Miniature type surface mounting single-phase full-wave bridge rectifier and manufacturing method of rectifier

A full-wave bridge rectification, surface mount technology, applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem of affecting the final performance of the product, increasing the chip damage rate, and increasing the lateral shear force and other problems, to achieve the effects of less deformation, less total thickness and easier positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

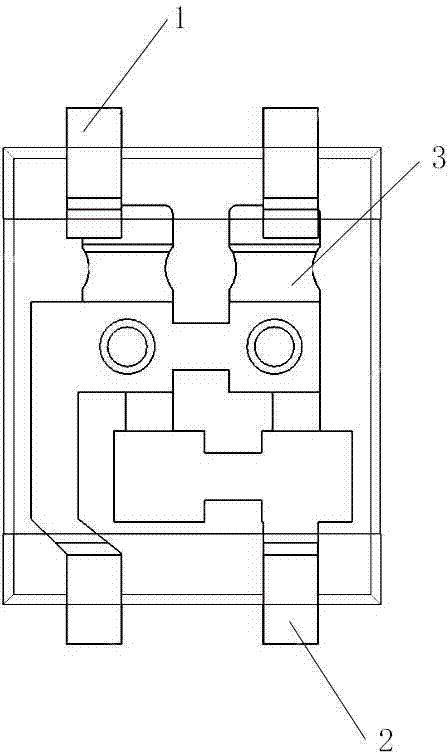

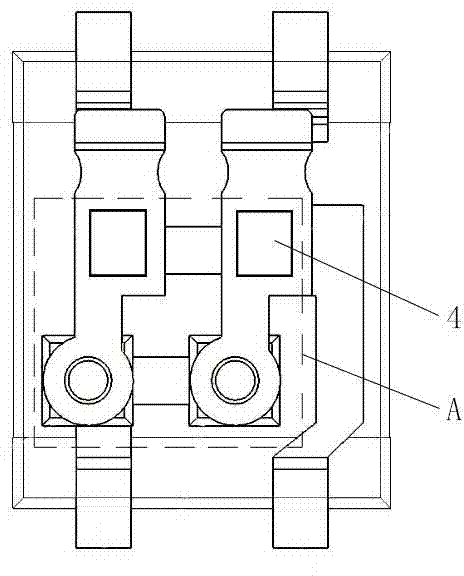

[0023] Such as Figure 1-4 As shown, the miniature surface mount single-phase full-wave rectifier is composed of a monolithic frame unit 6 and a lower pin unit 7; the monolithic frame unit 6 and the lower pin unit 7 include 5 rectifiers forming a bridge rectifier circuit Parts of the chip: a group of two input terminals 1 , a group of two output terminals 2 , a group of two connecting jumpers 3 , a group of four chips 4 , and a plastic package 5 .

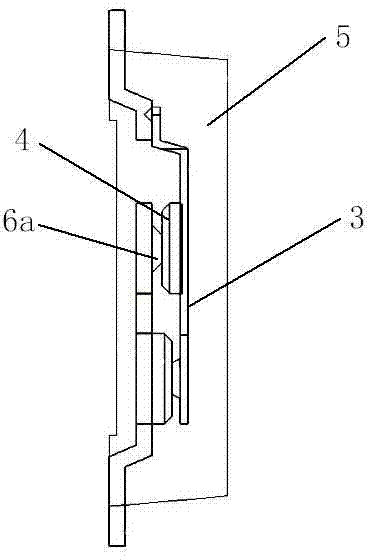

[0024] Such as Figure 5 As shown, the monolithic frame unit 6 includes two flat pads 6a, two bump pads 6b, a large frame 6c, a small frame 6d, an output terminal 2 and a connecting jumper 3. The large frame 6c has a gradient for the part where the end part is combined with the output terminal, and the whole is an inverted L shape. There are two flat pads 6a on the horizontal horizontal surface, and the small frame 6d is a belt for the part where the end part is combined with the output terminal. There are gradients, the overall ...

Embodiment 2

[0037] The four rectifier chips A forming the bridge rectifier circuit are glass-passivated fast-recovery rectifier chips or Schottky rectifier chips, and the shape of the flat pad 6a is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com