Suspension type high-frequency vibration method and special device

A vibrating device and suspended technology, which is applied in the field of suspended high-frequency vibrating devices, can solve problems such as low flatness, inability to realize automatic continuous operation, and low efficiency, and achieve the goal of improving flatness, realizing automatic continuous operation, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

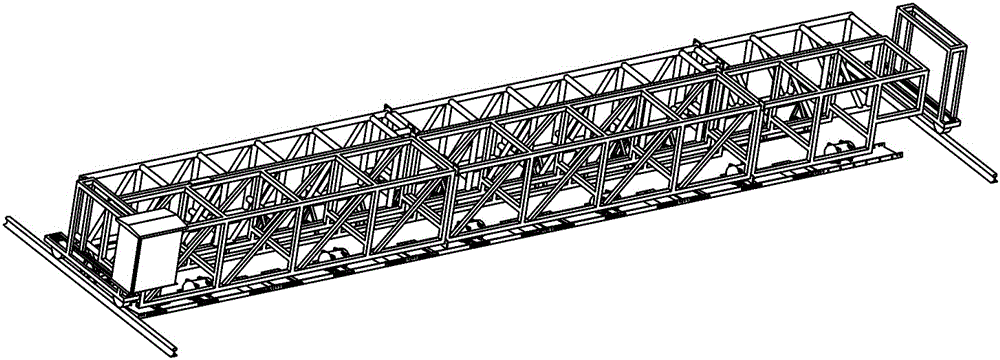

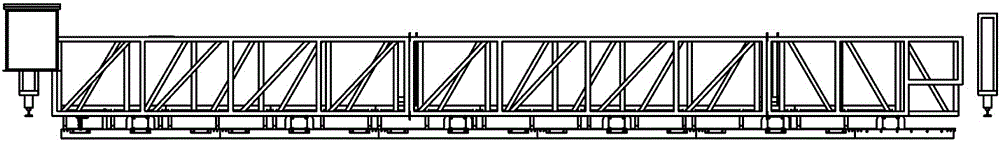

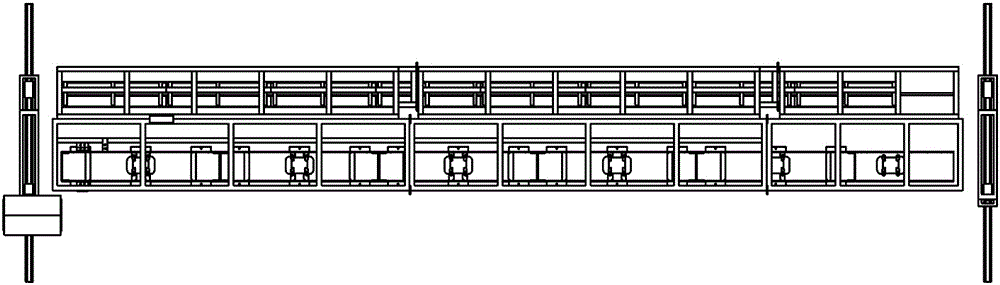

[0028] Embodiment 1, refer to Figure 1 to Figure 5 . The suspended high-frequency vibrating device includes a vibrating truss 25, a vibrating and leveling device 28 and a suspended high-frequency vibrating device 22. The two ends of the vibrating truss 25 are respectively equipped with a vibrating and leveling device 28. Suspended high-frequency vibrating device 22 is installed; said suspended high-frequency vibrating device 22 includes more than 2 vibrating flat plates 222, and high-frequency vibrating motors 221 are respectively installed on each vibrating flat plate 222, and each vibrating flat plate 222 adopts an elastic suspension device 223 is installed under the vibrating truss 25, and each high-frequency vibration motor 221 drives each vibrating plate 222 to vibrate up and down; when the cloth machine finishes laying a preset length of vertical cloth, the vibration leveling intelligent control device instructs to start the suspension type The high-frequency vibrating...

Embodiment 2

[0032] In Embodiment 2, the present invention may also provide a vibration damping device 225 between the elastic suspension device 223 and the vibrating plate 222 , so as to buffer the vibration of the vibrating truss 25 . refer to Figure 1 to Figure 5 , all the other are with embodiment 1.

Embodiment 3

[0033]Embodiment 3, the present invention may also be provided with a vibrating leveling intelligent control device 26 matched with a high-frequency vibration motor 221 on the vibrating truss 25, and the vibrating leveling intelligent control device 26 may also be installed on the vibrating leveling On the leveling walking device 28, in order to reduce the influence of vibration on the leveling intelligent control device 26 due to vibration, preferably the vibration leveling intelligent control device 26 is installed on the vibration leveling leveling device 28, so that Realize automatic control with other systems. For example, after the precision cloth machine finishes laying out the predetermined length of longitudinal cloth, the suspension type high-frequency vibrating device is started to vibrate through the command issued by the vibration leveling intelligent control device, and the longitudinal walking device moves forward at the preset speed to realize high-frequency vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com