Device and method for measuring relationship between lateral vibration displacement and strain of flexible beam

A technology of lateral vibration and displacement, applied in the direction of measuring devices, electromagnetic measuring devices, electrical devices, etc., to achieve the effect of less glue, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

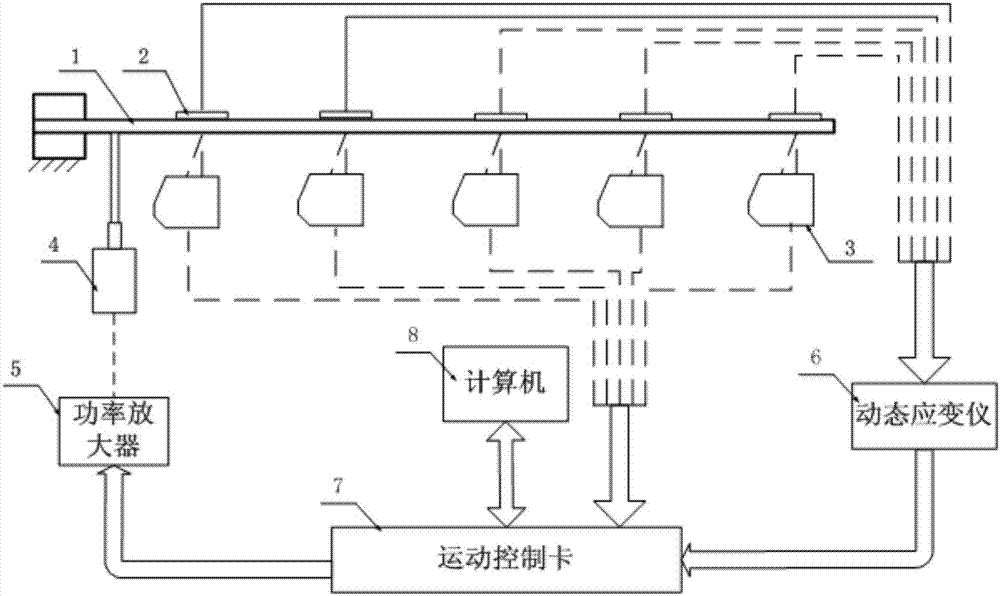

[0022] Such as figure 1 As shown, a device for measuring the relationship between lateral vibration displacement and strain of a flexible beam includes a flexible cantilever beam 1. One end of the flexible cantilever beam is fixed to a base, and the other end is free to vibrate as a free end. Install multiple resistance strain gauges 2 on the front or back, and install multiple laser displacement sensors 3 for measuring the vibration lateral displacement at the geometric center point of the resistance strain gauge on the other side of the resistance strain gauge, according to the measured strain signal and lateral displacement signal , It is used to analyze the relationship between lateral vibration displacement and strain distribution of flexible beams.

[0023] In this embodiment, five laser displacement sensors 3 are installed in front of the other side of the flexible cantilever beam, with equal intervals in a line arrangement. One side of the flexible cantilever beam 1 is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com