Drilling machine with supporting frame

A support frame and drilling machine technology, which is applied in the field of drilling machines, can solve the problems of difficult to control the fixing of the drilling machine, and the fixing is not firm, so as to achieve the effect of firm fixing and avoiding gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

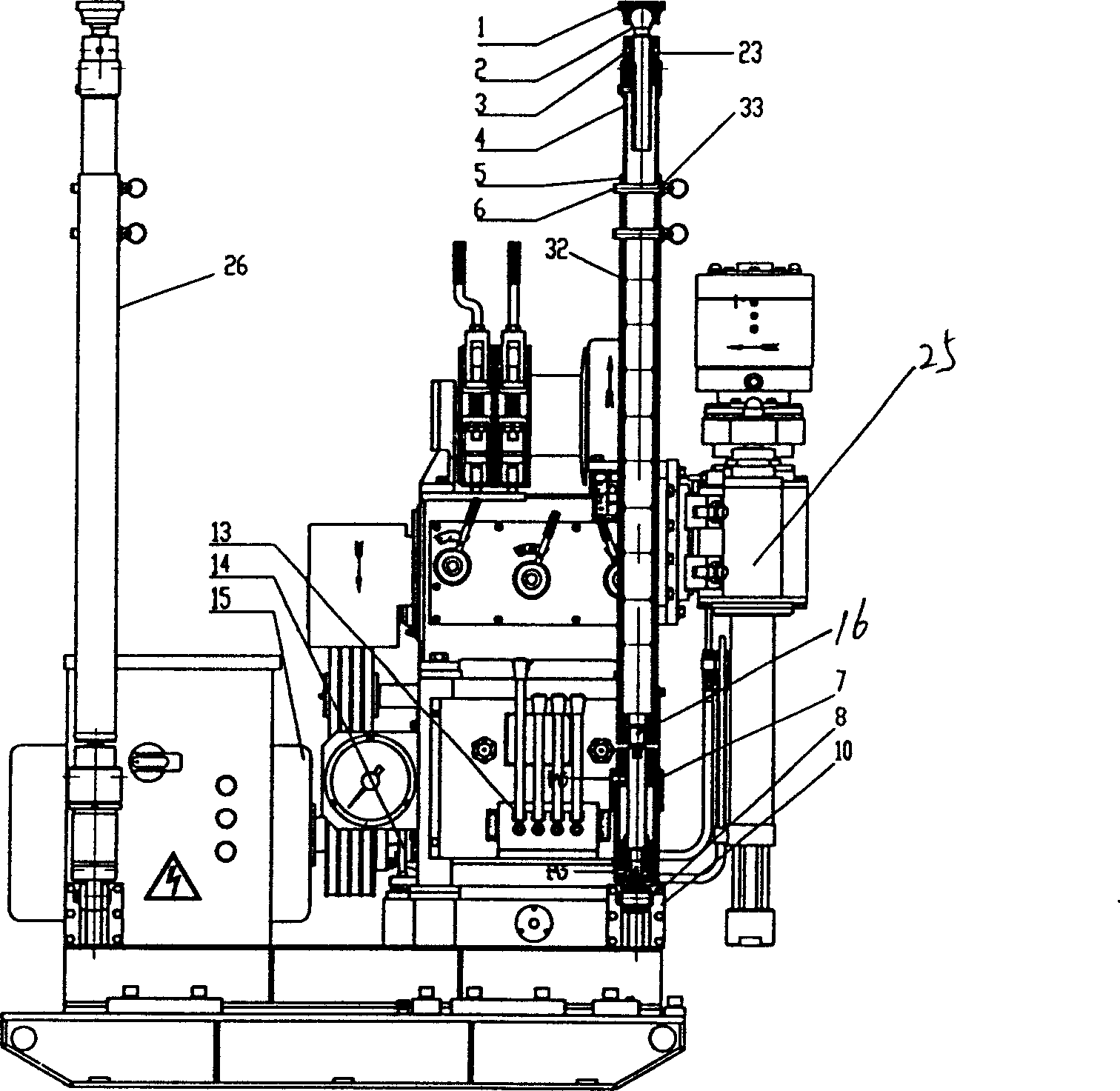

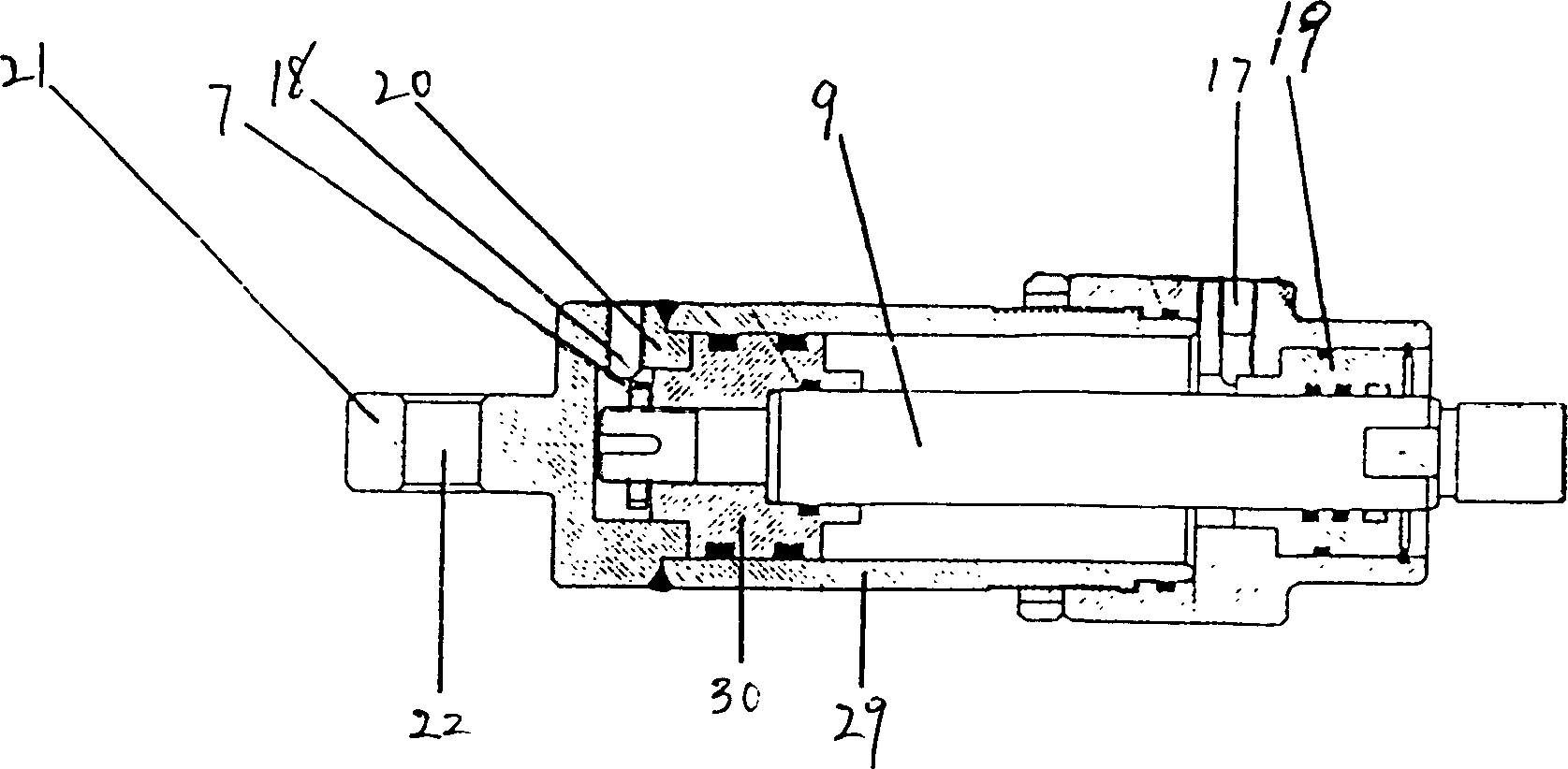

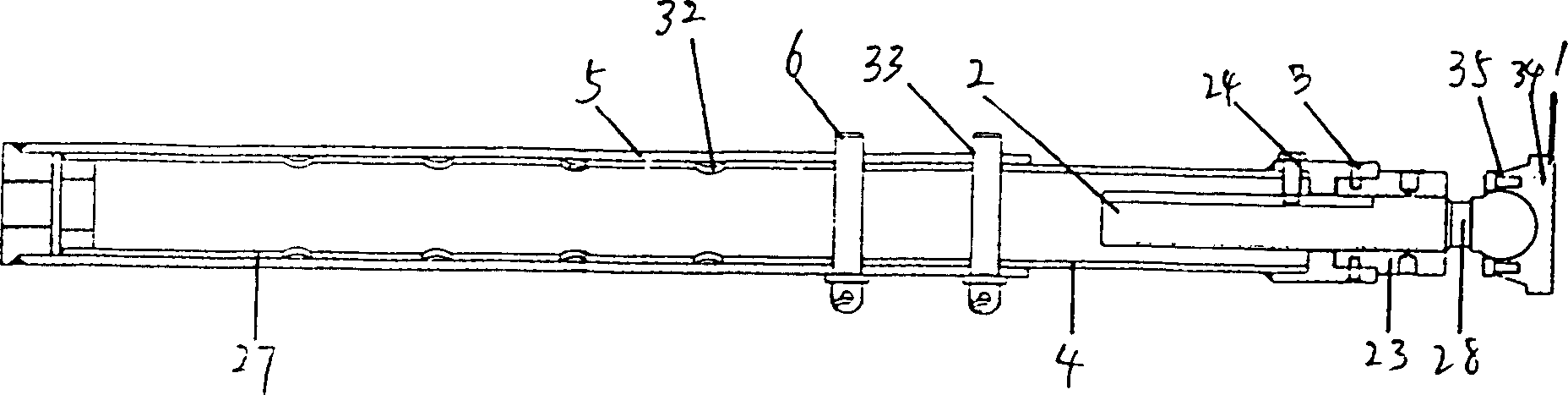

[0014] Such as Figures 1 to 3 As shown, the present embodiment is made up of body 25, motor 15, oil pump 14, control valve 13, support frame 26, wherein, motor 15, oil pump 14, control valve 13 are arranged on the body 25, support frame 26 is formed by hinge support 10 , support cylinder 7, strut 27 and fine-tuning device 28, hinge support 10 is arranged on the body 25, and is fixed with screw, and support cylinder 7 is made up of cylinder body 29, piston 30, piston screw rod 9, oil cylinder upper cover 19 and oil cylinder Bottom cover 20 is formed, and support oil cylinder 7 is fixedly connected on hinge support 10, and strut 27 is made up of inner strut 4 and outer strut 5, and strut 27 is arranged on support oil cylinder 7, and fine-tuning device 28 is composed of adjusting sleeve 23, Adjusting screw mandrel 2, ball hinge cover 34 and hinge cover nut 35 form, and ball hinge cover 34 and hinge cover nut 35 constitute hinge ball seat 1, fine-tuning device 28 is arranged on s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com