Full-automatic tobacco flue-curing house

A kind of flue-cured tobacco room, fully automatic technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of curing effect and quality limitation, curing discontinuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

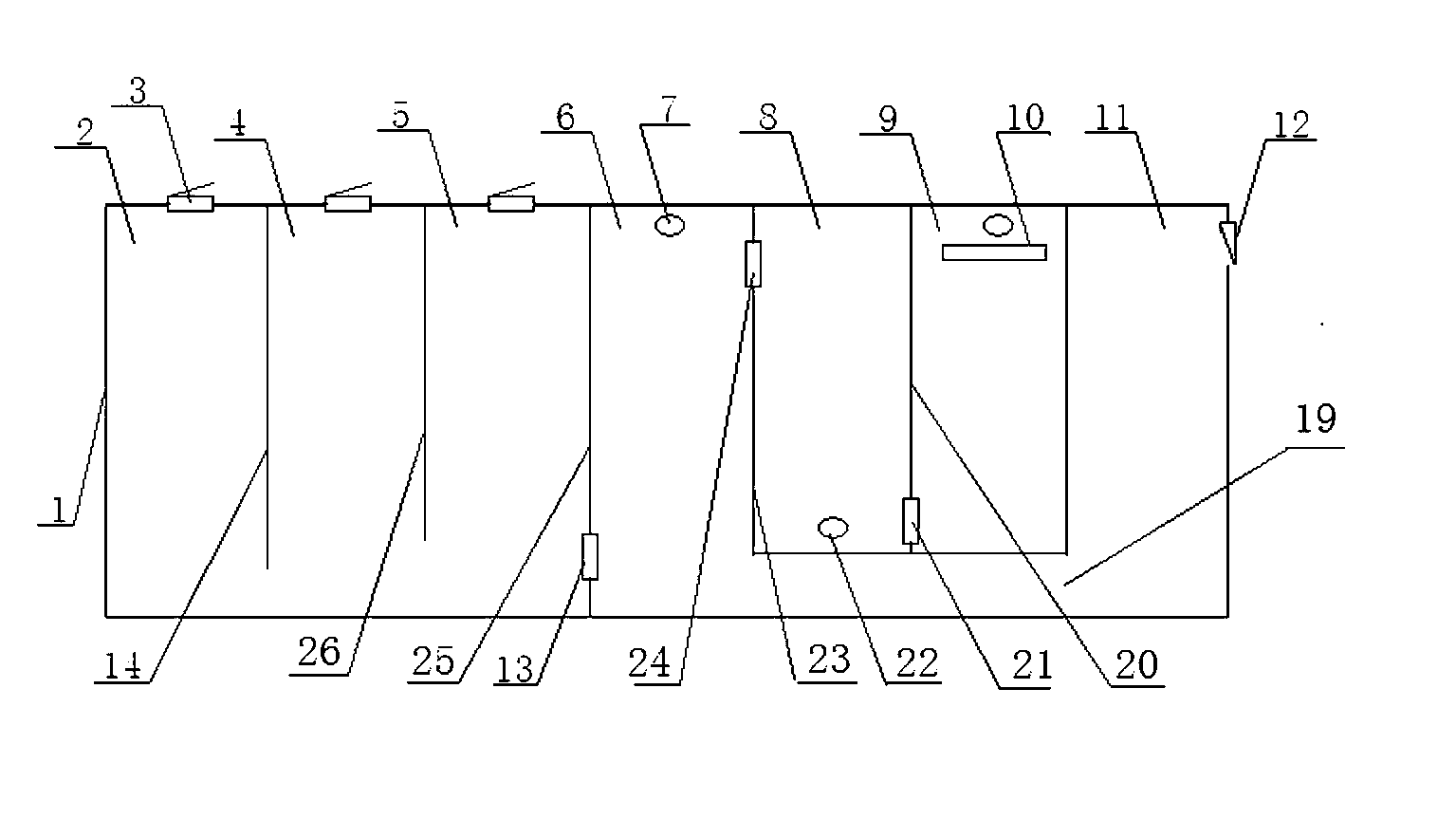

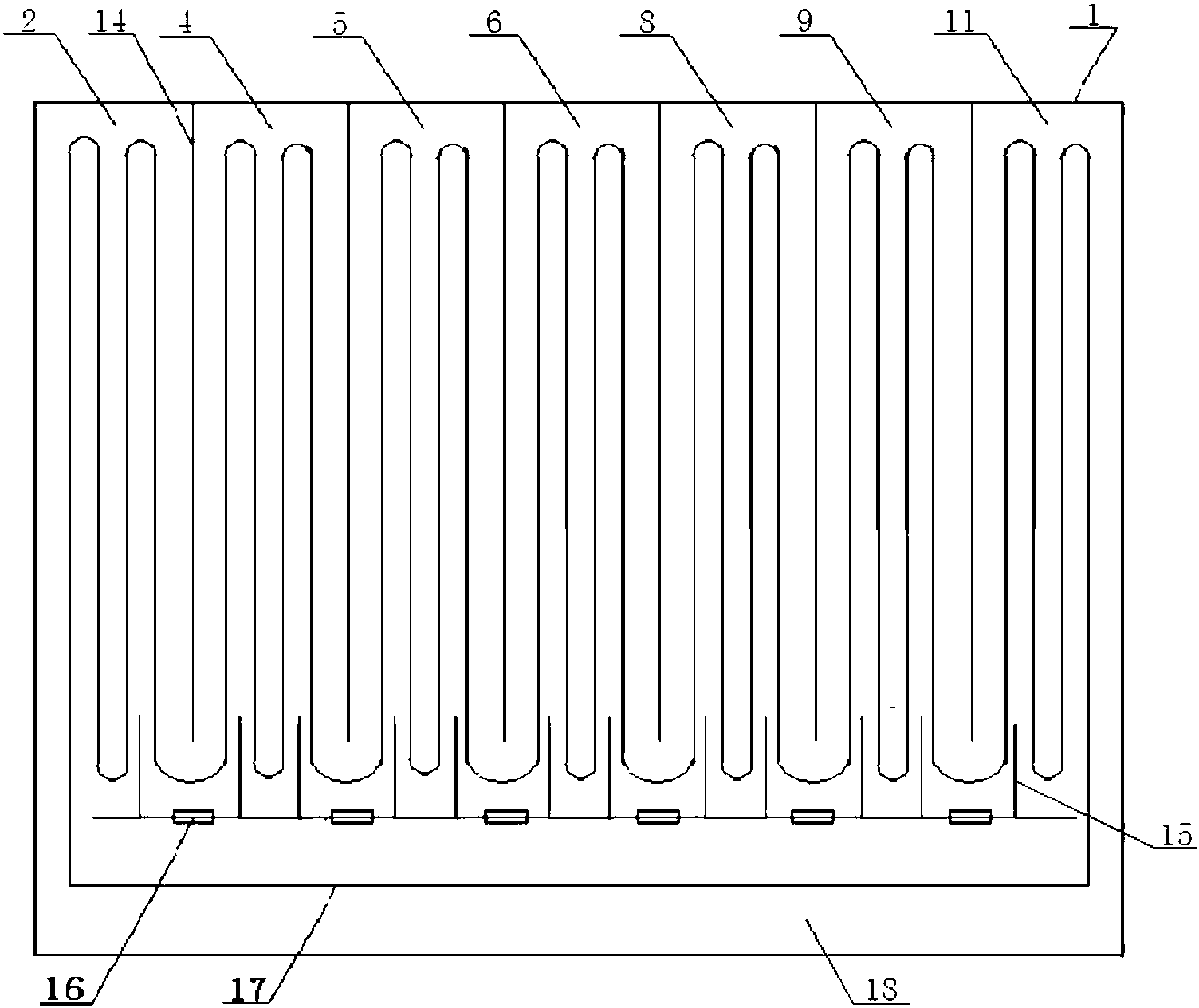

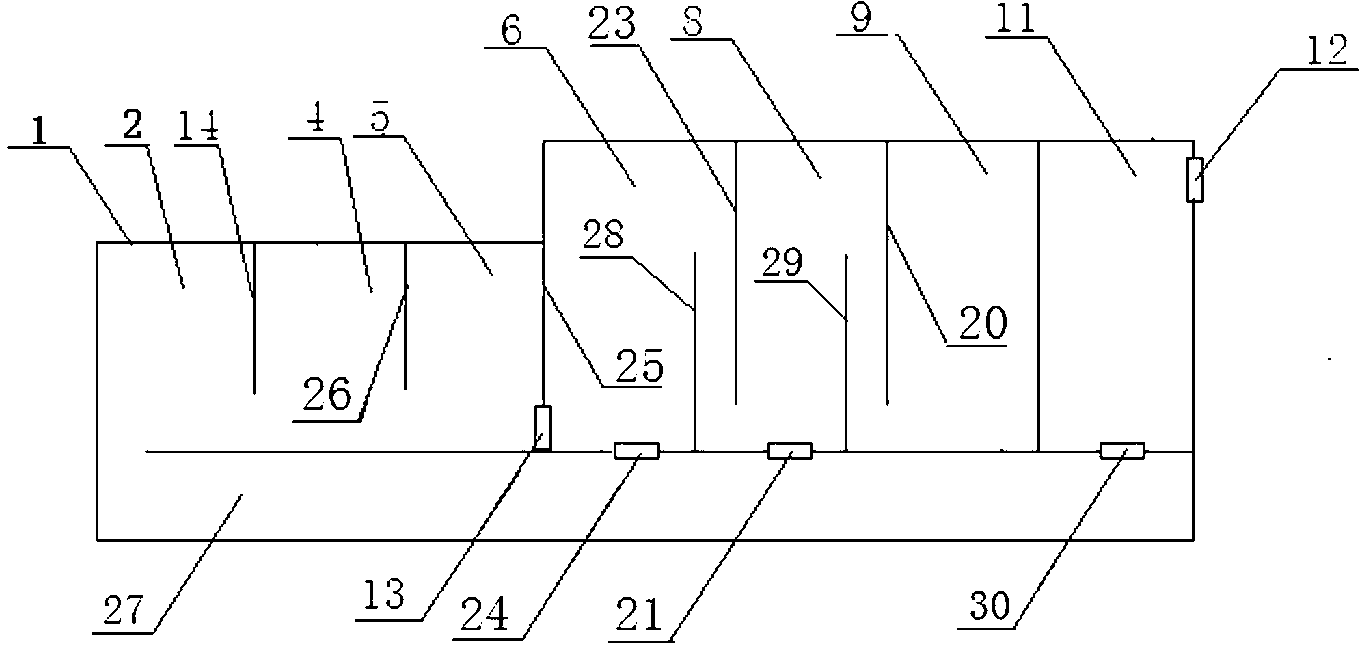

[0020] Such as figure 1 , 2 The fully automatic tobacco flue-curing room shown has a flue-cure room body. The flue-cure room body 1 is placed on a cement foundation. The room material and the internal partition are steel frame structures made of thermal insulation materials, which are tightly connected by fastening parts such as bolts. After loosening the fastening parts, the various parts that make up the flue-cured room can be disassembled, which is convenient for transportation and movement. The roasting area is six roasting areas, according to the order of tobacco leaves entering, they are the first roasting area 2, the second roasting area 4, the third roasting area 5, the fourth roasting area 6, and the fifth roasting area. Zone 8 and the sixth baking zone 9; a heating device 10 is arranged above the sixth baking zone, and a fan blowing hot air downwards is provided above the heating device 10; The hot air circulation channel, the hot air circulation channel includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com