Information driven leather shoe preparation method

A manufacturing method, information-driven technology, applied in the direction of footwear, shoe-making machinery, comprehensive factory control, etc., can solve the problems of inability to meet individual needs, slow product update speed, unstable manufacturing quality, etc., to ensure workers The effect of health, reducing manual participation, and improving the level of intelligence

Inactive Publication Date: 2008-10-15

ZHEJIANG SCI-TECH UNIV

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This typical shoe-making method is mainly based on labor and supplemented by machinery and equipment, which exposes workers to harsh production environments, resulting in unstable manufacturing quality, relatively large consumption of materials, poor flexibility in leather shoe manufacturing, and product renewal. The replacement speed is slow and cannot meet the individual needs of each customer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

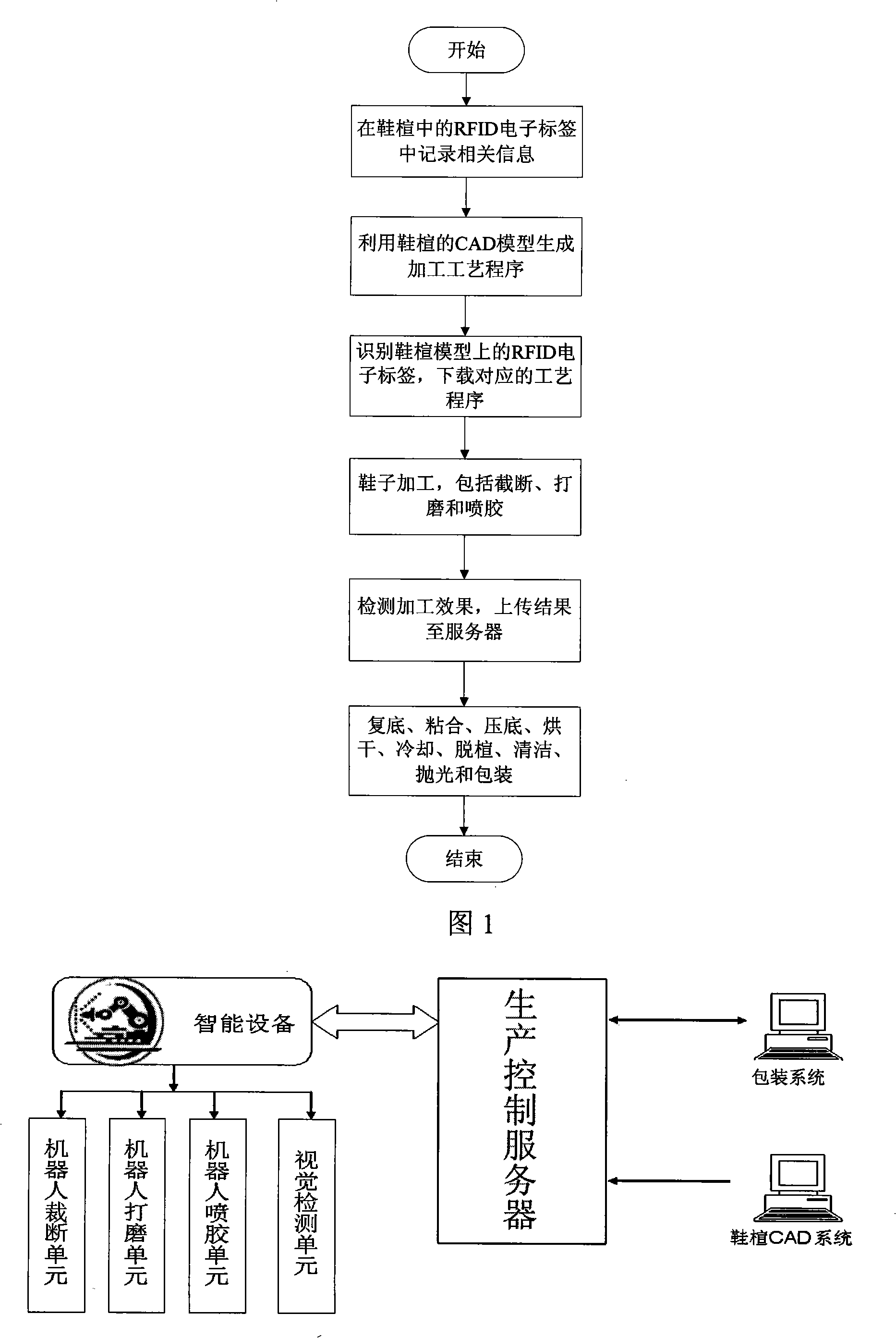

The invention discloses a leather shoe fabrication method driven by information. In the method, an RFID electronic label is embedded in a shoe tree and taken as a sign; furthermore, processing state is recorded; the shoe tree CAD model analysis software is used to extract the required structural geometrical parameters from the shoe tree CAD model; the subsequent processing program is generated; the structural geometrical parameters are then uploaded to a server and shared by various intelligent devices on the production line; when the shoe trees are delivered to various intelligent devices on the production line, after all intelligent devices recognise the RFID electronic labels, the intelligent devices download corresponding processing programs from the server and carry out the processing. The leather shoe fabrication method has the advantages that the processing program is generated by the shoe tree CAD model information, the intelligentization level of the shoe fabrication is improved, the participation of manpower is reduced, and the reliability of the quality is improved.

Description

An information-driven leather shoe manufacturing method technical field The invention relates to the field of computer control, in particular to an information-driven leather shoe manufacturing method. Background technique Leather shoes are articles of daily use in people's lives, and leather shoes manufacture is an important industry in the national economy. Leather shoe making is a traditional craft. At present, the manufacturing process of leather shoes is based on large-scale industrial production. A typical shoe-making process is as follows: First, the worker cuts the leather with a cutting machine, and uses a leather batching machine to batch the leather according to the process requirements; then stitches the batched leather into a shoe upper; then shapes, puts the top and heel into In the lining of the toe and heel, after brushing and sewing, the upper is nailed to the shoe last for overheating and shaping; finally, the upper and the sole are polished and glued...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/418A43D119/00

CPCY02P90/02

Inventor 胡旭东武传宇李秦川史伟民

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com