Thick-type paperback perfect binding method

A technology for paperback books and signatures, which is used in book binding, binders for binding, and printing. It can solve the problems of poor after-sales service, long supply cycle, low efficiency, etc. The effect of easy adjustment, improved production efficiency, and reduced distribution costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

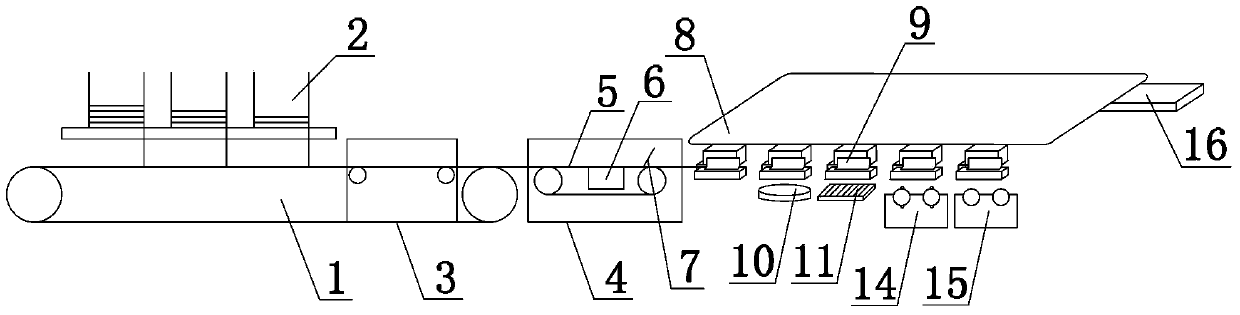

[0020] A method for perfect binding of a thick paperback book, when printing with a folio offset printing machine to prepare a thick paperback book with 1344 pages of 16K, the specific steps of the method are:

[0021] Step (1), place the folded signatures in the order of page numbers in the 1st to n collation stations 2 of the collating machine 1, the collating machine 1 is a swing-arm type collating machine, and the collating machine 1 Paging machine 1 is a 7-tower collating machine, each tower is three, that is, the collating machine 1 has 21 collating stations, and n is 1, 2, 3...21; after the first posting, Align pages 1-336; collide the entire stack of signatures through the paper breaker 4, convey the entire stack of signatures through the conveyor belt 5, bump the bottom of the entire stack of signatures through the vibrating motor 6, and align the entire stack of signatures through the stop gauge 7 The front part of the stack of signatures is aligned; the entire stack...

Embodiment 2

[0025] A method for perfect binding of thick paperback books. When printing with a full-format offset printing machine to prepare 1680 pages of 16K thick paperback books, the specific steps of the method are:

[0026] Step (1), the folded signatures are placed in the 1-nth collating station 2 of the collating machine 1 in the order of page numbers, the collating machine 1 is a swing-arm collating machine, and the collation Paging machine 1 is a 7-tower collating machine, each tower is three, that is, the collating machine 1 has 21 collating stations, and n is 1, 2, 3...21; after the first posting, Align pages 1-672; collide the entire stack of signatures through the paper breaker 4, transmit the entire stack of signatures through the conveyor belt 5, bump the bottom of the entire stack of signatures through the vibration motor 6, and align the entire stack of signatures through the stop gauge 7 The front part of the stack of signatures is aligned; the entire stack of signature...

Embodiment 3

[0030] A method for perfect binding of thick paperback books. When printing with a quarto format offset printing machine to prepare 880 pages of 16K thick paperback books, the specific steps of the method are:

[0031]Step (1), the folded signatures are placed in the 1-nth collating station 2 of the collating machine 1 in the order of page numbers, the collating machine 1 is a swing-arm collating machine, and the collation Paging machine 1 is a 7-tower collating machine, each tower is three, that is, the collating machine 1 has 21 collating stations, and n is 1, 2, 3...21; after the first posting, Align pages 1-168; collide the entire stack of signatures through the paper feeder 4, convey the entire stack of signatures through the conveyor belt 5, bump the bottom of the entire stack of signatures through the vibrating motor 6, and align the entire stack of signatures through the stop gauge 7. The front part of the stack of signatures is aligned; the entire stack of signatures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com