Method for attaching carbon-coated copper foil in organic electroluminesence display

An electro-laser, copper foil technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of easy attachment and unevenness, easy existence of air bubbles, lamination deformation of carbon-coated copper foil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0030] In order to achieve the purpose of the present invention, in some embodiments of the present invention, a method for attaching carbon-coated copper foil in an organic electric laser display:

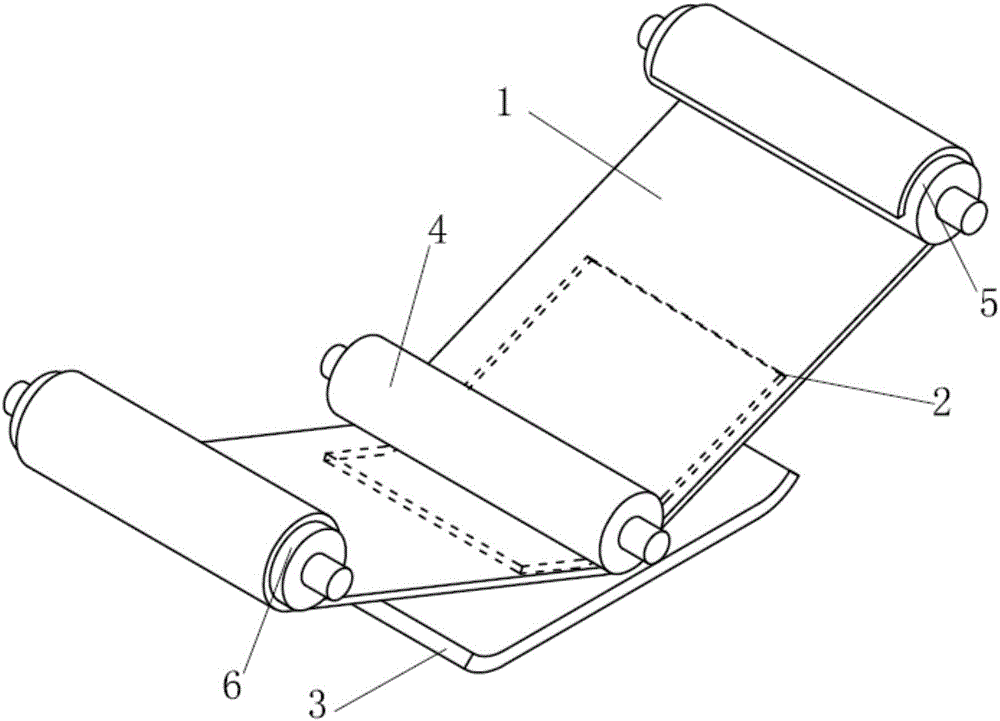

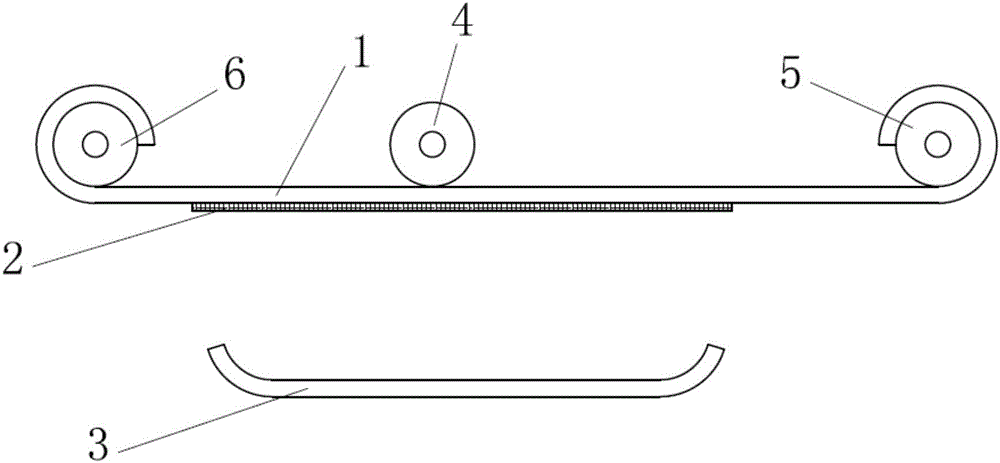

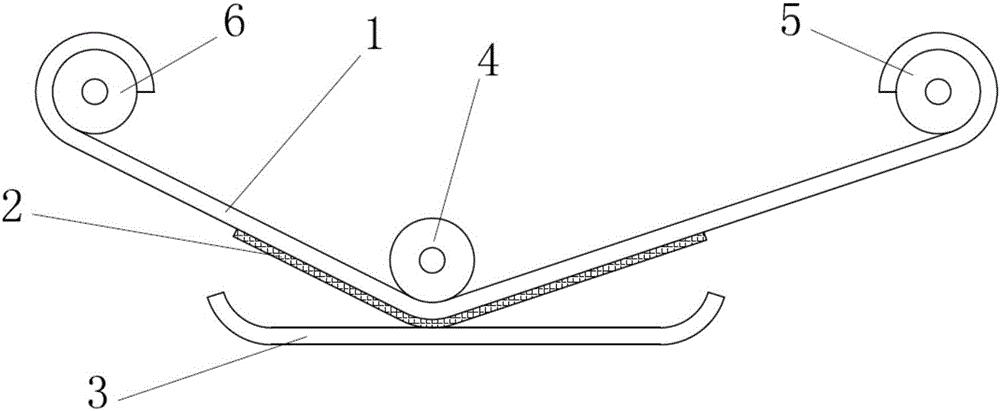

[0031] figure 2 It shows a front view of the pressing roller in an unpressed state in one embodiment of the present invention. The intermediate belt 1 is connected between the first roller 5 and the second roller 6, and the intermediate belt 1 can move along the left and right direction in the figure as the first roller 5 or the second roller 6 is wound. The lower surface is attached to the upper surface of the carbon-coated copper foil 2, the middle belt 1 and the carbon-coated copper foil 2 are in a natural and straight state, and the sticking plate 3 is fixed below the carbon-coated copper foil 2 with a certain distance between them. Since the carbon-coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com