Water circulation method used in laboratory circulation-water-type water distiller

A technology for water distillers and laboratories, which is applied to laboratory containers, laboratory utensils, chemical instruments and methods, etc., and can solve the problem of fouling of spiral heating tubes, difficult removal of fouling, and reduced output efficiency, etc. problem, to achieve the effect of improving condensation efficiency, low maintenance cost and high output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

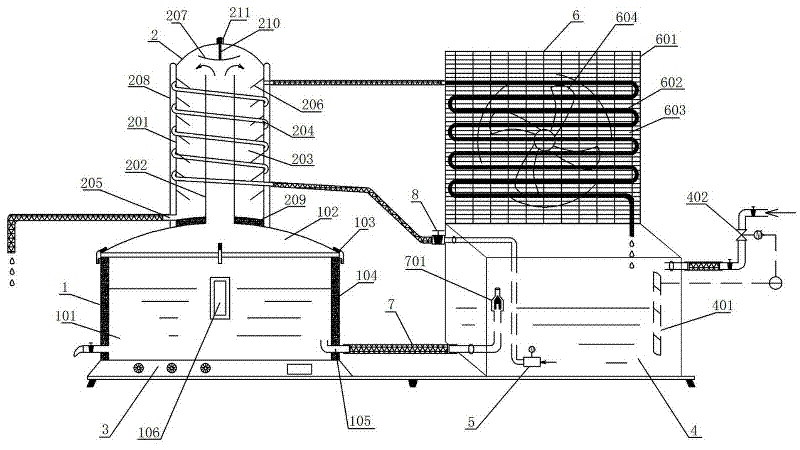

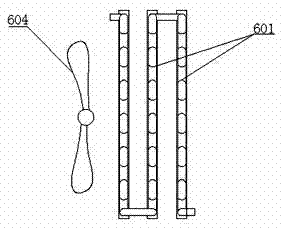

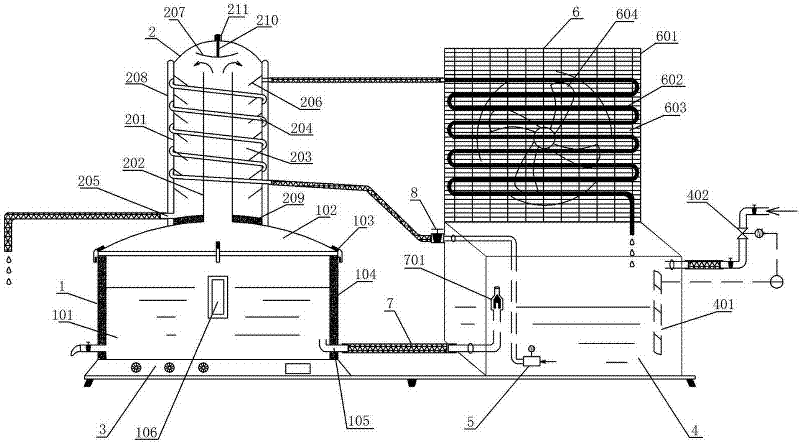

[0022] The water circulation method of the circulating water type distilled water device used in the laboratory is illustrated in conjunction with the accompanying drawings. The distilled water device used includes a steam generator and a water supply device. The water supply device includes a condensed water storage 4 and a radiator 6. The steam generator includes a distillation barrel 1 and a condenser. 2. The condenser 2 is arranged on the top cover 102 of the distillation barrel 1 , and the condenser 2 includes a condensation cover 201 and a steam guiding sleeve 202 vertically arranged in the condensation cover 201 . The water cycle method is:

[0023] The water in the condensed water storage 4 is delivered to the lower port of the spiral condensed water pipe 204 wound around the outside of the condensed water pipe 201 through the water supply pump 5, and the water passes through the condensed water pipe 204 to cool the condensed water pipe 201 and flows from the upper port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com