Glue applying nozzle

A nozzle and glue technology, which is applied in the pretreatment of molding materials, mixers, household components, etc., can solve the problems of large glue consumption, uneven glue application, and easy glue spots, etc., so as to save glue amount and improve product quality Stable and small glue particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0018] Aiming at the shortcomings of the traditional process, we invented two atomizing sizing nozzles, allowing the glue to atomize in the nozzle and enter the fiber spray pipe in the form of mist. The glue can be evenly coated on the surface of the fiber, thereby reducing glue consumption and removing Glue effect.

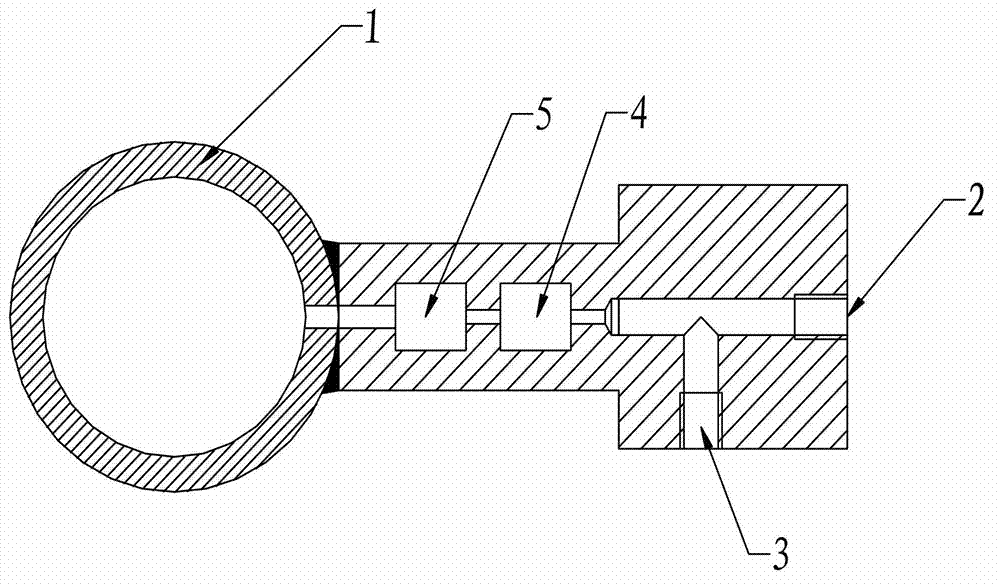

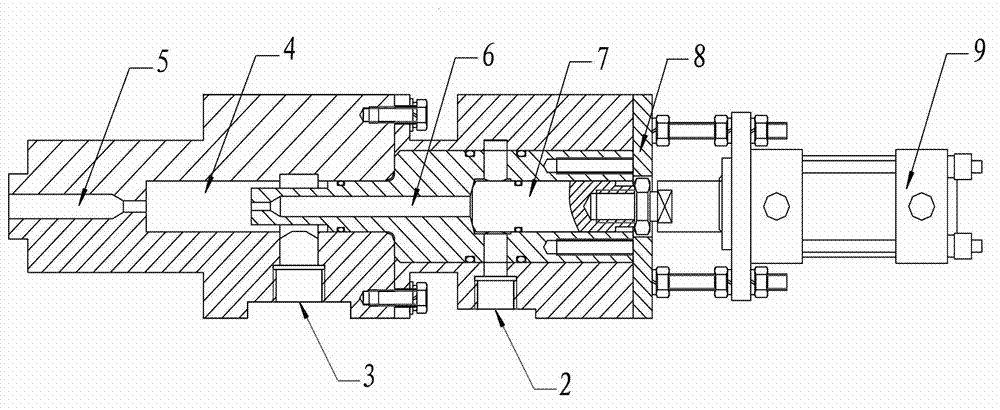

[0019] as attached figure 1 Shown is a schematic diagram of the principle of the two-time atomization sizing nozzle, a sizing nozzle, including a glue inlet 2 and a glue outlet, the glue outlet is connected to the fiber spray pipe 1, and the first section of the pipeline in the sizing nozzle is connected to the glue outlet. The inlet pipe 6 connected to the glue inlet 2, the side wall of the inlet pipe 6 is also connected to the compressed air inlet 3, the diameter of the inlet pipe 6 is smaller than the diameter of the glue inlet 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com