Feed liquid continuous separating, metering and disc distributing device

A technology of material liquid and plate separation, which is applied in the chemical industry, can solve problems such as threats to employees' lives and corporate property safety, material liquids that cannot meet design requirements, and product quality stability reduction, so as to reduce manual labor intensity and realize continuous automation. The effect of high efficiency in operation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

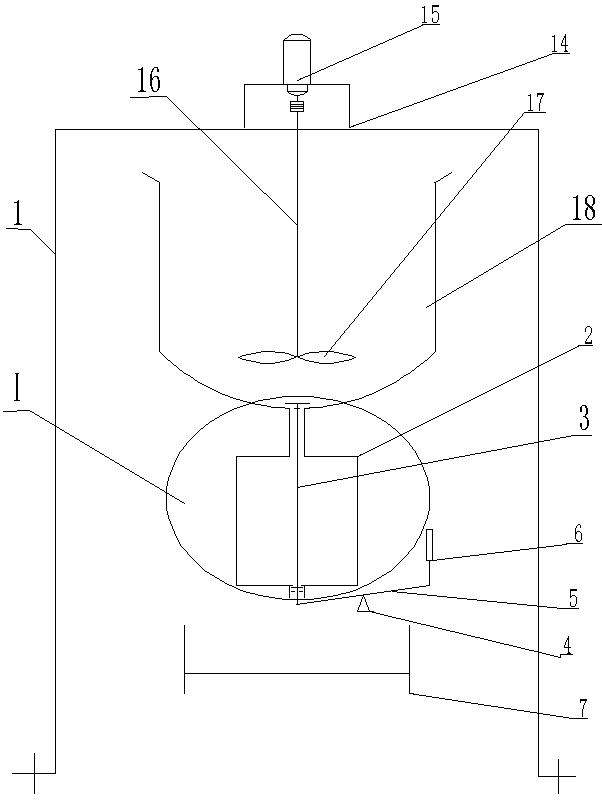

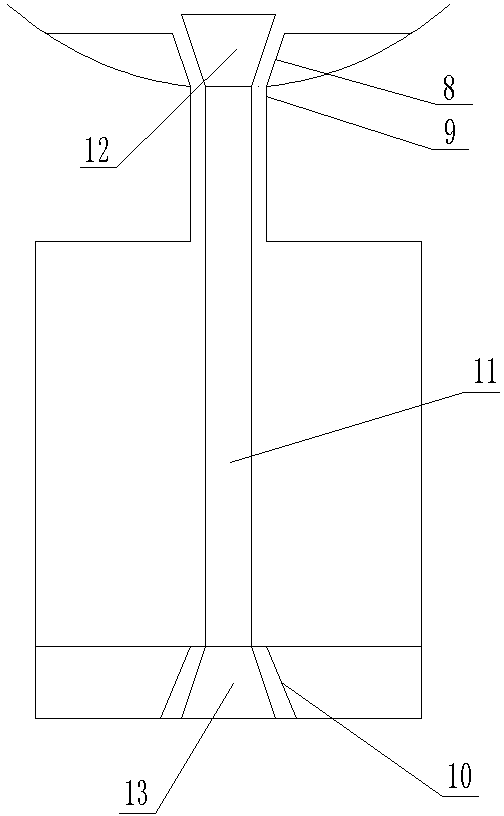

[0025] The invention includes a support 1, a material and liquid storage device, a metering tank 2, a one-piece switch 3, a support rod 4, a connecting rod 5 that can rotate around the support rod 4, a lifting cylinder 6, a medicine holding tray 7, a support 14, and a motor 15. Wherein, the material liquid storage device adopts a compound reaction kettle 18, and the compound reaction kettle 18 is arranged on the support 1. The bottom end of the feed liquid storage device is provided with a feed liquid outlet 8, and the top of the metering tank 2 is provided with a metering feed port 9, which is sealed and connected with the feed liquid outlet 8, and the bottom end of the metering tank 2 A metering outlet 10 is provided, the feed liquid outlet 8 is V-shaped, the metering outlet 10 is an inverted V shape, and a metal filter screen is arranged on the feed liquid outlet 8 . The connected switch 3 includes a rod body 11, a top seal 12, and a bottom seal 13. The length of the rod b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com