Supercritical water oxidation treatment and generation system of municipal sludge having high-solid content

A supercritical water oxidation and municipal sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problems of high operating cost, device shutdown, low solubility of inorganic salts, etc. Achieve reliable continuous operation, reduce operating costs, and overcome corrosion and clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

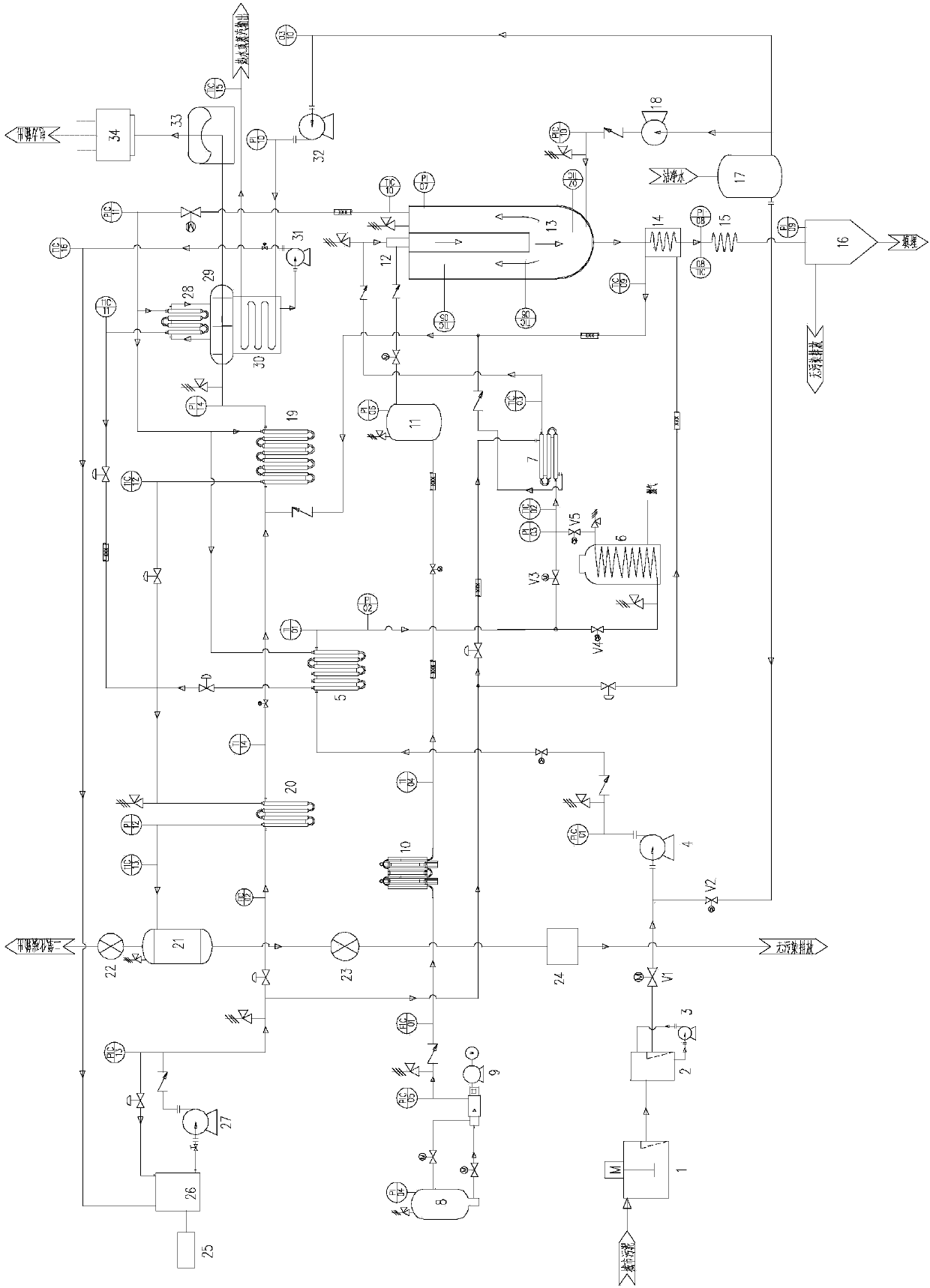

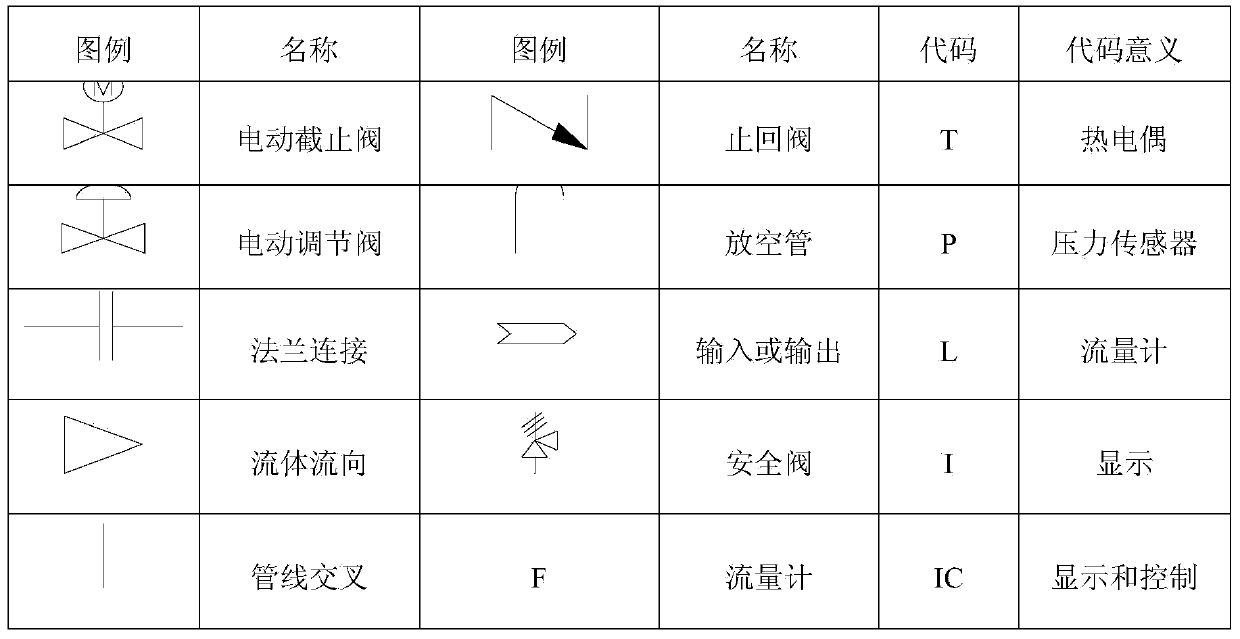

[0022] refer to figure 1 , the supercritical water oxidation harmless treatment of high solid content urban sludge of the present invention and the connection relationship of the power generation system are as follows:

[0023] 1) The outlet port of crushing and dilution sand settling filter tank 1 is connected to the inlet port of homogenizing tank 2, the outlet port at the bottom of homogenizing tank 2 is connected to the inlet port of sludge homogenizing pump 3, and the outlet port of sludge homogenizing pump 3 is connected to the homogenizing tank 2 The upper inlet port is connected, the other outlet port of the homogeneous tank 2 is connected with the inlet port of the high-pressure diaphragm pump 4, the outlet port of the high-pressure diaphragm pump 4 is connected with the inlet port of the shell side of the first heat exchanger 5, and the shell side of the first heat exchanger 5 is connected The outlet end communicates with the inlet end of the gas furnace 6, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com