Device for calibration of metal rockwell hardness tester indentation depth measurement systems

A technology of Rockwell hardness tester and indentation depth, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of fast displacement speed, small transmission ratio, and difficult to achieve displacement control, so as to achieve convenient operation and ensure synchronization performance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

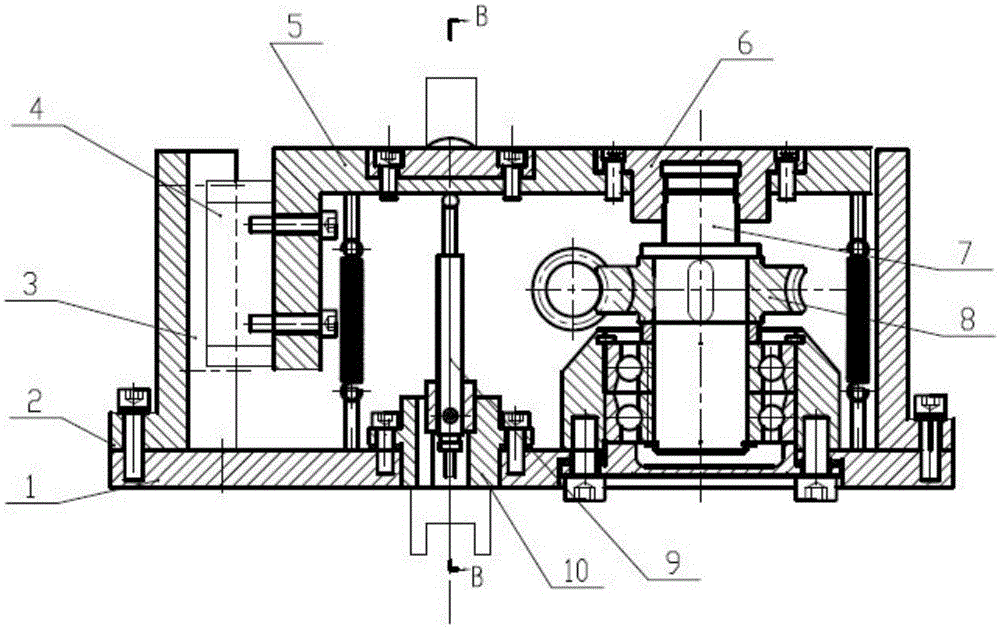

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

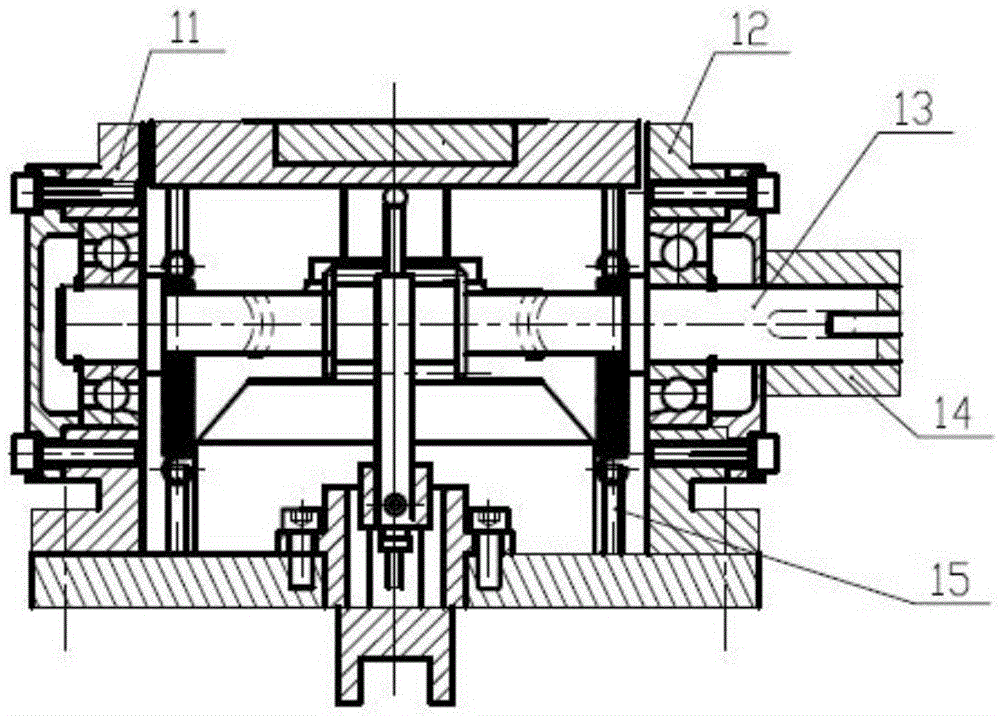

[0023] see figure 1 , the present invention includes a base 1, one end of the base 1 is vertically provided with a left end plate 2, a linear guide rail 3 is arranged on the left end plate 2, and the linear guide rail 3 is fixed on the left end plate 2 by bolts, and a slider 4 is arranged inside the linear guide rail 3 , the linear guide rail 3 is matched with the slider 4 without clearance, the slider 4 is set on the moving plate 5, and the slider 4 is connected with the moving plate 5 through bolts, and the moving plate 5 is also provided with a transmission for moving the moving plate 5 up and down system, the transmission system includes a worm 13, a turbine 8 and a screw arranged on the turbine 8; a guide sleeve 6 is also arranged on the moving plate 5, and a screw 7 is arranged inside the guide sleeve 6, and one end of the screw rod 7 and the guide sleeve 6 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com