Screw fastening device achieving automatic feeding and control manner thereof

A control method and automatic feeding technology, used in metal processing equipment, manufacturing tools, metal processing and other directions, can solve the problems of low production efficiency, high requirements, high labor intensity, etc., and achieve the effect of automatic continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

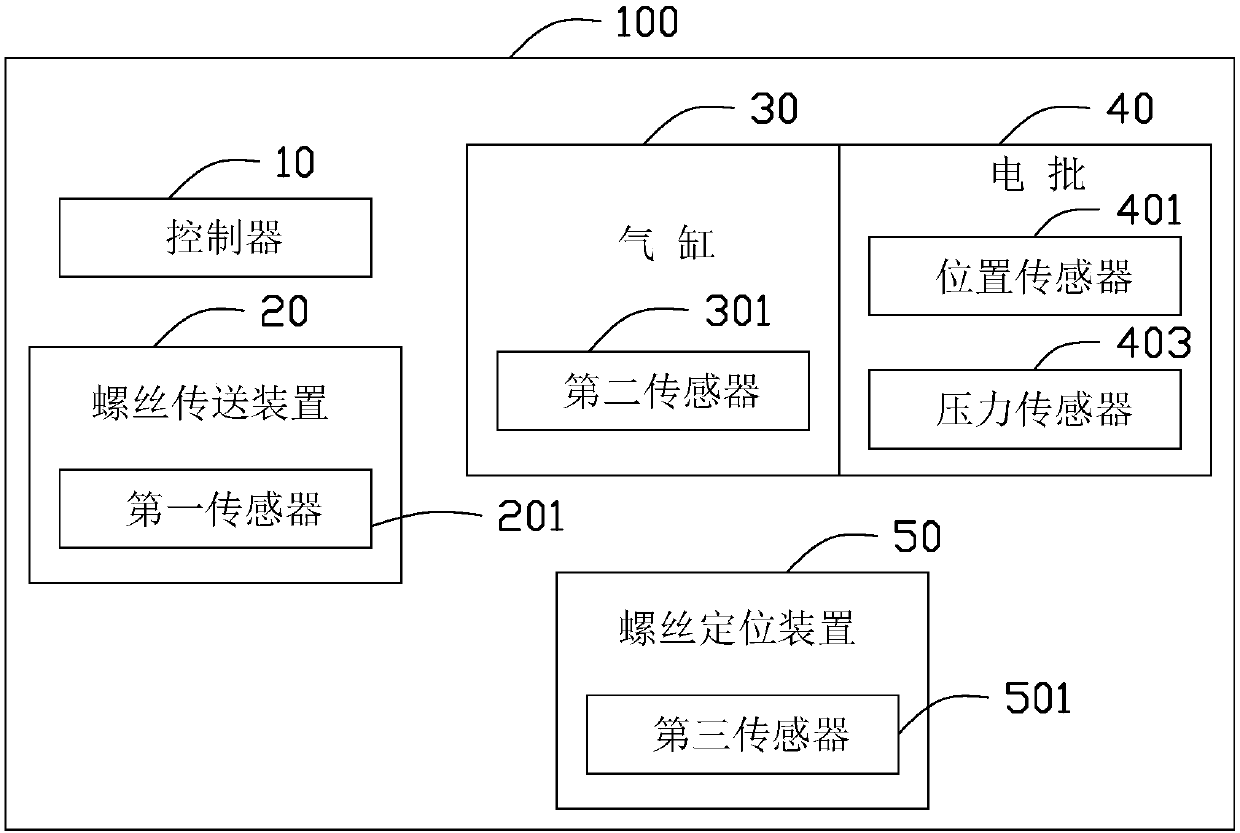

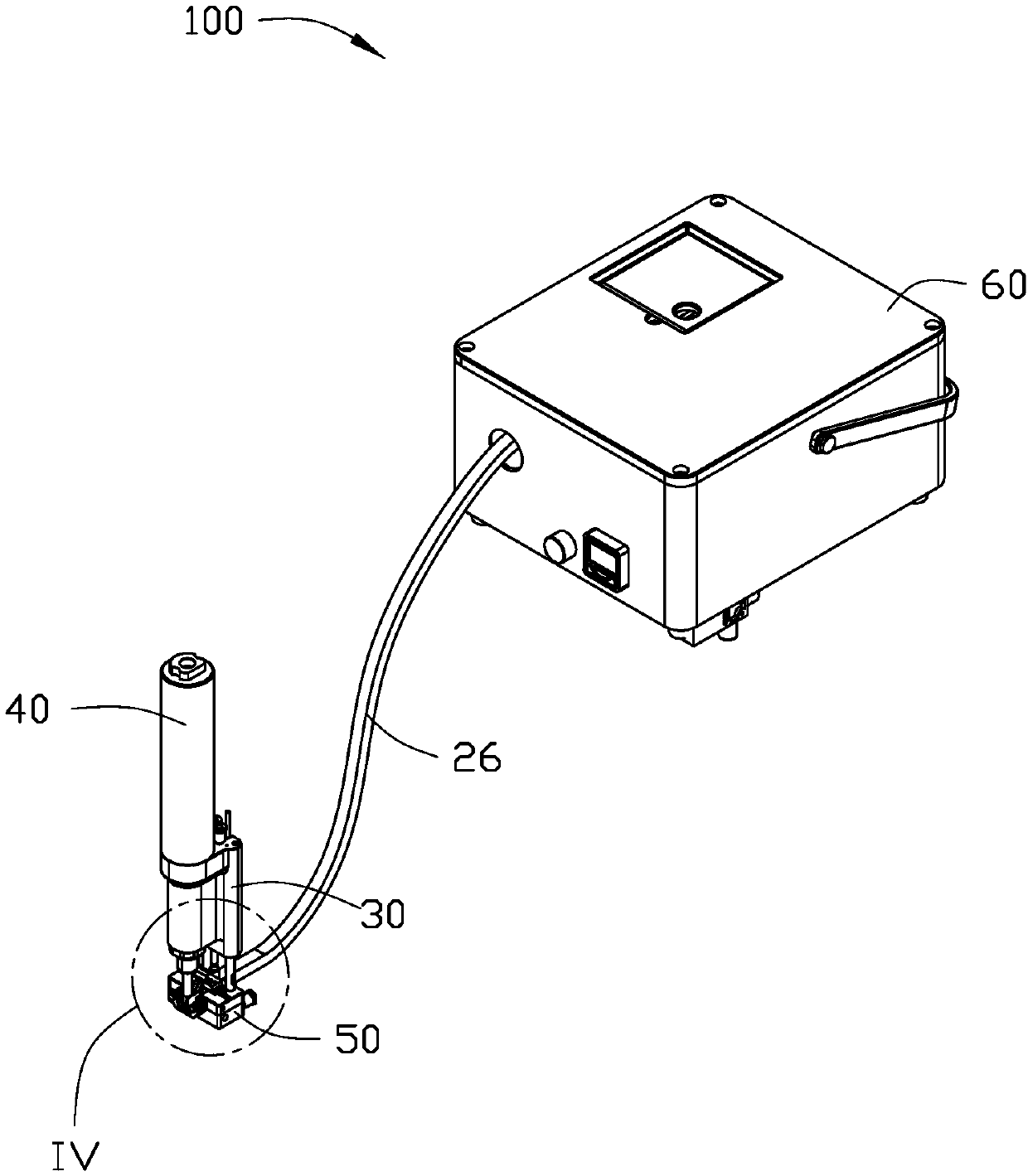

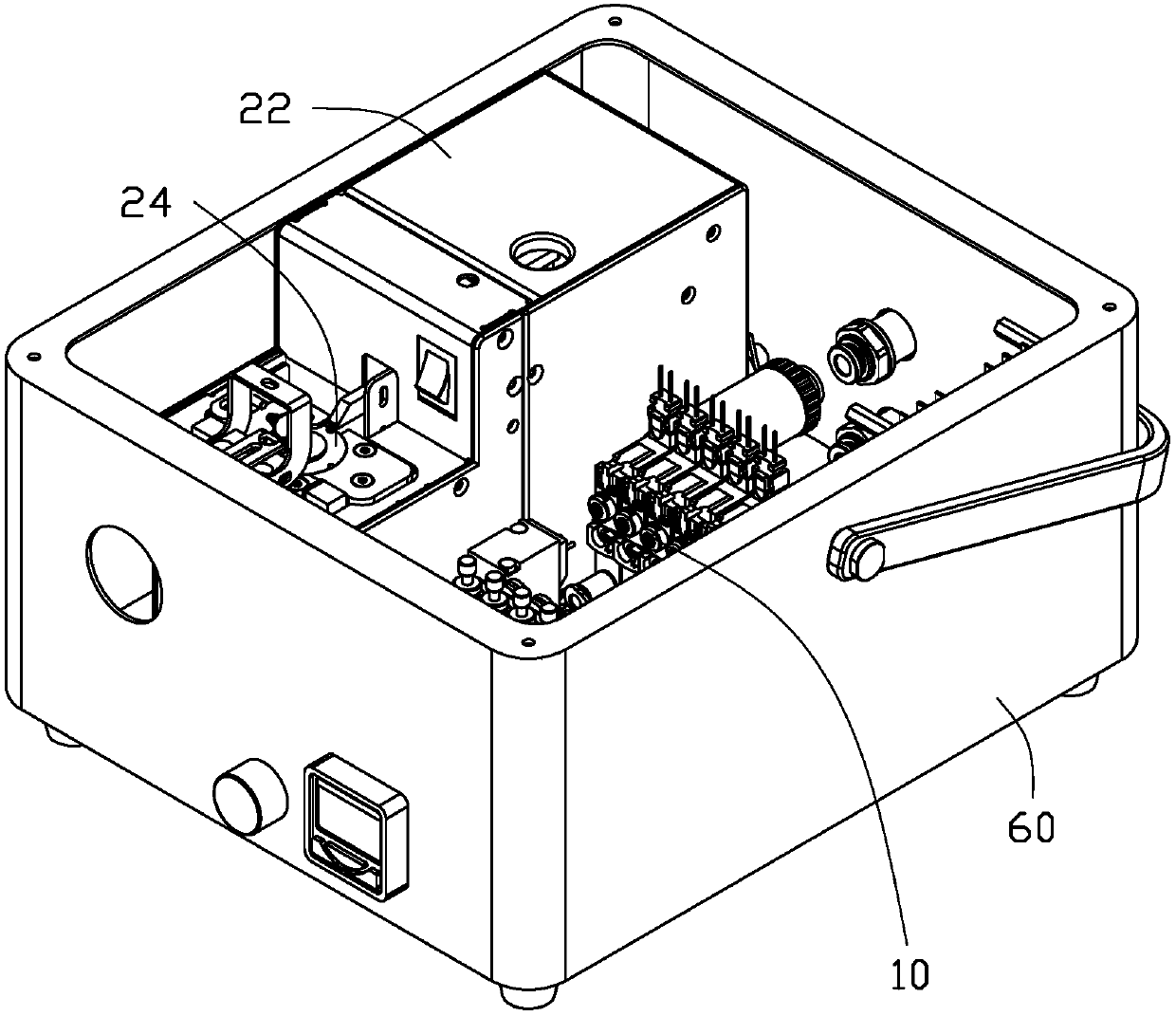

[0029] see figure 1 A block diagram of a screw locking device 100 for automatic feeding. The screw locking device 100 mainly includes a controller 10, a screw transmission device 20, a cylinder 30, and an electric batch 40 arranged on the side of the cylinder 30. When the cylinder 30 goes up, it can Expose electric batch 40. The control mode of the screw locking device 100 includes as follows:

[0030] A first sensor 201 is set on the screw conveying device 20 for sensing whether there is screw conveying;

[0031] If the first sensor 201 judges that the screw transmission device 20 has screw transmission, the controller 10 sends a control signal to control the electric screwdriver 40 to take the screw;

[0032] A second sensor 301 is provided on the cylinder 30 for sensing whether the electric screwdriver 40 has sucked the screw;

[0033] If the second sensor 301 judges that the electric screwdriver 40 has sucked the screw, the controller 10 controls the electric screwdrive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com