Novel mechanical paraffin cleaning hoist applied to petroleum field

A new type of technology, applied in the field of new mechanical wax cleaning winches, can solve the problems of backward overload safety protection devices, low automation and complex structure of the winch, and achieve the effects of compact structure, stable transmission and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

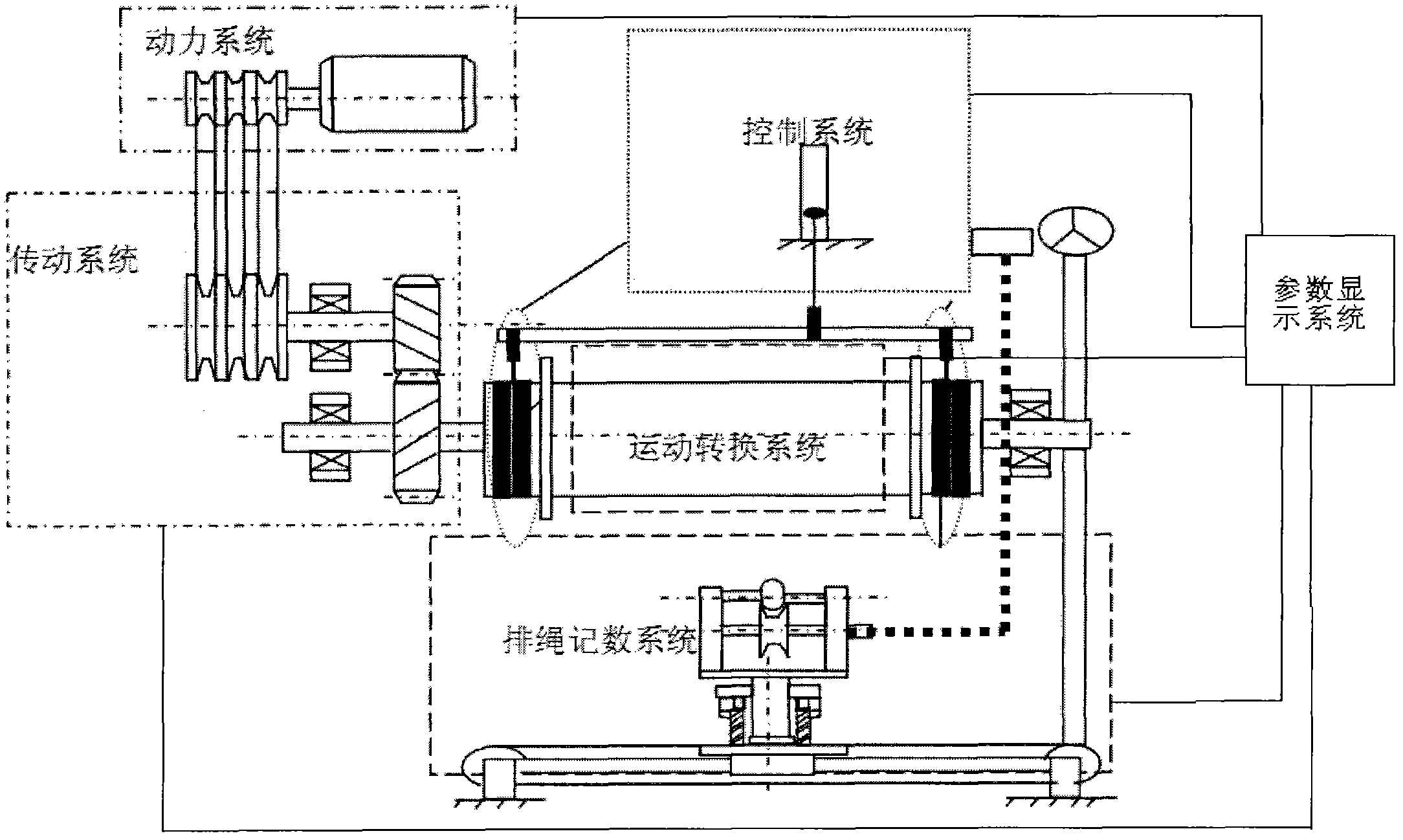

[0046] This embodiment relates to a new type of mechanical wax removal winch used in the petroleum field. It is mainly composed of a power system, a transmission system, a motion conversion system, and a rope counting system connected in sequence. The motion conversion system is connected with a control system. And the power system, transmission system, motion conversion system, rope counting system and control system are all connected with the same parameter display system.

[0047] The power system is mainly composed of an anti-explosion AC motor with stepless speed regulation in forward and reverse directions.

[0048] The transmission system is mainly composed of a belt transmission and a gear transmission with two stages of variable speed transmission.

[0049] The motion conversion system is mainly composed of a drum and a wire rope.

[0050] The control system is mainly composed of a set of clutch, belt hub brake and hand brake.

[0051] The rope counting system is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com