Rope feeding device

A rope-pressing device and rope-feeding technology is applied in the direction of a hoisting device, a spring mechanism, etc., which can solve problems such as clutter of cables and achieve the effect of preventing clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

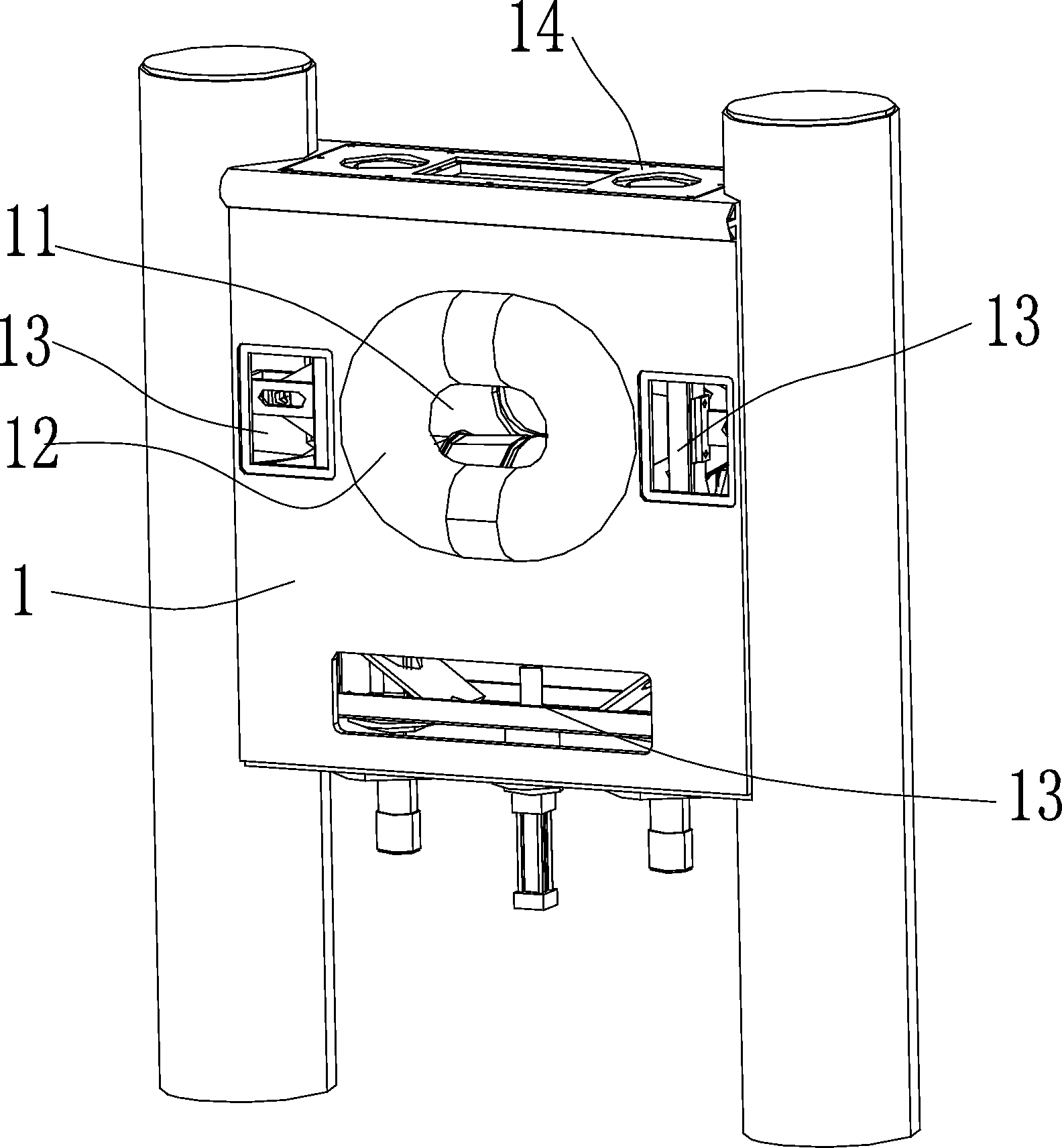

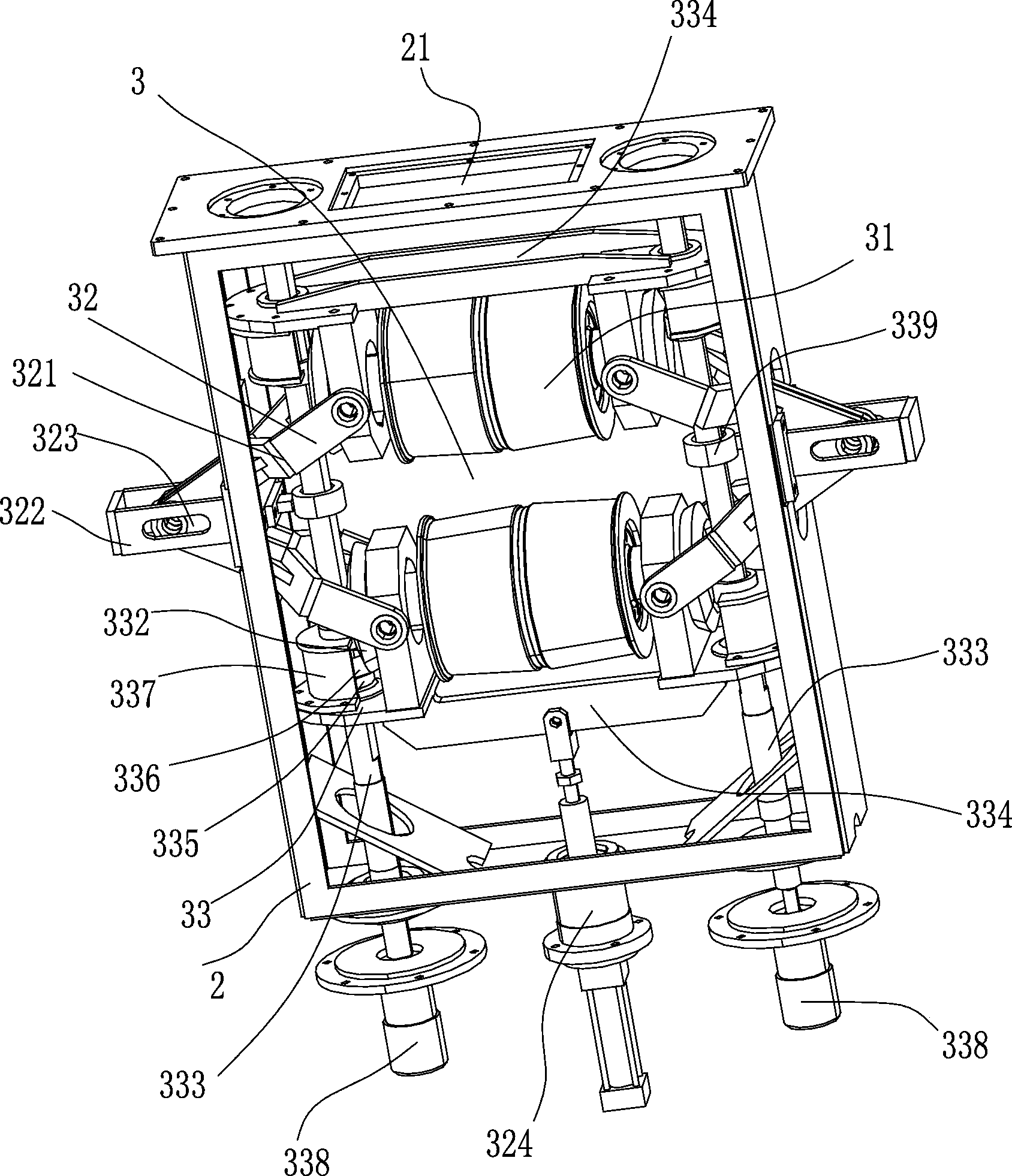

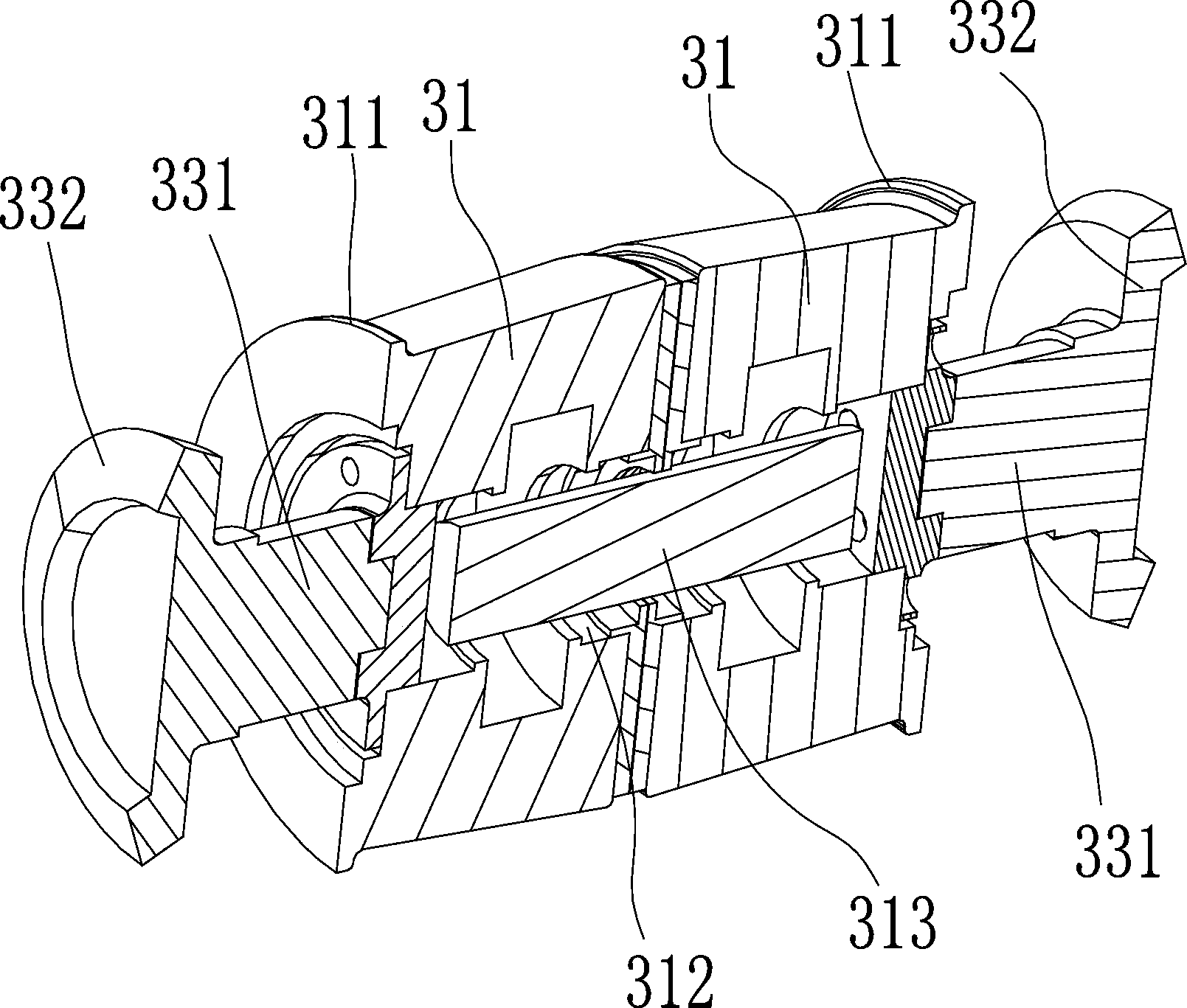

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments: see Figure 1 to Figure 5 , A rope feeding device, comprising a housing 1, a bracket 2 is arranged in the housing 1, and a rope hole 11 is arranged on the housing 1. In order to increase the service life, both ends of the rope hole 11 are A wear-resistant protective sleeve 12 is provided. The side of the protective sleeve 12 close to the rope hole 11 is in a circular arc transition. The original rope hole 11 is generally rectangular, and the cable usually leans against the tip of the rope hole 11 when passing through. At the corners, the local stress at the sharp corners is relatively large and easily damaged. The rope-pressing device 3 is provided in the rope through hole 11, and the rope-pressing device 3 includes two rollers 31 that cooperate with each other to compress the driving structure 32. , The drum rotation drive structure 33.

[0018] The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com