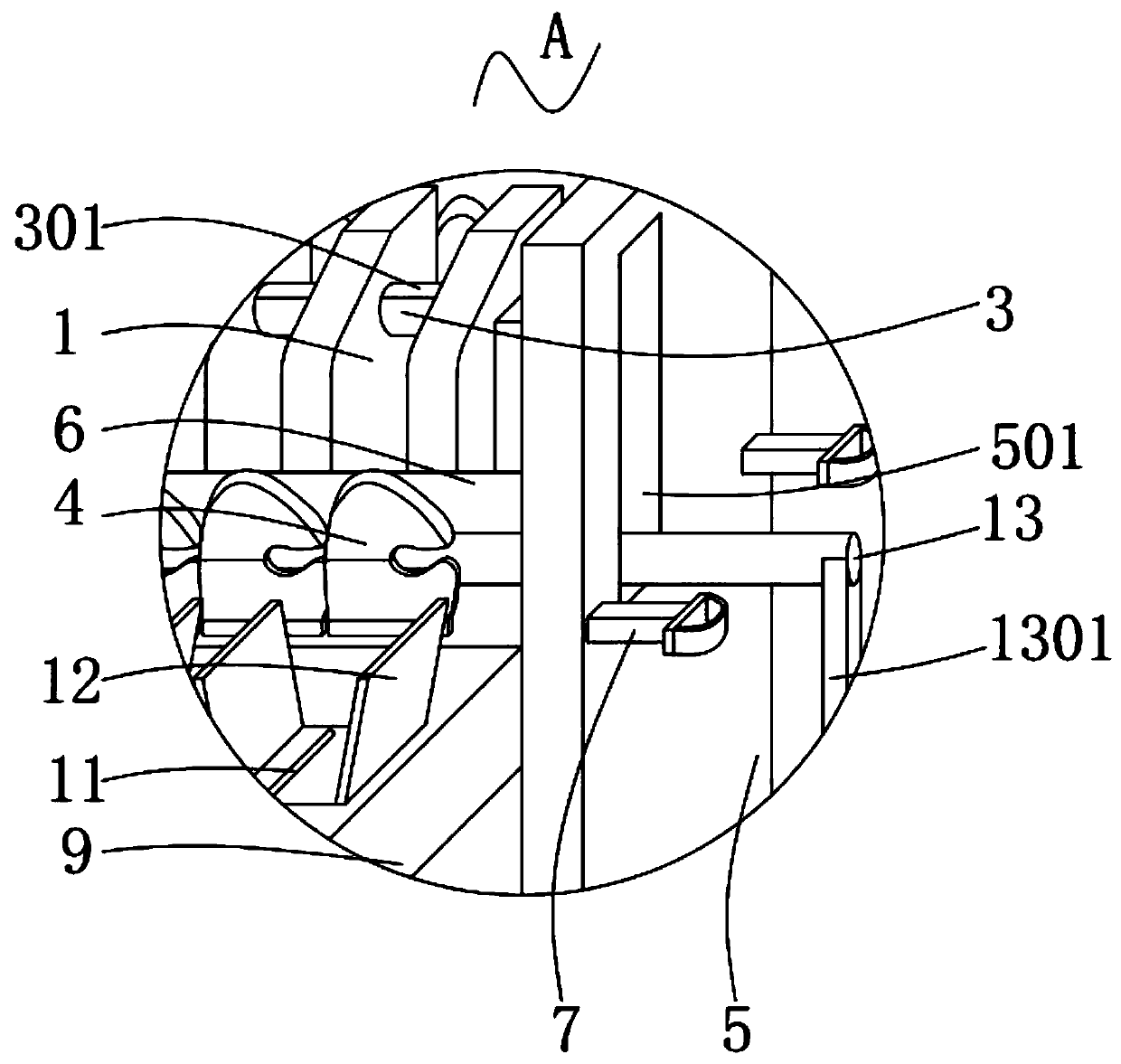

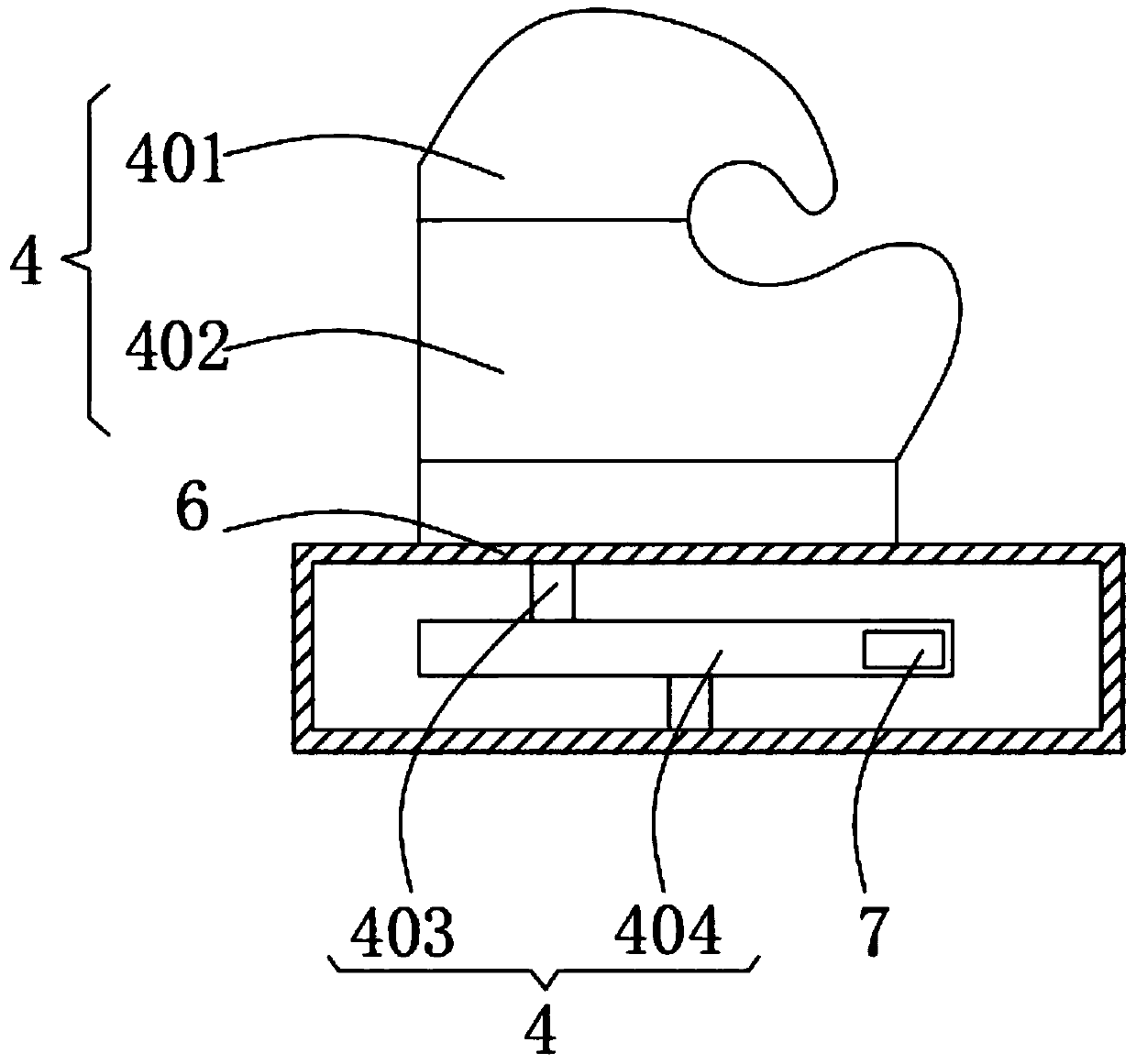

[0023] Such as Figure 1-4 As shown, an adjustable guide frame for polyester monofilament includes side baffles 5, a base 6 is fixed between the two side baffles 5, and several tops of the base 6 are equidistantly fixed. Limiting plate 1; between the limiting plates 1 are connected by a godet 3, and one side of every two limiting plates 1 is provided with a first limiting frame 2; every two limiting The other side of the plate 1 is provided with a second limit frame 4 with the same structure as the first limit frame 2, and the first limit frame 2 and the second limit frame 4 are fixed on the At the edges of both sides of the base 6; the second limit frame 4 includes a rotating rod 404, the rotating rod 404 is rotatably connected to the inside of the base 6, and the end of the rotating rod 404 passes through the fixed pull rod 7. The other end of the rotating rod 404 is fixed to the rotating shaft 403, and the rotating shaft 403 is connected to the movable part 401 through the...

Embodiment 2

[0027] Such as Figure 1-4 As shown, an adjustable guide frame for polyester monofilament includes side baffles 5, a base 6 is fixed between the two side baffles 5, and several tops of the base 6 are equidistantly fixed. Limiting plate 1; between the limiting plates 1 are connected by a godet 3, and one side of every two limiting plates 1 is provided with a first limiting frame 2; every two limiting The other side of the plate 1 is provided with a second limit frame 4 with the same structure as the first limit frame 2, and the first limit frame 2 and the second limit frame 4 are fixed on the At the edges of both sides of the base 6; the second limit frame 4 includes a rotating rod 404, the rotating rod 404 is rotatably connected to the inside of the base 6, and the end of the rotating rod 404 passes through the fixed pull rod 7. The other end of the rotating rod 404 is fixed to the rotating shaft 403, and the rotating shaft 403 is connected to the movable part 401 through the...

Embodiment 3

[0031] Such as Figure 1-4 As shown, an adjustable guide frame for polyester monofilament includes side baffles 5, a base 6 is fixed between the two side baffles 5, and several tops of the base 6 are equidistantly fixed. Limiting plate 1; between the limiting plates 1 are connected by a godet 3, and one side of every two limiting plates 1 is provided with a first limiting frame 2; every two limiting The other side of the plate 1 is provided with a second limit frame 4 with the same structure as the first limit frame 2, and the first limit frame 2 and the second limit frame 4 are fixed on the At the edges of both sides of the base 6; the second limit frame 4 includes a rotating rod 404, the rotating rod 404 is rotatably connected to the inside of the base 6, and the end of the rotating rod 404 passes through the fixed pull rod 7. The other end of the rotating rod 404 is fixed to the rotating shaft 403, and the rotating shaft 403 is connected to the movable part 401 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com