a composite car

A technology for composite material trucks and frames, applied in the field of material trucks, can solve problems such as unsatisfactory operating environment and safety, low degree of automation of composite material trucks, and too late to lower down, etc., to achieve automatic continuous operation, improve labor intensity, running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

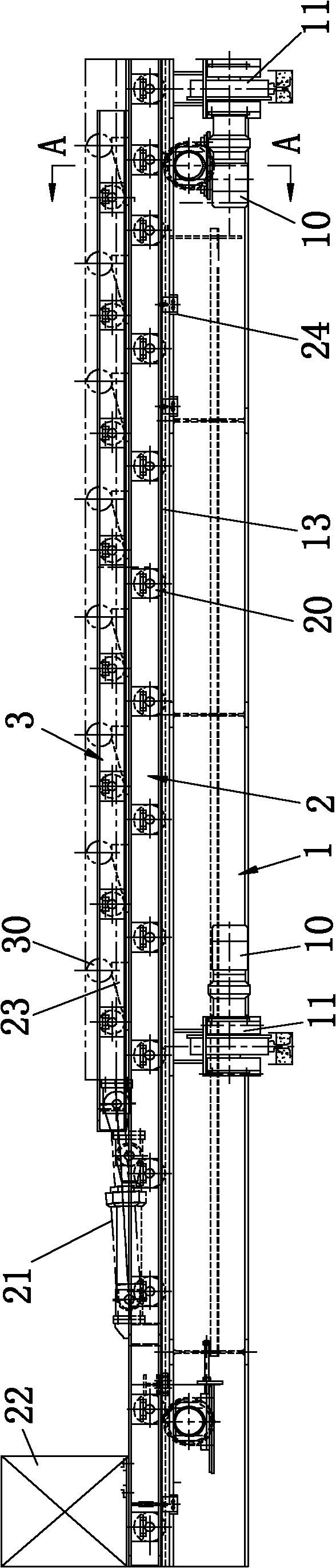

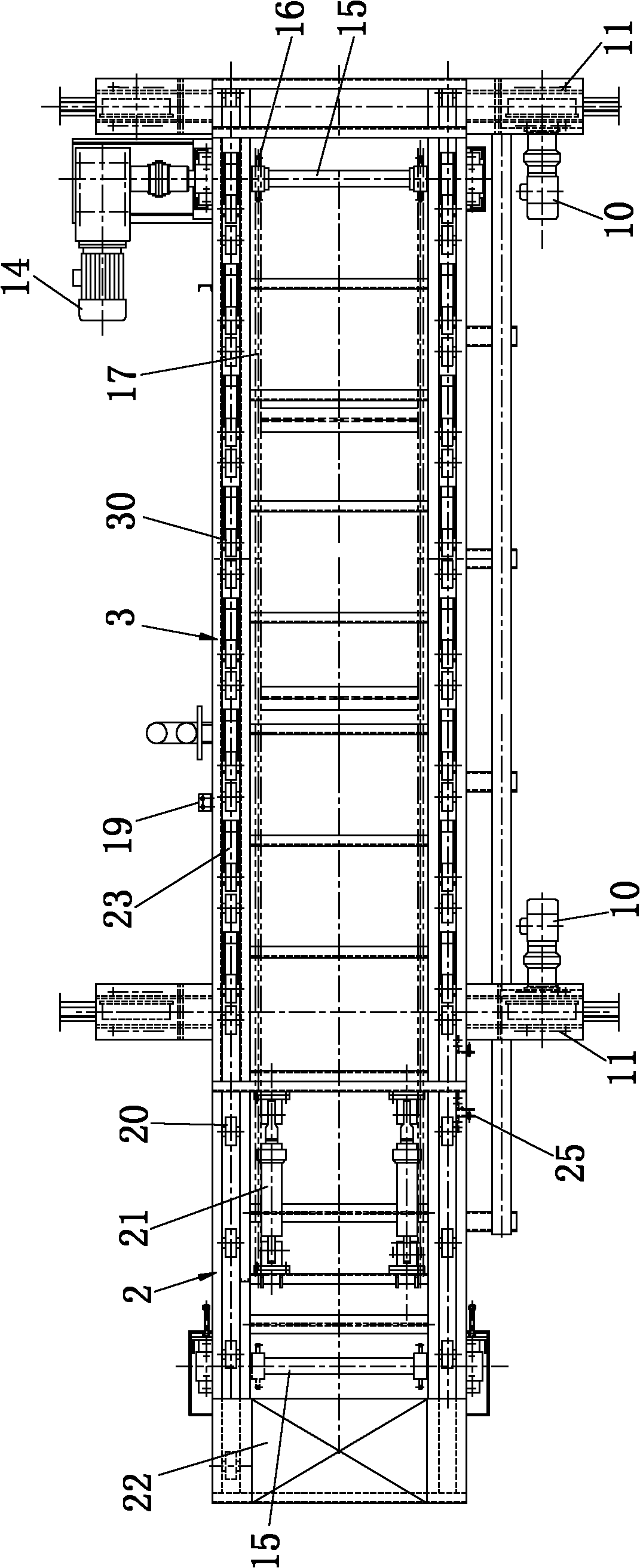

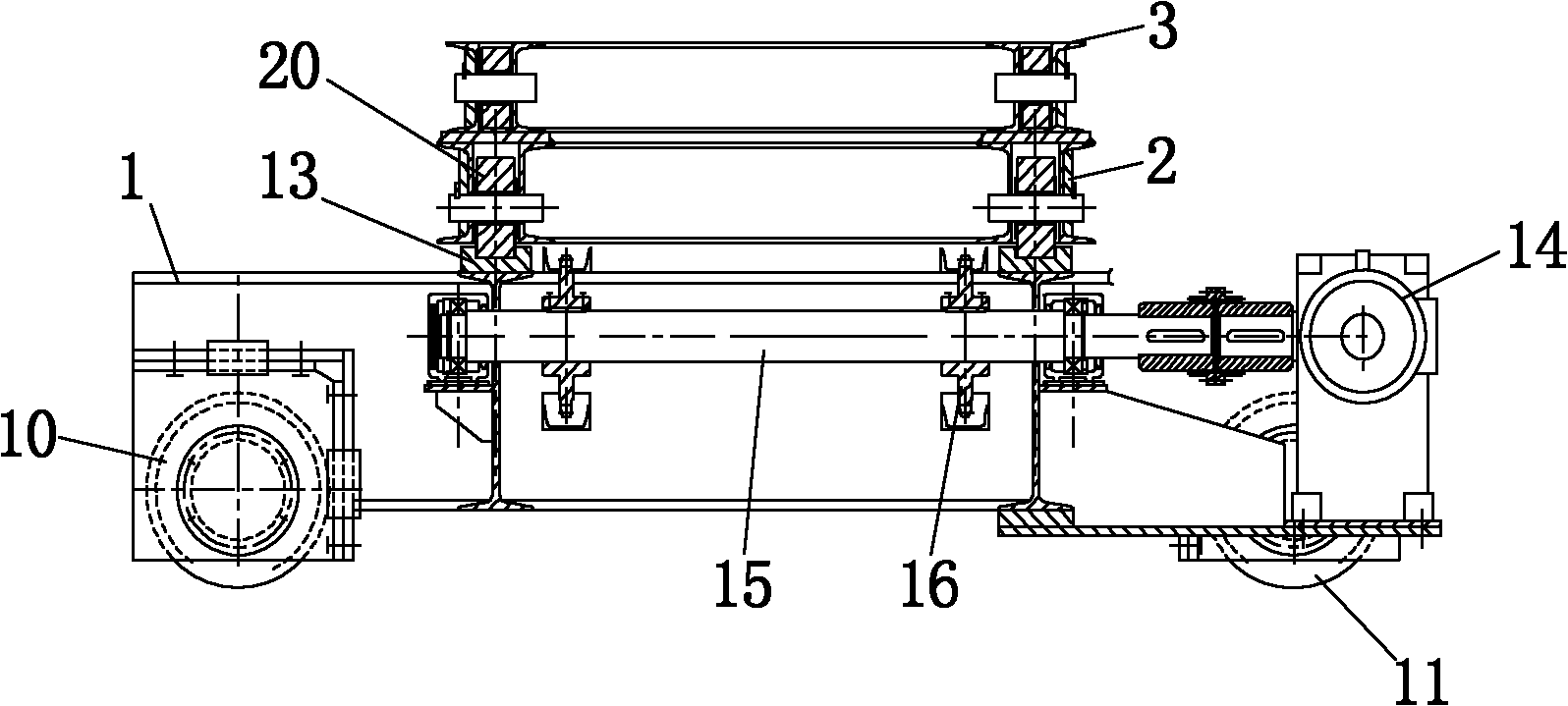

[0016] refer to Figure 1-3 , a composite material car, including a trolley assembly, a middle car assembly, and a cart assembly installed sequentially from top to bottom, and a first drive mechanism for driving the cart assembly to move laterally is installed at the bottom of the cart assembly , There is a second drive mechanism between the cart assembly and the middle car assembly to drive the longitudinal movement of the middle car assembly, and a third drive mechanism is provided on the middle car assembly to drive the longitudinal movement of the trolley assembly. There is a roller guide mechanism between the trolley assembly and the trolley assembly to realize the lifting action while moving longitudinally.

[0017] The cart assembly includes a large frame 1 and large wheels 11 arranged at both ends of the large frame 1; the first drive mechanism is a first reduction motor 10 connected to the large wheel 11; the middle car assembly includes a middle frame 2 And some mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com