Machine for automatically mounting battery cell of square power battery into shell

A technology of power battery and casing machine, which is applied in the direction of battery assembly machine, secondary battery manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of improving production efficiency, improving production quality, and ensuring efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

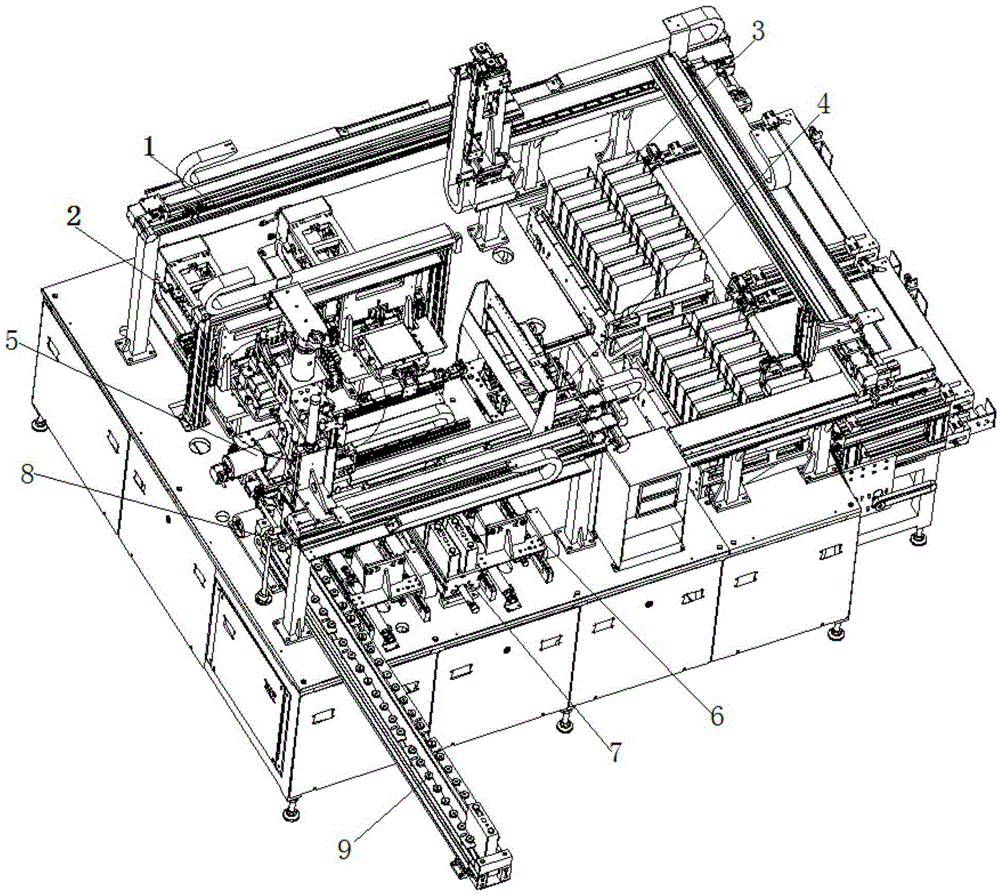

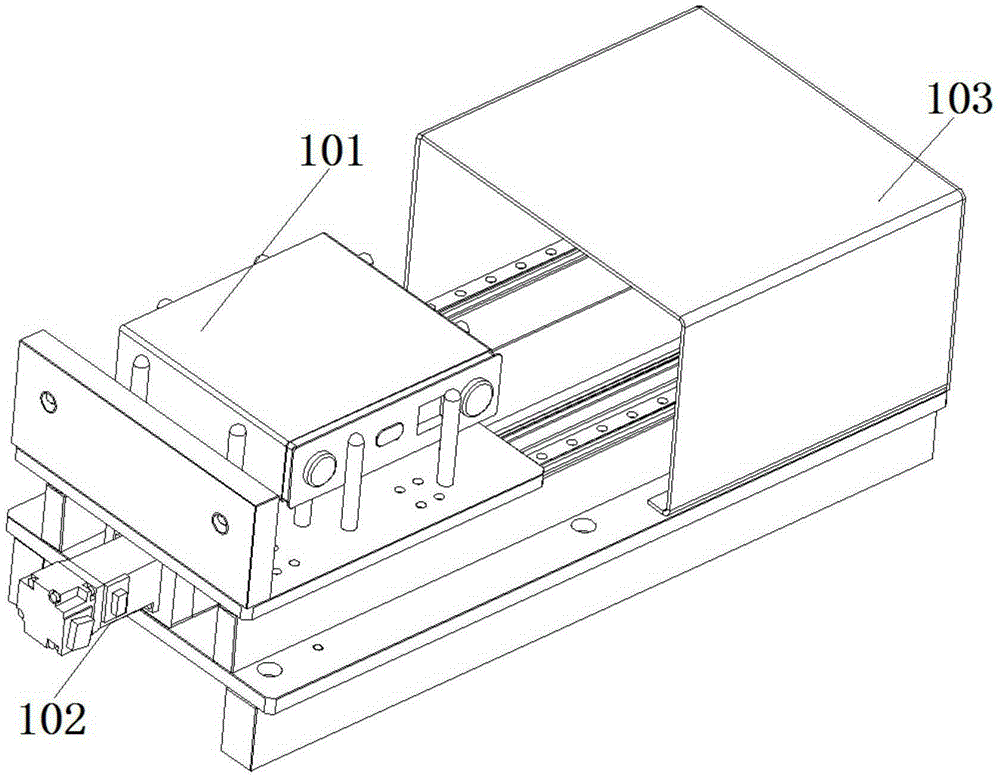

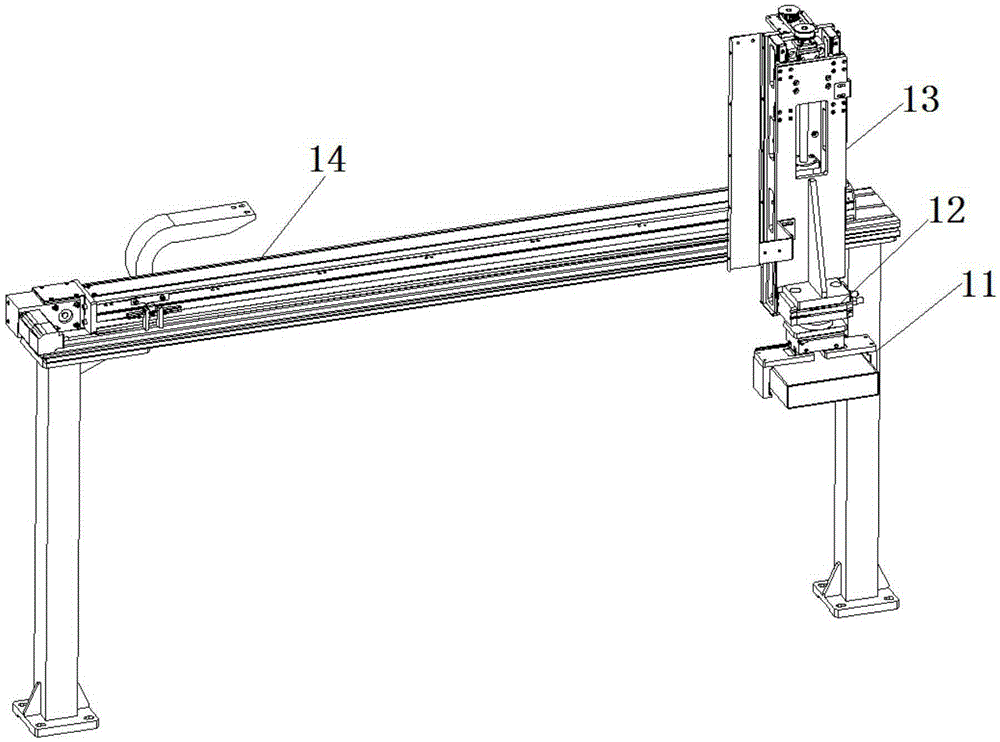

[0048] Such as Figure 1-12 As shown, it shows the specific implementation of the present invention; as shown in the figure, the square power battery automatic shelling machine disclosed by the present invention is used to pack the bare cells packed with Mylar into the aluminum shell; it includes a frame ; The frame is provided with a bare cell dust removal assembly for dedusting the bare cell; the frame is also provided with an aluminum shell feeding assembly for conveying the aluminum shell; the frame is also provided with a The aluminum shell dust removal component that removes dust from the aluminum shell on the aluminum shell feeding assembly; the dust removal structure is set to ensure the battery quality, and the mechanized dust removal also ensures the efficiency and quality;

[0049] The frame is also provided with a shell-in tooling assembly for loading the bare cell into the aluminum shell; the shell-in tooling assembly includes a bare cell discharge position and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com