Label printer and label accurate positioning printing method thereof

A printer and label technology, applied in typewriters, printing devices, printing, etc., can solve the problems of inconvenience, high cost, and large space, and achieve the effects of avoiding wrinkling, avoiding waste, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

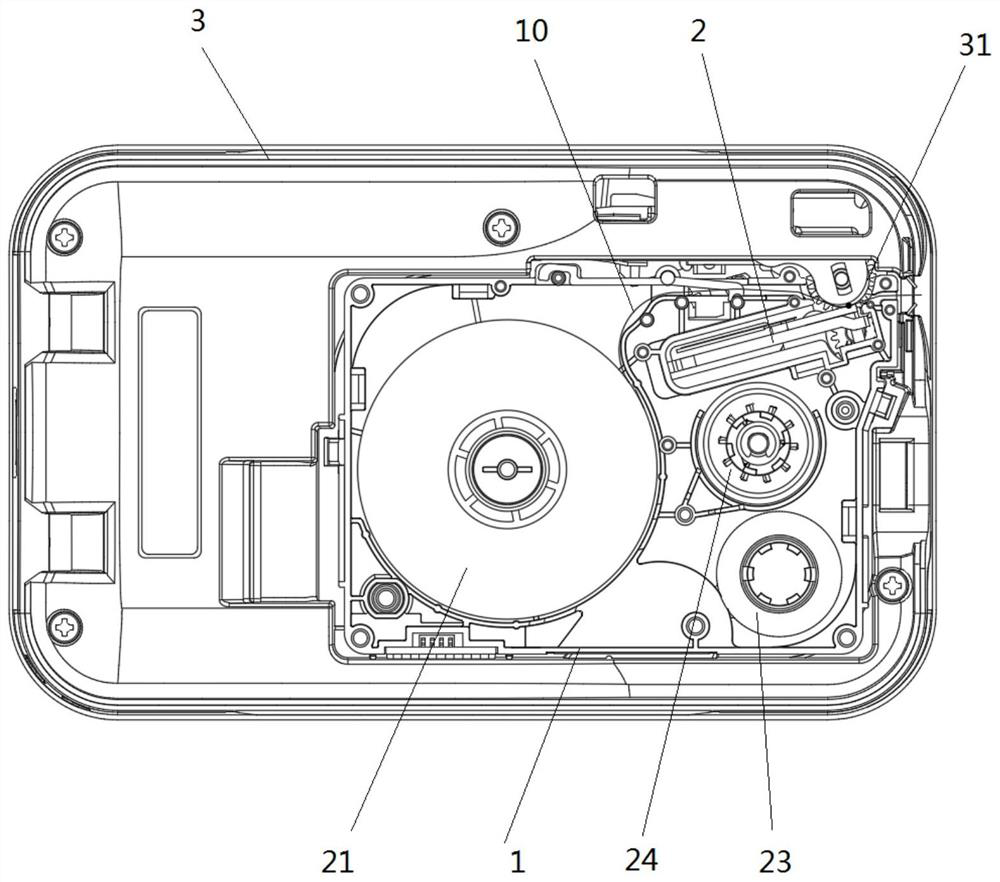

[0046] Refer to attached figure 1 As shown, the label printer of this embodiment includes an outer casing 3 and a label box 1 installed inside the outer casing 3, and a power mechanism and a control mechanism for controlling the output of the label box and the retraction of the carbon ribbon. Print head 2 for label printing.

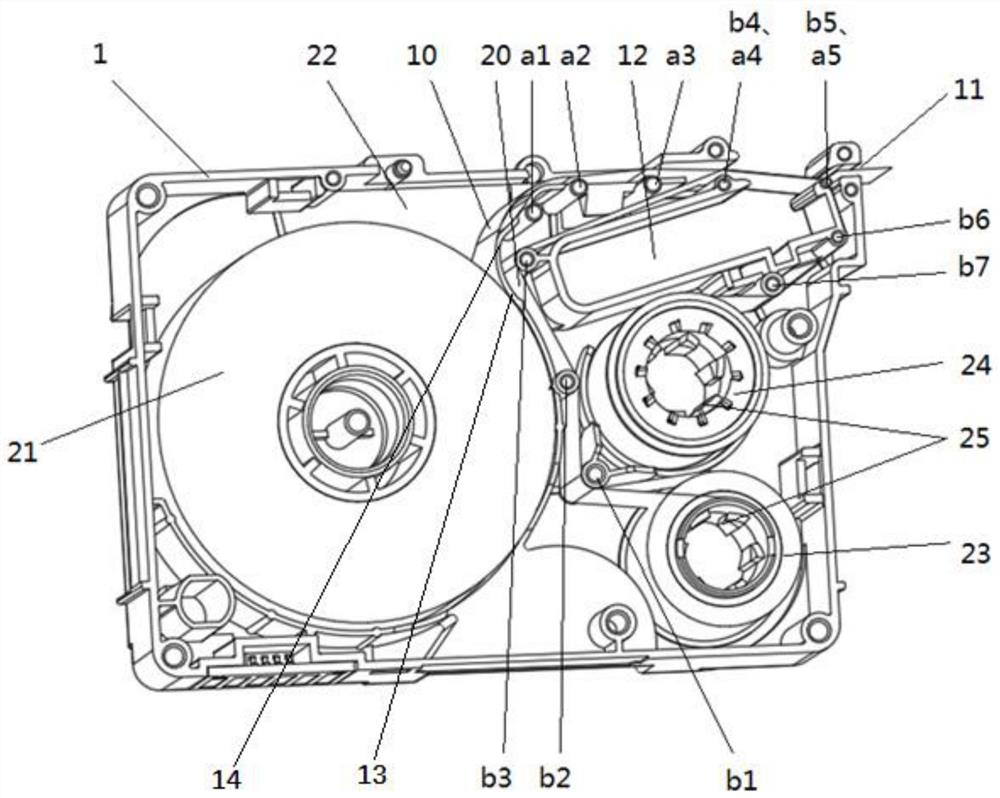

[0047] Specifically, refer to the attached figure 2 As shown, the label cassette 1 in this embodiment includes a housing and a label paper output passage and a ribbon passage arranged inside the housing. The label paper outlet channel is arranged in a nearly straight line corresponding to the paper outlet 11 of the housing, and a groove 12 for placing the print head 2 is also provided inside the housing, and the opening end of the groove 12 is set close to the paper outlet 11 , the carbon ribbon channel is arranged around the groove 12, and the carbon ribbon 20 at the opening end of the groove is in close contact with the label paper 10, which is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com