Integral covered bagged spring cushion

A pocket spring and cover-type technology, which is applied in the field of spring pads, can solve problems such as health and environmental impacts, affect people's health, increase production costs, etc., and achieve increased conformity and comfort, good repeatability, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

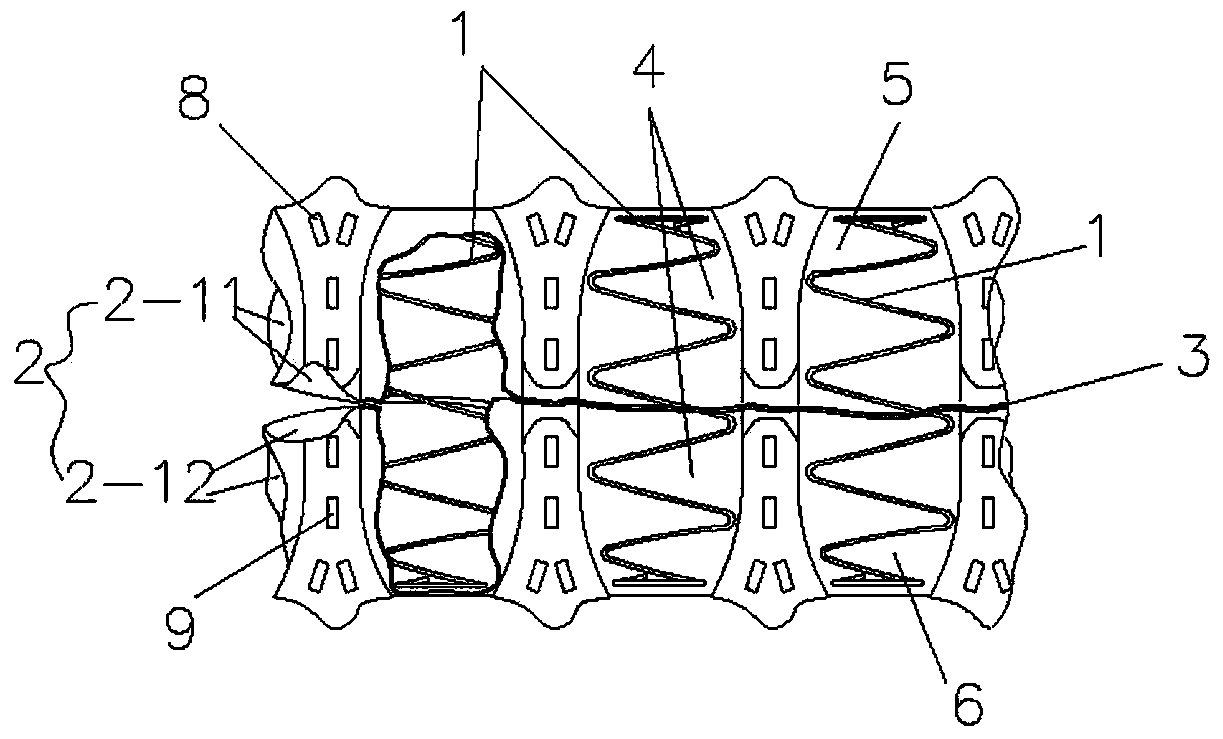

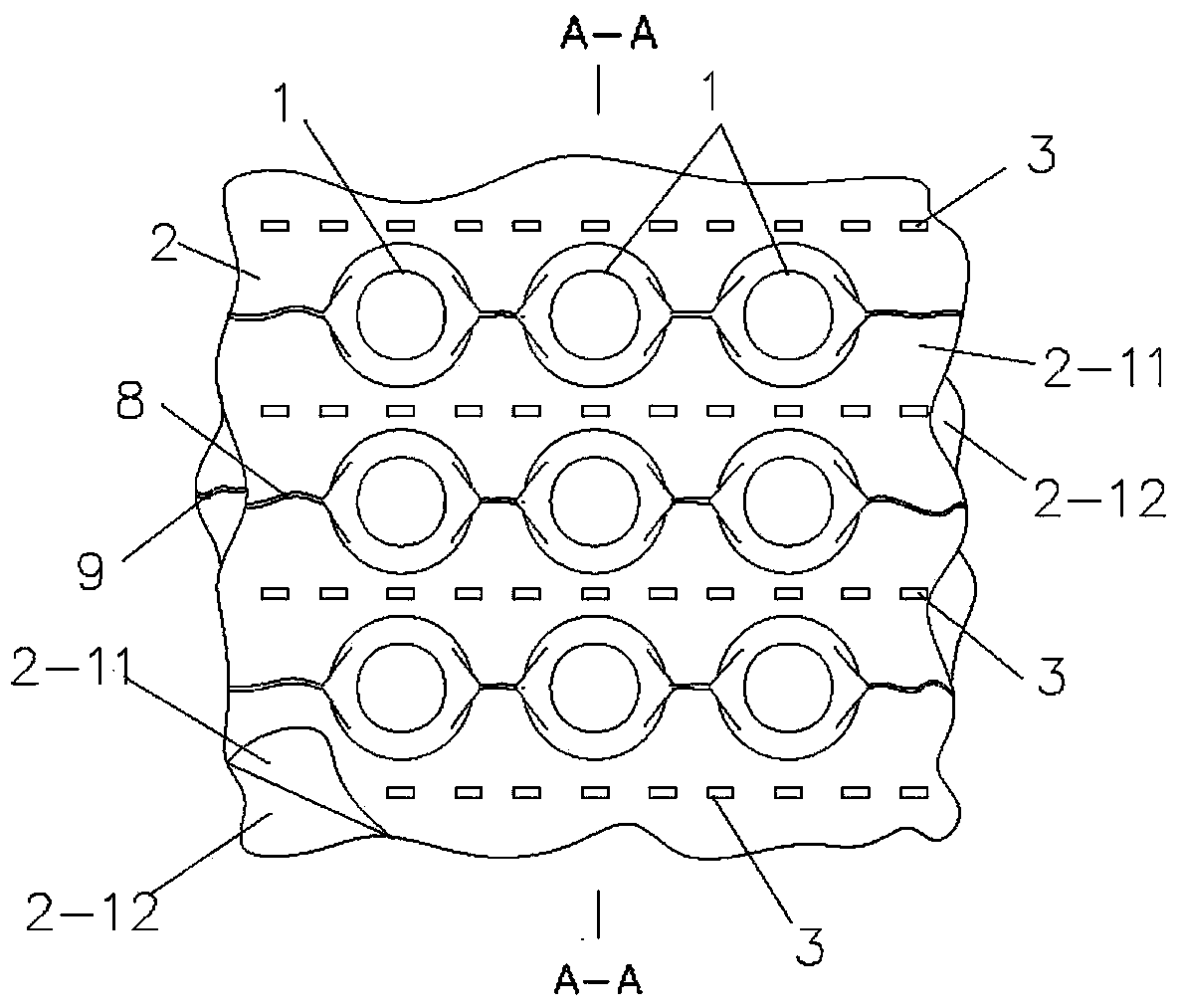

[0032] Combine the following Figure 2 to Figure 10 The present invention is further described in detail.

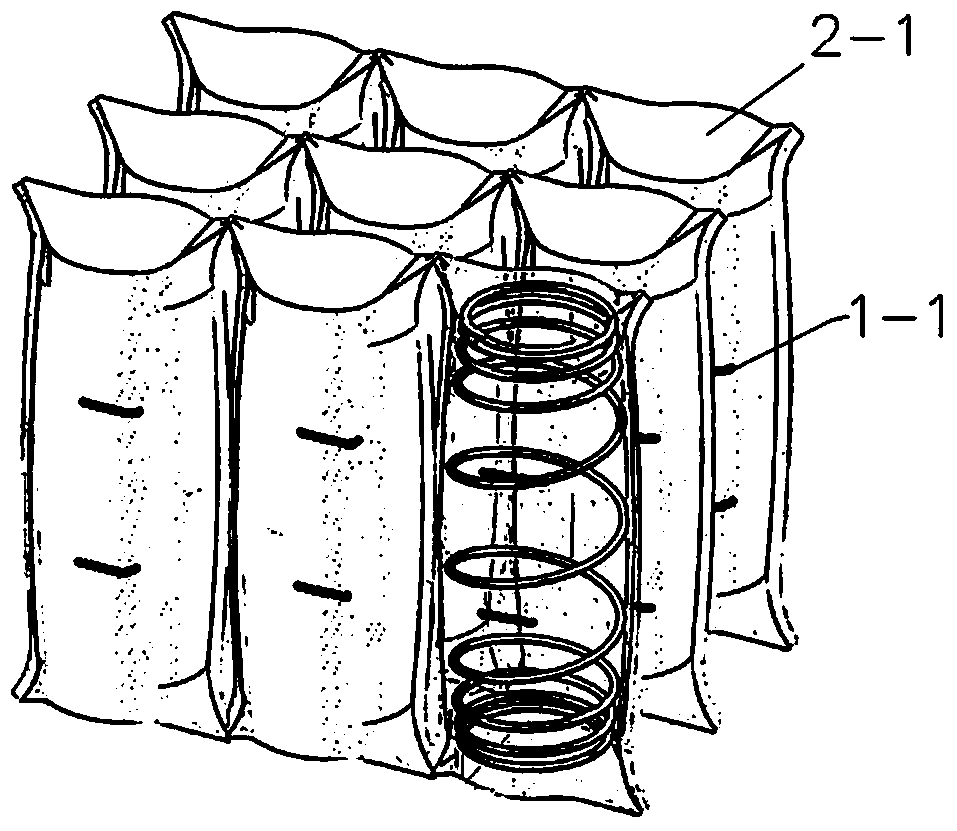

[0033] The overall cover type pocket spring pad includes several rows of helical spring rows 1 and two layers of joint cloth 2, and the individual springs of the several rows of helical spring rows 1 are arranged vertically and horizontally. The seams 3 of the two-layer fabrics are distributed between the adjacent coil spring rows 1, and the seams 3 of the two-layer fabrics can be joined in single-row joints, double-row joints, multi-row joints, arc joints or special-shaped joints. , the joint seam 3 of the two layers of cloth is perpendicular to the individual axis of the spring. The upper partition 8 of the upper cover body 5 formed by the upper layer of cloth is distributed between the spring individuals of the coil spring row 1; the lower partition 9 of the lower cover body 6 formed by the lower layer of cloth is distributed between the spring individuals of the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com