Hydroxypropyl chitosan microspheres as well as preparation method thereof and application thereof in reduction of dielectric loss of vegetable oil

A technology of hydroxypropyl chitosan and chitosan, which is applied in its preparation, hydroxypropyl chitosan microspheres, and the application field of reducing the dielectric loss of vegetable oil, can solve the problem of agglomerating molecular chains and reduce the contact of oil products. area, reducing chelation, electrical neutralization and adsorption bridging, etc., to achieve the effects of stable and reliable structure, large specific surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

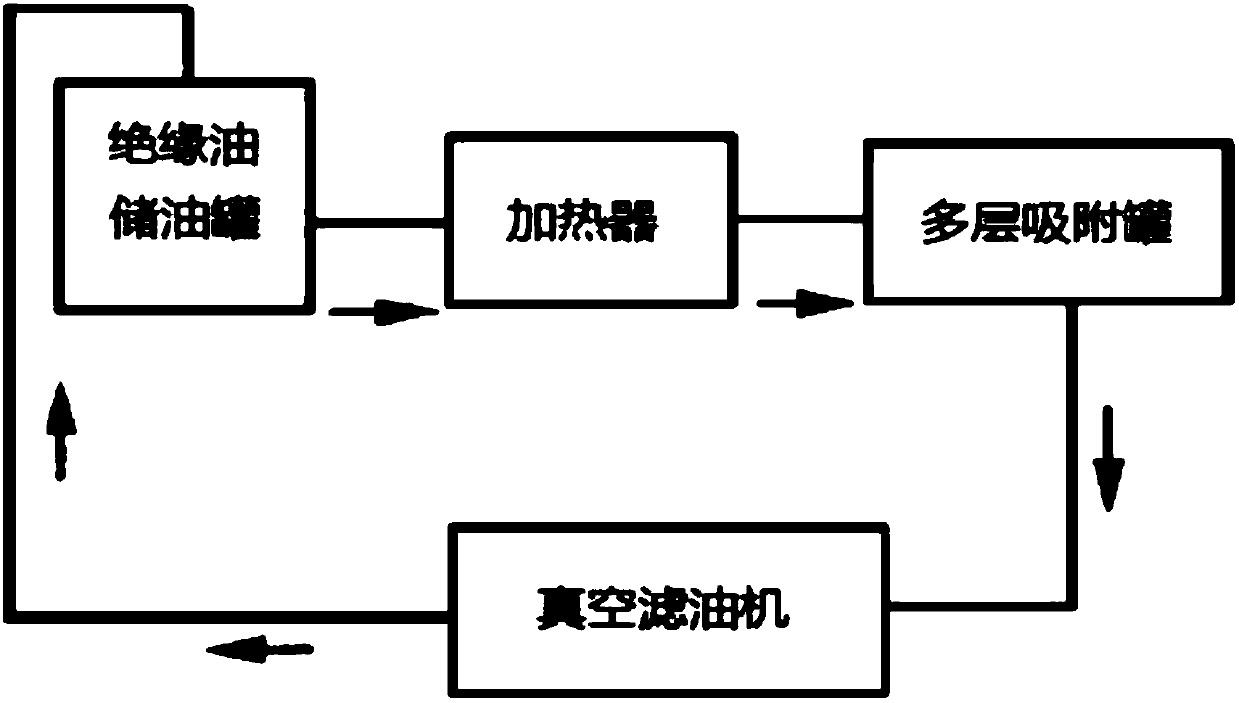

Method used

Image

Examples

preparation example Construction

[0034] The present embodiment provides a kind of preparation method of hydroxypropyl chitosan microsphere, comprises the following steps:

[0035] S1. Put chitosan and isopropanol with a viscosity of 0.25 to 0.65 Pa·s into the first sodium hydroxide solution, mix and stir evenly to obtain a solution, add tetramethylammonium hydroxide to the solution, and then drop propylene oxide Reaction to obtain a reaction solution, after cooling the reaction solution, use hydrochloric acid to adjust the pH to 7, then disperse in acetone or water, stir and filter with suction, then wash with absolute ethanol, and vacuum dry to obtain hydroxypropyl chitosan; preferably, the first hydrogen The mass concentration of sodium oxide solution is 10-20%, the mass ratio of chitosan, isopropanol and propylene oxide is 1-2:10-25:10-20, chitosan and isopropanol are put into the first hydrogen The sodium oxide solution is mixed and stirred at 25-35° C. for 0.5-1.5 hours; preferably, propylene oxide is dr...

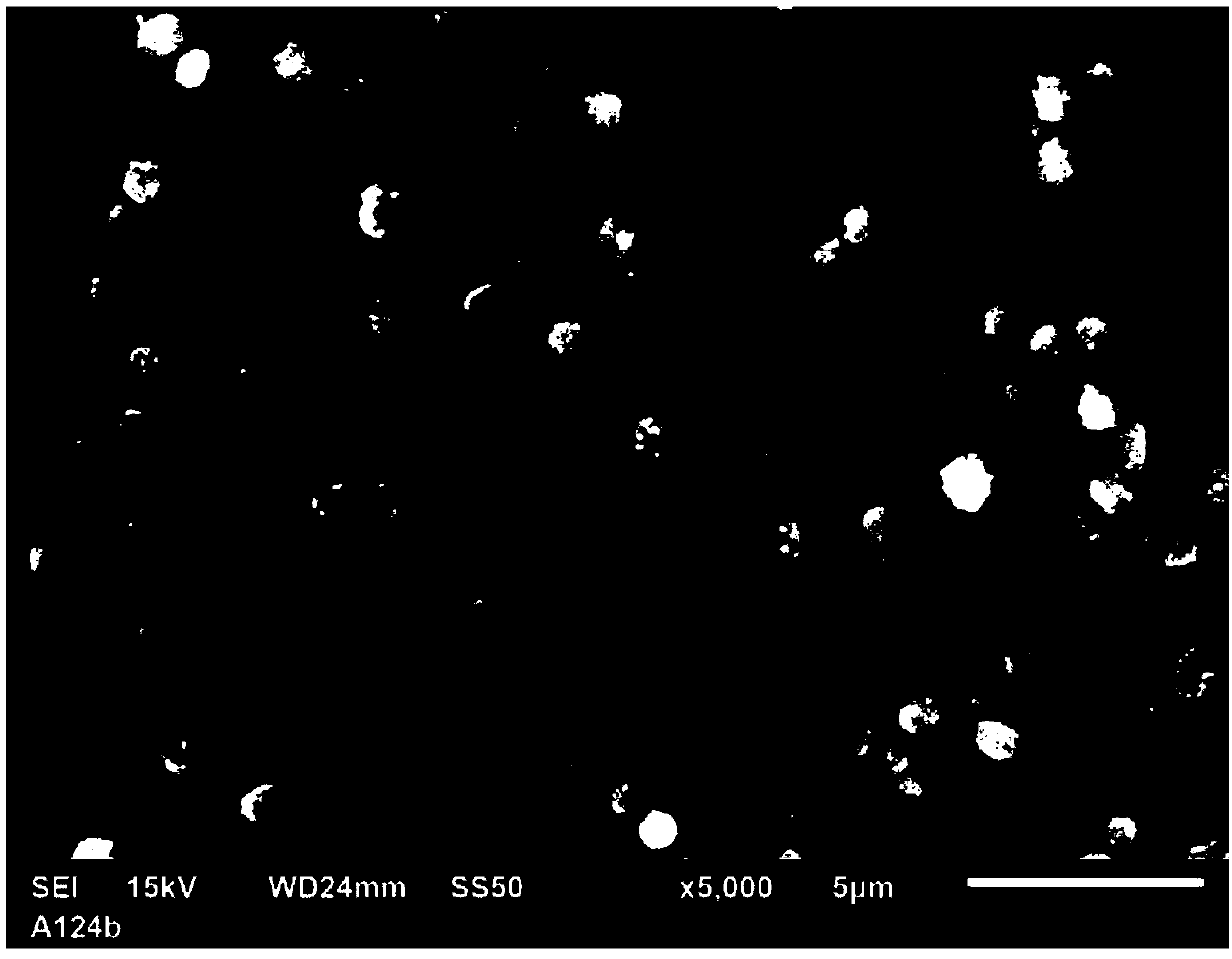

Embodiment 1

[0045] The present embodiment provides a kind of hydroxypropyl chitosan microsphere, and its specific preparation method is as follows:

[0046] S101, preparing a hydroxypropyl chitosan solution with a mass fraction of 0.5%; putting chitosan and isopropanol in a mass ratio of 1:15 into the first sodium hydroxide solution with a mass concentration of 10% at 30°C Mix and stir for 1 hour to obtain a solution, add tetramethylammonium hydroxide to the solution, drop propylene oxide and stir at 60°C for 5 hours to obtain a reaction solution. The mass ratio of chitosan and propylene oxide is 1:10. After the reaction solution is cooled, use hydrochloric acid to adjust the pH to 7, then disperse in acetone or water, stir and filter, then wash with absolute ethanol, and vacuum dry to obtain hydroxypropyl chitosan; dissolve hydroxypropyl chitosan in water to prepare The mass fraction is 0.5% hydroxypropyl chitosan solution; wherein the viscosity of chitosan is 0.48Pa·s;

[0047] S102, t...

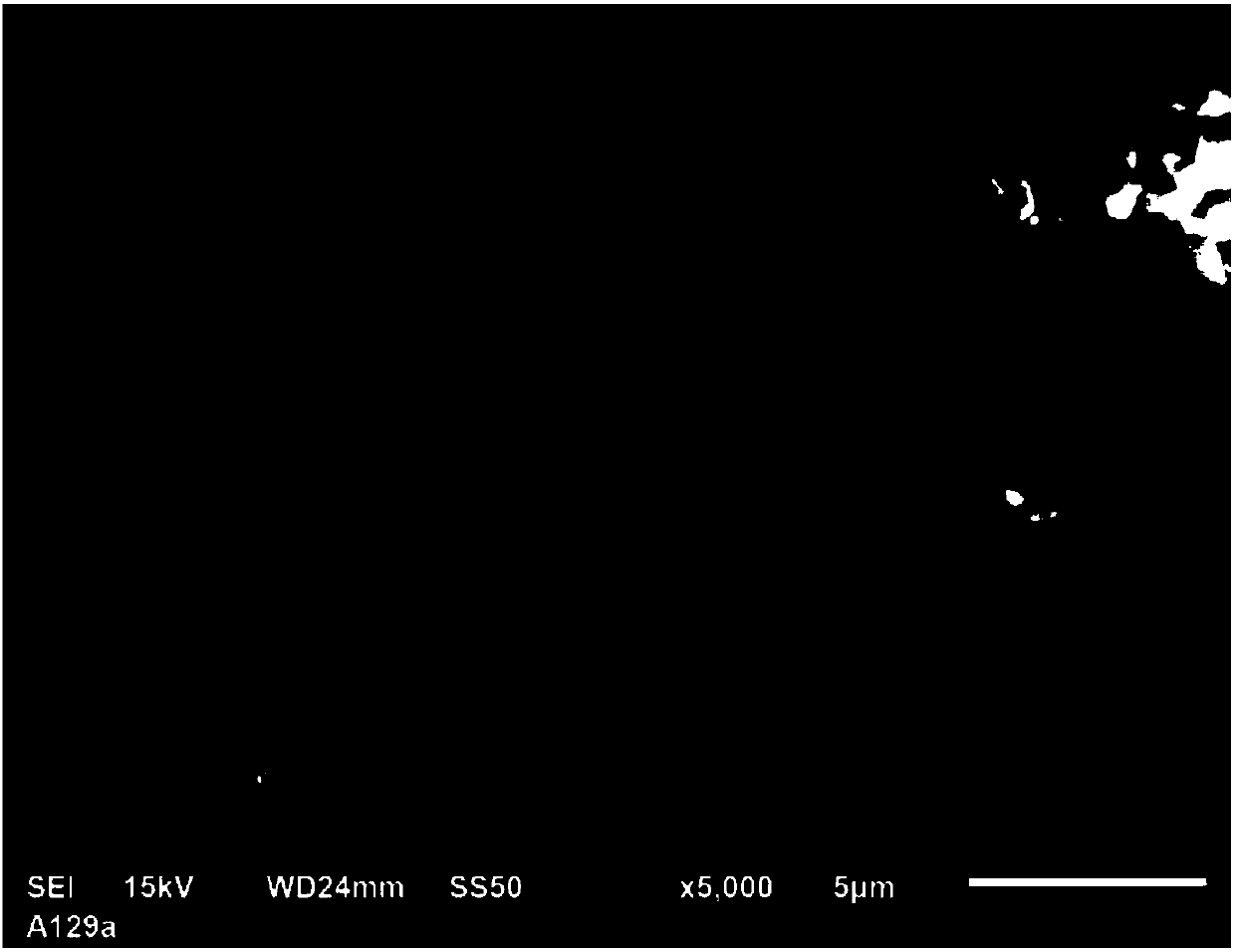

Embodiment 2

[0051] The present embodiment provides a kind of hydroxypropyl chitosan microsphere, and its specific preparation method is as follows:

[0052] S201, preparing a hydroxypropyl chitosan solution with a mass fraction of 2%; putting chitosan and isopropanol in a mass ratio of 1:20 into the first sodium hydroxide solution with a mass concentration of 15% at 25°C Mix and stir for 1 hour to obtain a solution, add tetramethylammonium hydroxide to the solution, drop propylene oxide, stir and react at 55°C for 5 hours to obtain a reaction solution, the mass ratio of chitosan and propylene oxide is 1:15, and After the reaction solution is cooled, use hydrochloric acid to adjust the pH to 7, then disperse in acetone or water, stir and filter, then wash with absolute ethanol, and vacuum dry to obtain hydroxypropyl chitosan; dissolve hydroxypropyl chitosan in water to prepare The mass fraction is 2% hydroxypropyl chitosan solution; wherein the viscosity of chitosan is 0.54Pa·s;

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com