Thin-layer reactive powder concrete vibrating and levelling method and system

A kind of active powder and concrete technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of low efficiency, inability to realize automatic continuous operation, low flatness, etc., and achieve efficiency improvement, flatness improvement, leveling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

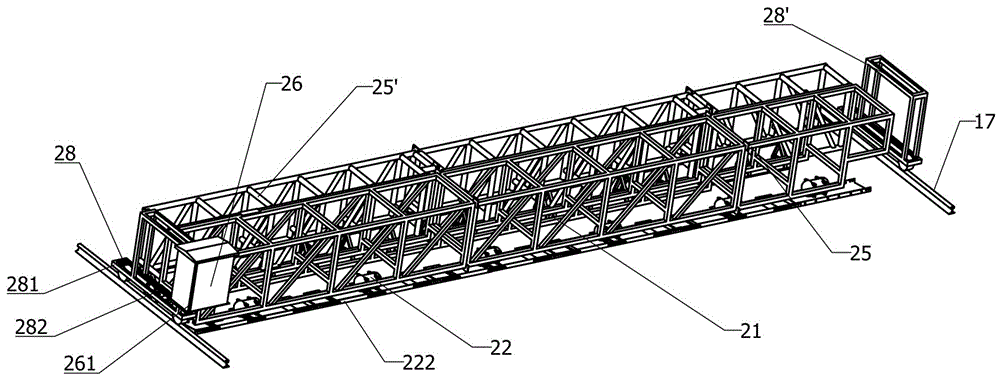

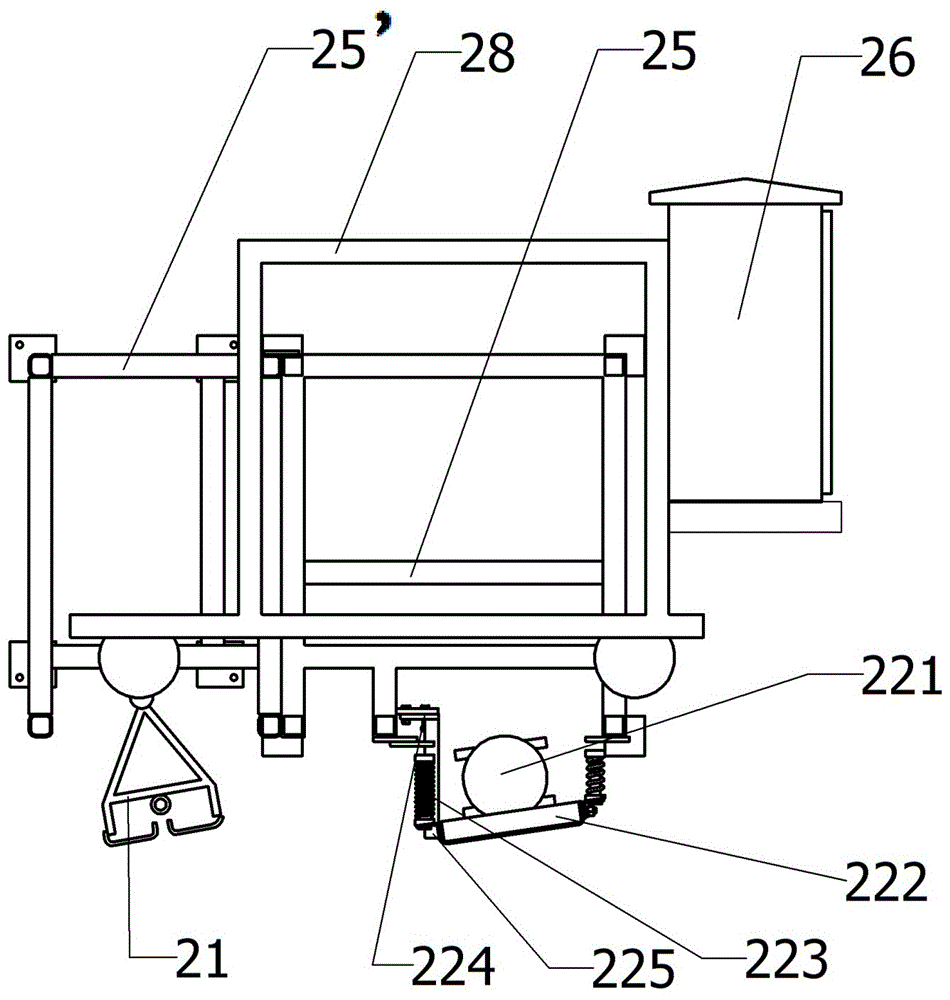

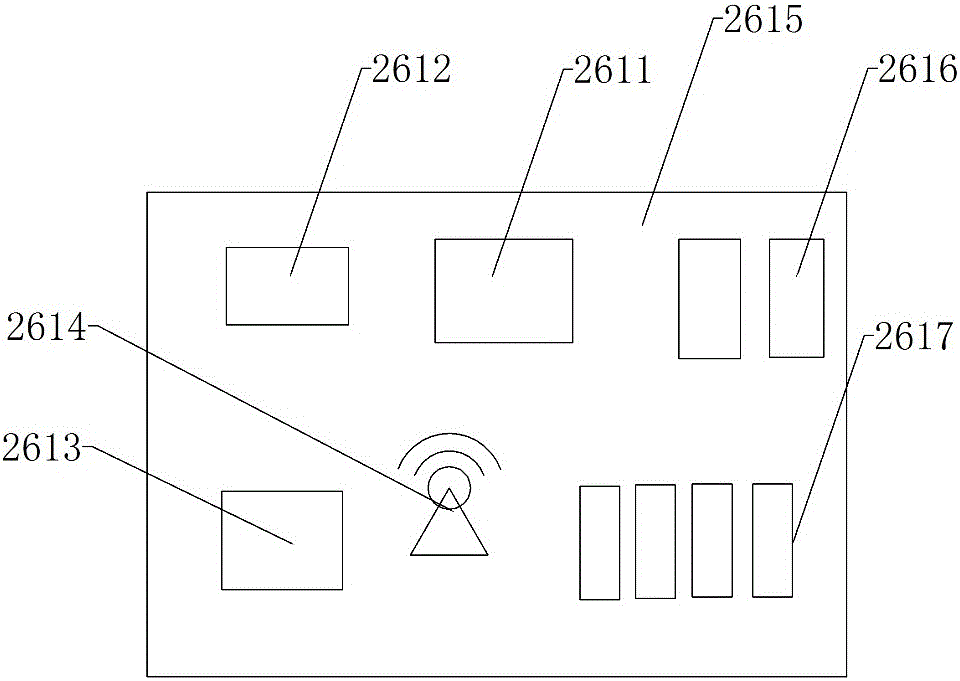

[0035] Embodiment 1, the present invention includes a vibrating truss 25, a suspended high-frequency vibrating device 22, a suspended leveling device 21, a vibrating and leveling parallel walking device 28, and a vibrating and leveling intelligent control device 26, wherein the suspended high-frequency vibrating device 22 Suspended below the advancing direction of the vibrating truss 25, the suspended leveling device 21 is suspended below the advancing direction of the vibrating truss 25; The leveling intelligent control device 26 is installed on the sides of the two ends of the vibrating truss 25, and the entire vibrating and leveling system is installed on the longitudinal rail 17. When the system is working, the vibrating and leveling parallel traveling device 28 is first started to move forward. The suspended high-frequency vibrating device When the vibrating plate 222 of 22 touches the active powder concrete, the high-frequency vibration motor 221 is turned on, and the lev...

Embodiment 2

[0036] Embodiment 2, the suspended high-frequency vibrating device 22 of the present invention includes a vibrating truss 25, a high-frequency vibrating motor 221, a vibrating plate 222, an elastic suspension device 223, and a vibrating plate bevel adjustment device 224, wherein each vibrating plate 222 is Install a high-frequency vibration motor 221, the vibrating plate 222 is at an angle of 1°~70° to the horizontal, the elastic suspension device 223 is installed under the vibrating truss 25, and a vibration damping device 225 is arranged between the elastic suspension device 223 and the vibrating plate 222 . The angle between the vibrating plate 222 and the horizontal direction is adjusted by the vibrating plate oblique angle adjustment device 224 . The vibrating truss 25 drives the vibrating plate 222 to realize the function of moving up and down. refer to Figure 1 to Figure 7 , and the rest are the same as the combination of any of the above embodiments or two or more e...

Embodiment 3

[0037] Embodiment 3, the vibrating plate 222 of the suspended high-frequency vibrating device 22 of the present invention can be formed by connecting more than one plate, and a group of plate chains with a length of 0.3 to 50 m can complete the vibrating operation once in this wide section range; the vibrating plate Set 20~100mm high coaming panels around 222, set one hanging hook on the front coaming panel, set two hanging hooks on the rear coaming panel, and connect the hooks and the coaming panel with hinged hole bolts. refer to Figure 1 to Figure 7 , and the rest are the same as the combination of any of the above embodiments or two or more embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com