Automatic gluing, edge turning and laminating system for packaging carton

A gluing and automatic technology is applied in the fields of flanging, automatic gluing of packaging cartons, pressing system, and carton processing equipment. and other problems, to achieve the effect of saving manpower, improving molding quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

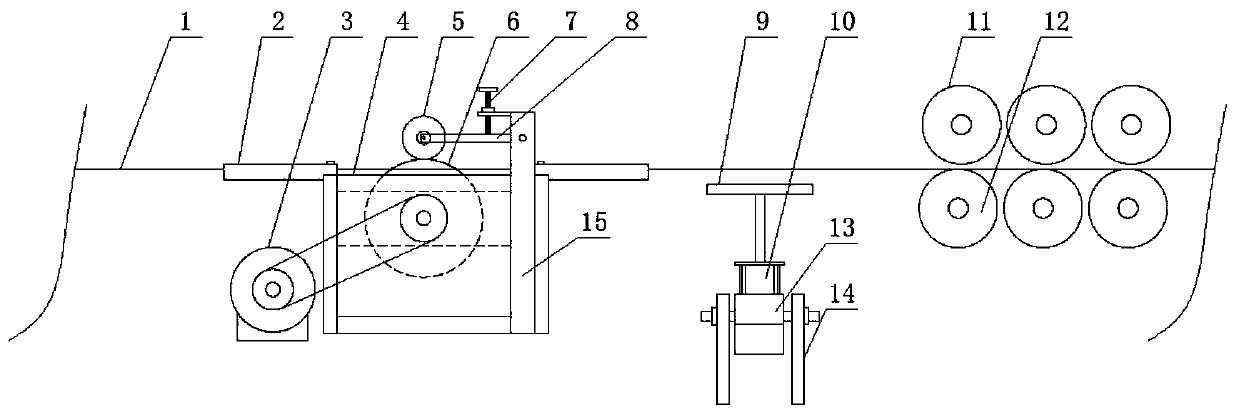

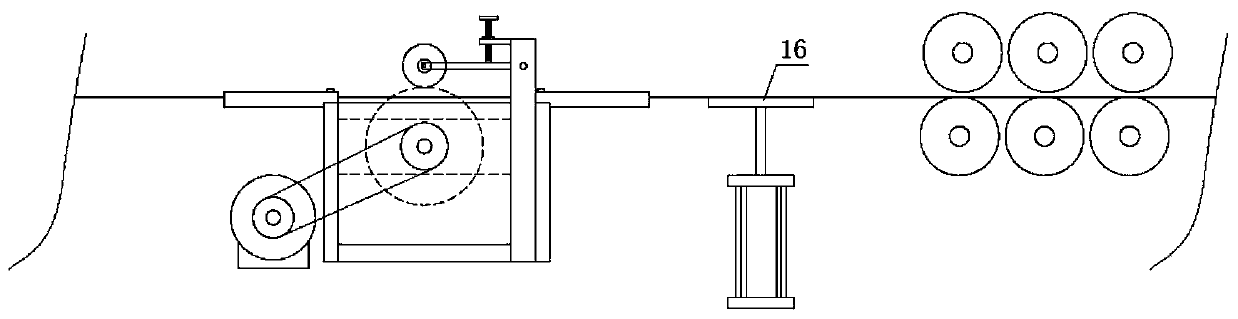

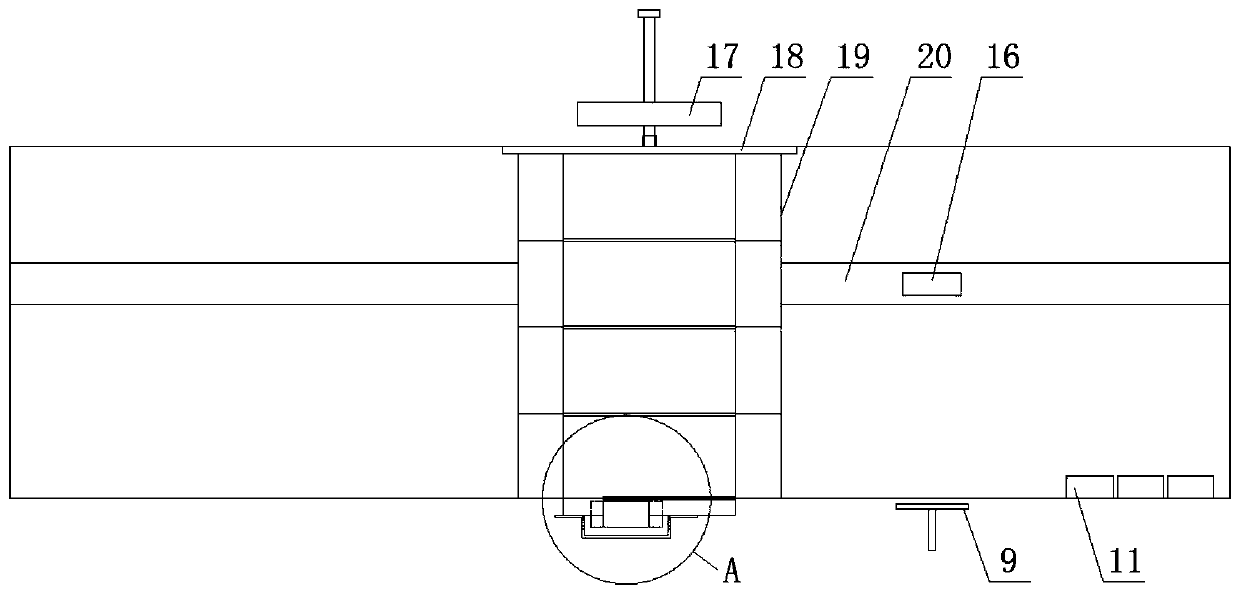

[0027] An automatic gluing, flanging, and pressing system for packaging cartons. The frame is provided with two parallel conveyor belts synchronously driven by the motor, and there is a flap gap 20 between the two conveyor belts. In the conveying direction of the conveyor belt, there are glue-applied indentation mechanisms and pressing structures in sequence from front to back. A flanging mechanism located on the outside of the conveyor belt and a turnover mechanism located inside the frame are arranged between the gluing indentation mechanism and the pressing mechanism, and the turnover head 16 of the turnover mechanism expands and contracts at the gap between the turnover panels.

[0028] The gluing and creasing mechanism is composed of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com