Steel wire rope cutting-off, clamping, correcting and tensioning combined device and using method

A technology of combining device and steel wire rope, applied in the field of steel wire rope, can solve the problems of complex structure, single function of the device, not suitable for automatic production line, etc., and achieve the effect of good structural combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

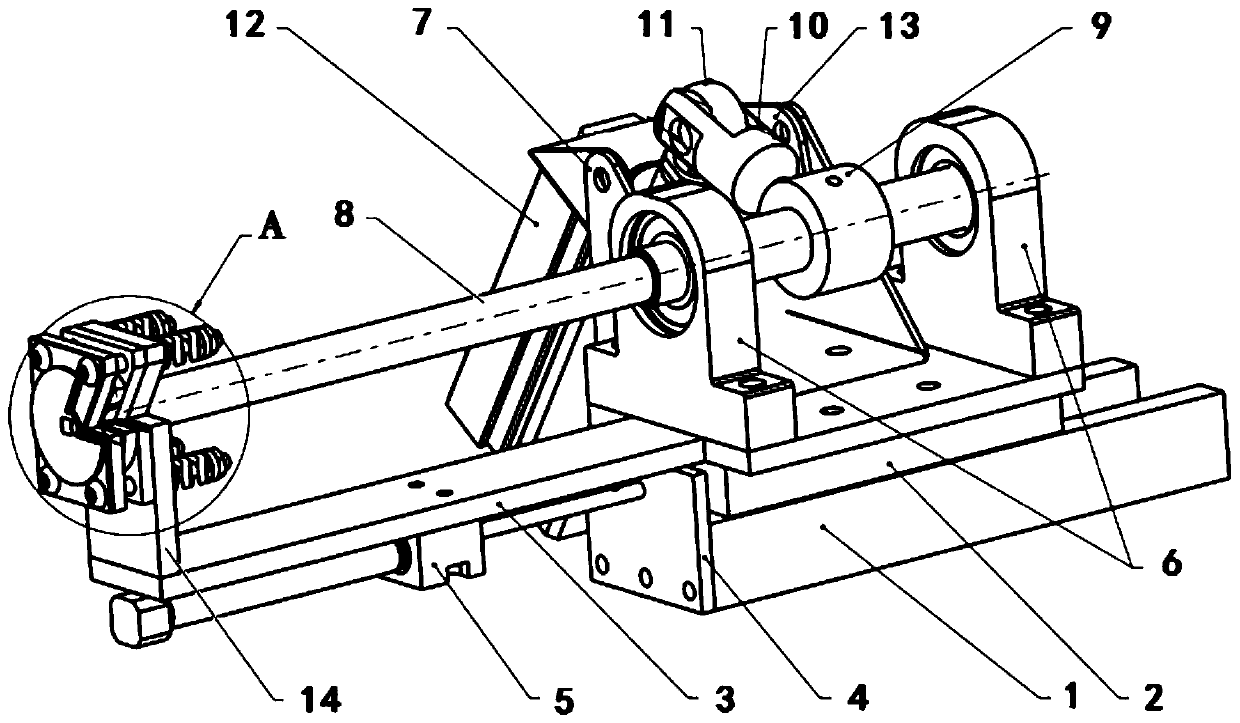

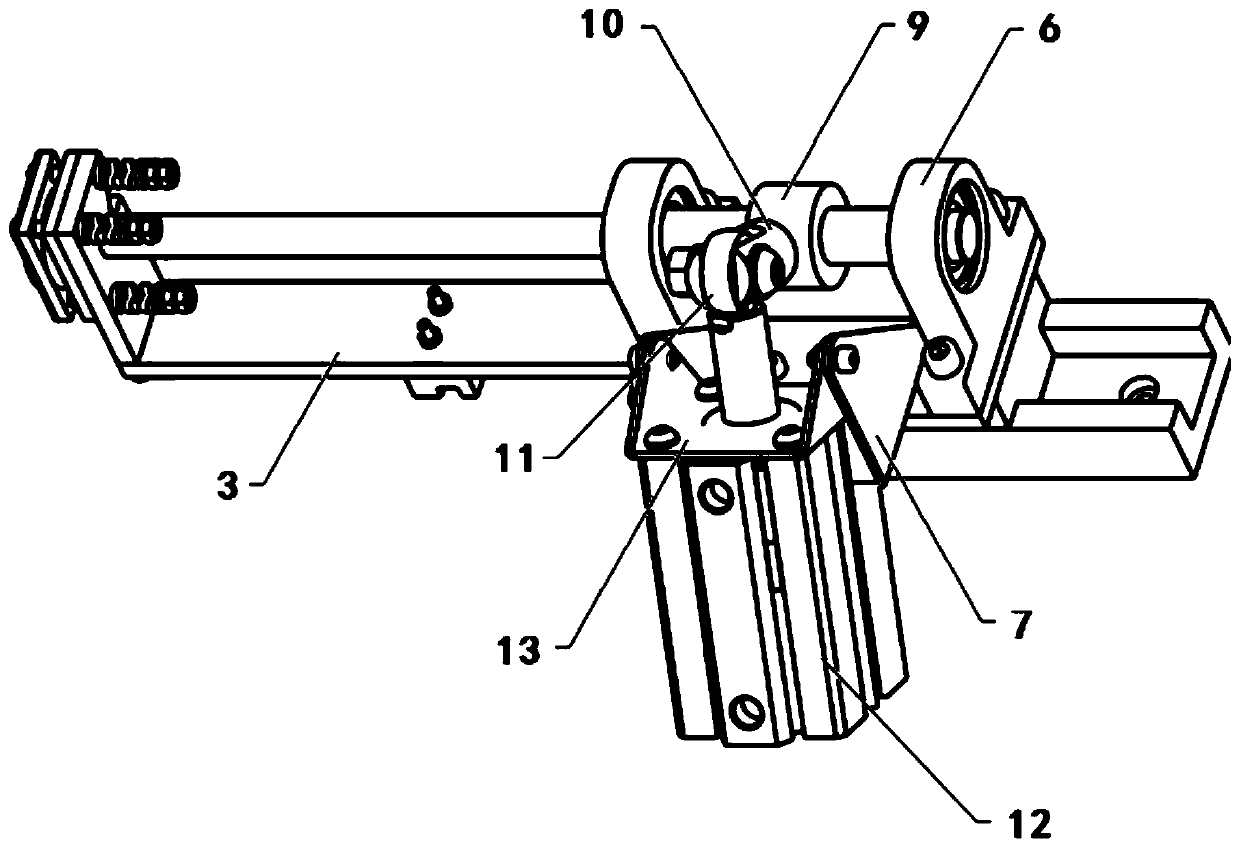

[0052] In Embodiment 1, a device structure capable of fully realizing all functions of cutting, clamping, straightening, and tensioning is provided.

[0053] Such as figure 1 As shown, the device includes a guide rail 1 fixedly installed on the substrate, a guide rail slide 2 is installed on the guide rail 1, the guide rail slide 2 can slide linearly on the guide rail 1, and a relatively long guide rail slide 2 is fixedly installed on the top Mounting plate 3; a piston rod mounting plate 4 is fixed at one end of the guide rail 1, the piston rod of the No. 1 cylinder 5 is fixed on the piston rod mounting plate 4, and the cylinder body of the No. 1 cylinder 5 is fixed at the bottom of the mounting plate 3. When the cylinder 5 is working , due to the reaction of the force, the piston rod does not move, and the cylinder moves, which in turn drives the mounting plate 3 and the guide rail slide table 2 to slide. The advantages of this design are: one, the fixed support parts of the...

Embodiment 2

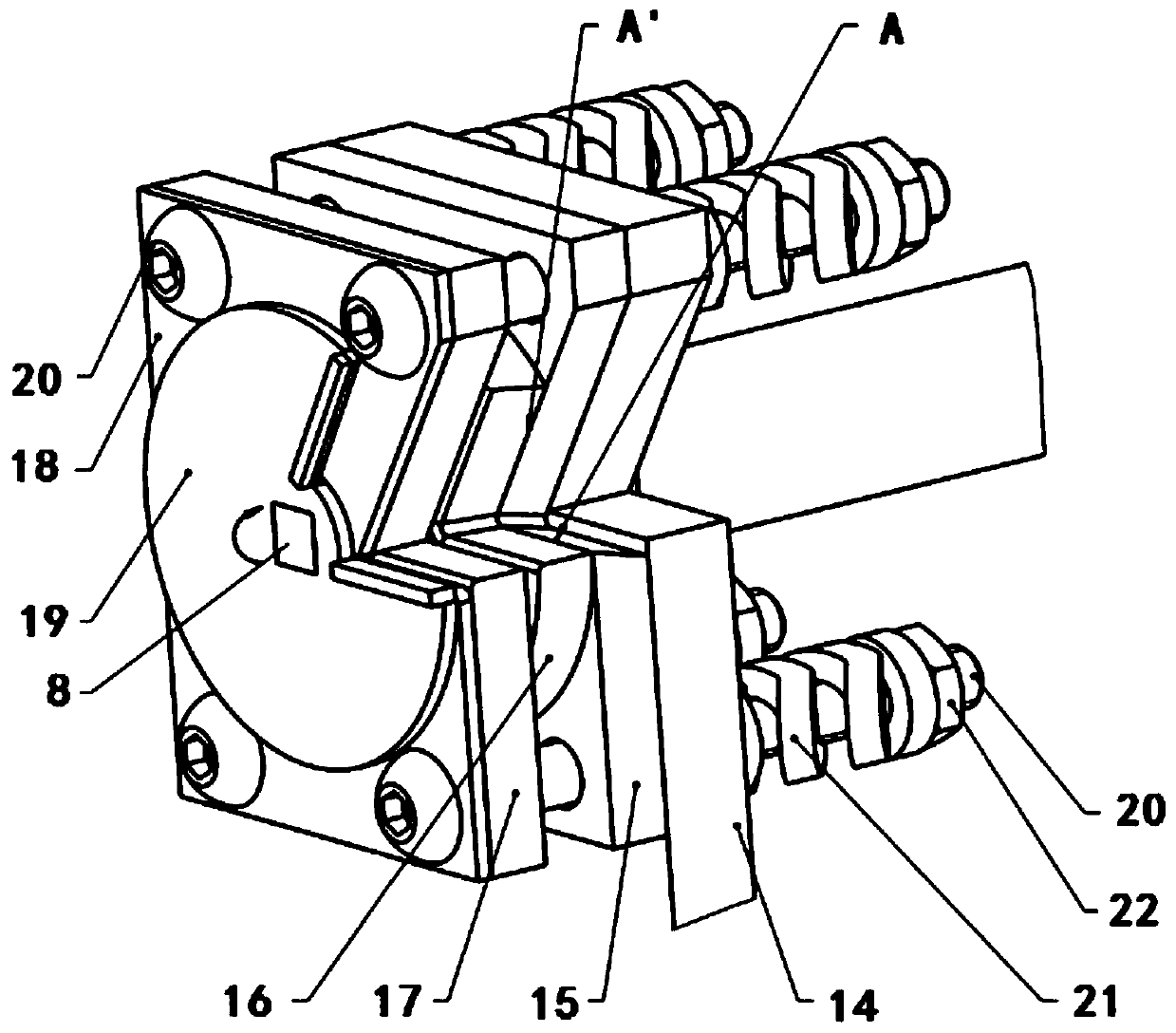

[0087] In embodiment 2, a device structure for realizing cutting, clamping and tensioning is provided, such as Figure 7 shown.

[0088] The difference between embodiment 2 and embodiment 1 is that the correction plate 1 18 and correction plate 2 19 are removed, and the shaft end of the rotating shaft in the cutting and clamping assembly is installed to cut and clamp the supporting plate 14, cut off the clamping plate 15, cut off the clamping plate 16, Clamping plate 17 , bolt 20 , spring 21 and nut 22 .

[0089] Refer to Example 1 for the method of use. The cutting and clamping support plate 14 is installed with a plurality of bolts to cut off the cutting plate 15, the cutting and clamping plate 16, the clamping plate 17, the spring 21 and the nut 22, which do not move with the rotating shaft; the spring 21 is used to adjust the cutting The clamping between the plate 15 and the clamping plate 17 cuts off the pre-tightening force of the clamping plate 16; the rotation of the ...

Embodiment 3

[0091] In Embodiment 3, a device structure that only realizes cutting and clamping is provided.

[0092] The difference between embodiment 3 and embodiment 1 is that the guide rail 1, the guide rail slide table 2, and the No. 1 cylinder 5 are removed, the mounting plate 3 and the clamping support plate 14 are kept, and the bearing assembly and the No. 2 cylinder assembly are directly installed on the mounting plate 3. On, cut off and clamp support plate 14, cut off plate 15, cut off clamping plate 16, clamping plate 17 are installed in the shaft end of rotating shaft in the clamping assembly, and are locked by bolt 20, spring 21 and nut 22.

[0093] in working:

[0094] 1. First, use the No. 2 cylinder device 12 to drive the rotation shaft 8 to rotate through the fish-eye connector 11, the connecting rod 10, and the fixing ring 9, and drive the rotation of the cutting clamping plate 16 to make the gap of the cutting clamping plate 16 and the cutting clamping support Plate 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com