Large-current intelligent digital welding system verification and calibration method

A welding system and high current technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as inaccurate measurement, abnormal welding machine and inability to make correct evaluation of the integrity, and achieve the effect of guaranteeing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

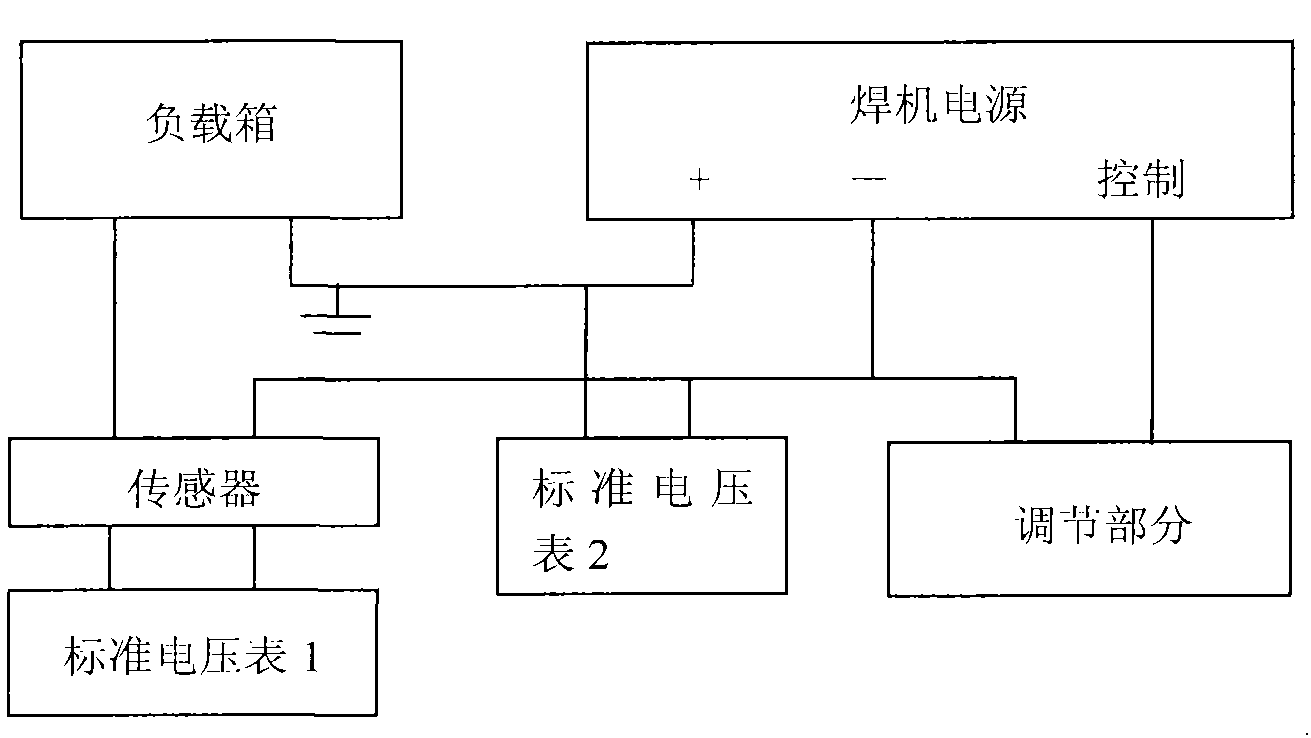

[0014] according to figure 1 Connect the load box, the shunt current terminal and the output terminal of the welding power supply of the welding system together end to end in series to form a loop. Connect the standard voltmeter 1 (digital multimeter) to both ends of the sensor voltage, and the standard voltmeter 2 (digital multimeter) ) and connected to the two output terminals of the welding power supply, the welding power supply and the adjustment part are connected together with a special line to form a control circuit, and the load box is set at the rated current value of the welding system under test.

[0015] 1. Power-on inspection

[0016] After ensuring that the wiring is correct, turn on the power supply of the welding machine, load box, and standard digital multimeter, and visually check whether the display of all equipment is normal.

[0017] 2. Verification / calibration

[0018] Short-circuit the output end of the welding torch connection. If the display of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com