Sorting and separation process for comprehensive utilization of slag

A sorting and process technology, applied in solid separation, wet separation, grain processing, etc., can solve the problems of high carbon content and mud content in slag, unenvironmental production process, large dust, etc., and achieve high resource utilization rate. , Solve the problem of secondary pollution, the effect of small mud content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

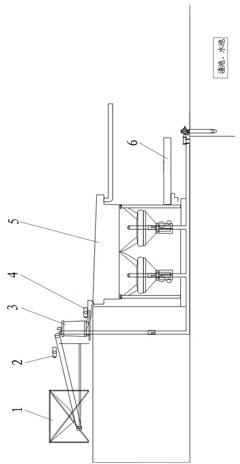

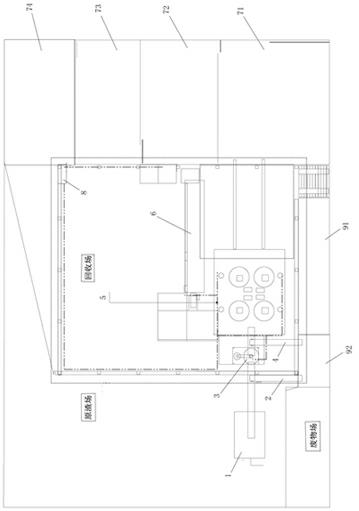

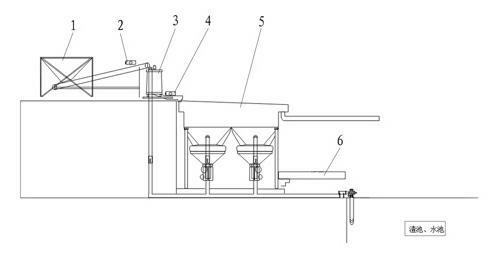

[0024] Example: see figure 1 and figure 2 , a sorting and separation process for comprehensive utilization of slag, comprising the following steps:

[0025] (1) The pretreated raw slag is subjected to wet crushing, and then magnetic separation is carried out to select the crushed iron particles. The slag material enters gravity separation and uses water as the separation medium to separate light products, heavy products and intermediate products. fine material;

[0026] (2) The light products of gravity separation are slag ash and sundries with light density and enter into the sediment pool; the heavy products of gravity separation are metals, and the intermediate fine materials are sand and enter the sand bin;

[0027] (3) The gravity-separated metals are purified and classified by the beneficiation shaker.

[0028] The technical process of the invention is mainly applied to domestic garbage incineration slag (including solid residues of other recyclable metal impurities)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com