System for monitoring transforming plant DC

A DC monitoring and substation technology, applied in general control systems, control/regulation systems, non-electrical signal transmission systems, etc., can solve problems such as heavy tasks, unreachable data, data transmission delays, etc., to reduce the burden and reduce equipment replacement. , the effect of improving openness and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

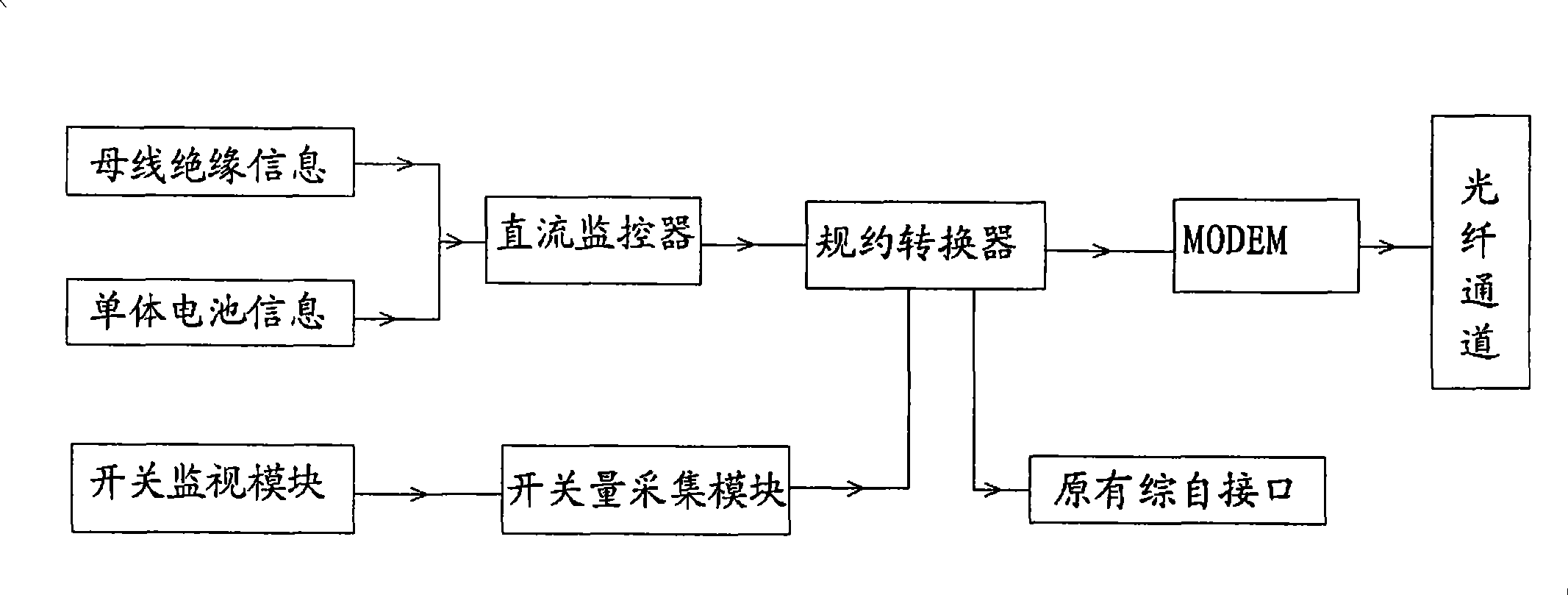

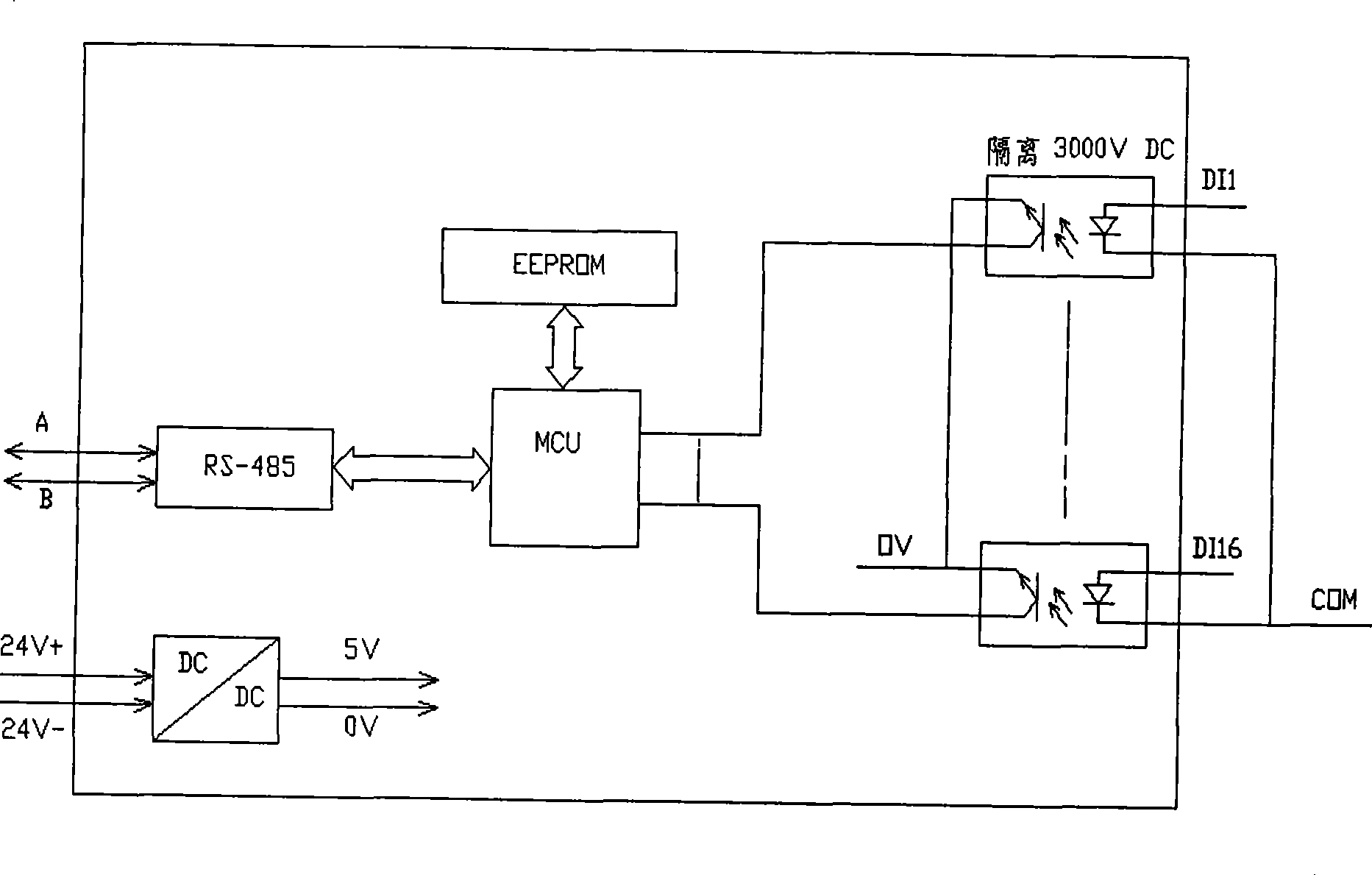

[0016] During specific implementation, the present invention includes remote measurement and control unit (RTU), fiber channel input unit, fiber channel, server, workstation and client computer; Fiber channel input unit is connected with remote measurement and control unit and fiber channel respectively, server, workstation and The client computers are respectively connected to the fiber channel; the connection and related system software presets can refer to the existing data acquisition and monitoring control system (SCADA system).

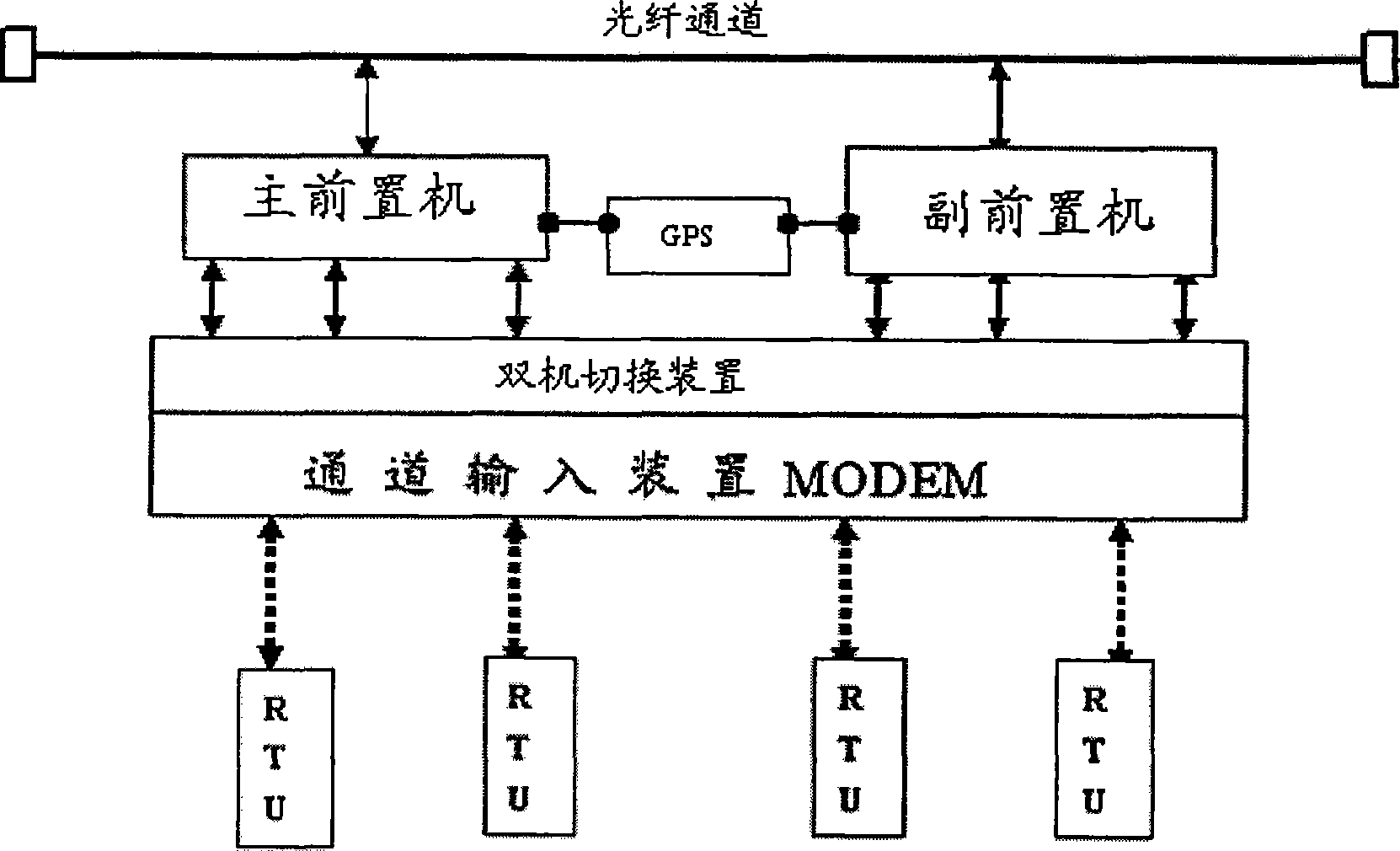

[0017] Such as figure 1 As shown, the front-end processor of the present invention is arranged between the fiber channel input device MODEM and the fiber channel. The dual-computer switching device is connected to the fiber channel input unit, the main front-end processor and the auxiliary front-end processor are connected to the dual-computer switching device, and the communication method between the main front-end processor and the auxiliary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com