Process for electrolytic reduction preparation of metanilic acid

A technology of aminobenzenesulfonic acid and sodium nitrobenzenesulfonate, applied in the field of electrochemistry, can solve problems such as slow reaction speed, long production cycle, and environmental pollution, and achieve the effects of easy reaction, small scale effect, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

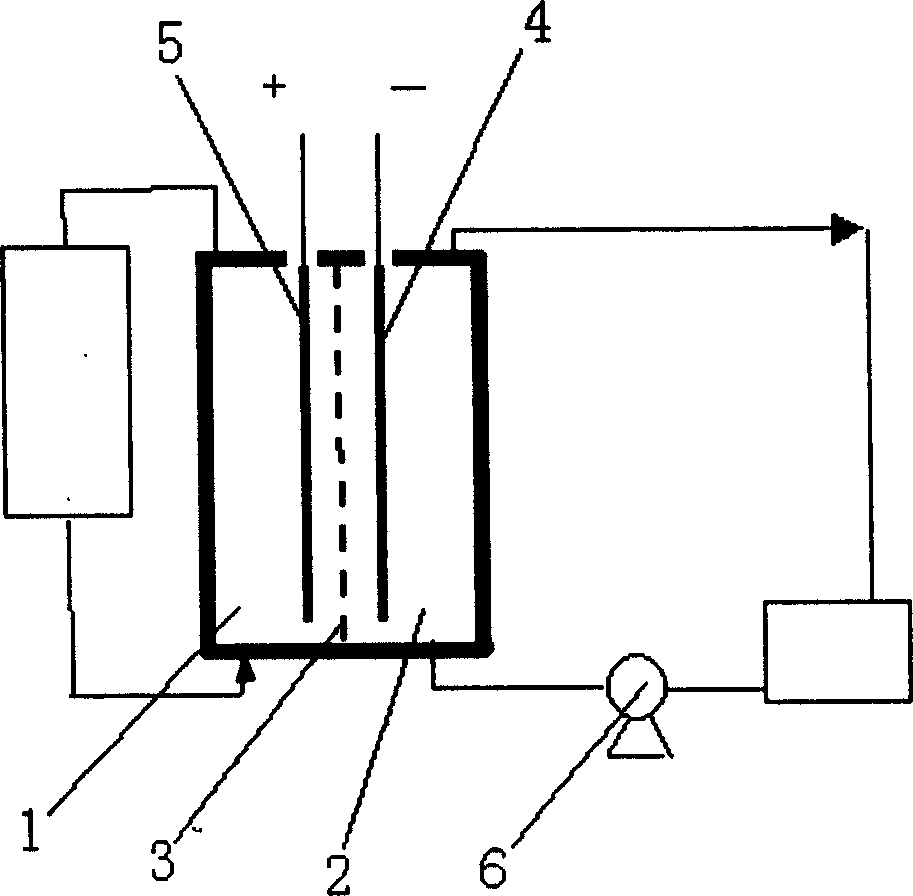

Method used

Image

Examples

Embodiment 1

[0030] A lead electrode is placed in the cathode chamber of the electrolytic cell as a working electrode, and a lead electrode is placed in the anode chamber as a counter electrode. Weigh 112.5 grams of sodium m-nitrobenzenesulfonate, dissolve in a small amount of water, add 5 ml of 5M sulfuric acid, add water to 250 ml, and make an electrolyte solution with a raw material concentration of 2.0 mol / L, add it to the cathode chamber of the electrolytic cell, and start the circulation pump. Heat to 40°C; add 5M sulfuric acid into the anode chamber as electrolyte. Electrolysis was carried out for 8 hours at a current intensity of 10A. After the electrolysis, the electrolytic solution was cooled to 4° C., crystallized, and filtered to obtain the m-aminobenzenesulfonic acid product. The yield of m-aminobenzenesulfonic acid was 96.49%.

Embodiment 2

[0032] A copper electrode is placed in the cathode chamber of the electrolytic cell as a working electrode, and a lead electrode is placed in the anode chamber as a counter electrode. Weigh 5.6 grams of sodium m-nitrobenzene sulfonate, dissolve in a small amount of water, add 40 ml of 5M sulfuric acid, add water to 250 ml, make an electrolyte solution with a raw material concentration of 0.1 mol / L, and add it to the cathode chamber of the electrolytic cell. Turn on the circulating pump and heat to 40°C; add 0.1M sulfuric acid to the anode chamber, and conduct electrolysis at a current intensity of 2A for 2 hours. The yield of aminobenzenesulfonic acid was 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com