Stone mosaic board and production technology thereof

A production process and technology of mosaic panels, applied in decorative art, covering/lining, construction, etc., can solve the problems of complex floor paving, inability to dry-hang paving, low production efficiency, etc., and achieve production cost reduction and protection Obvious effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

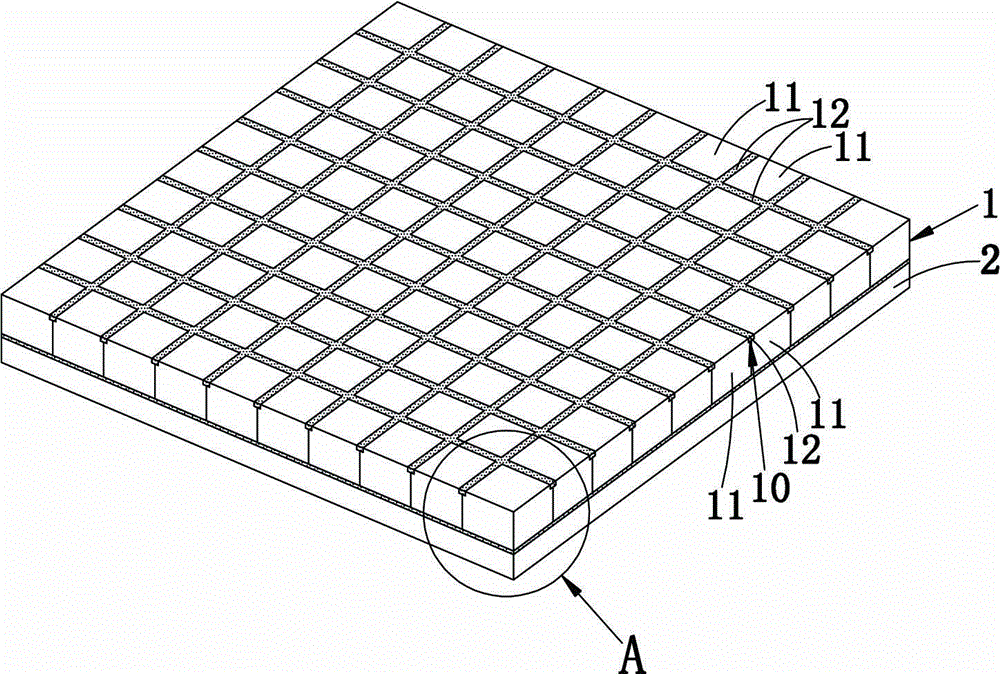

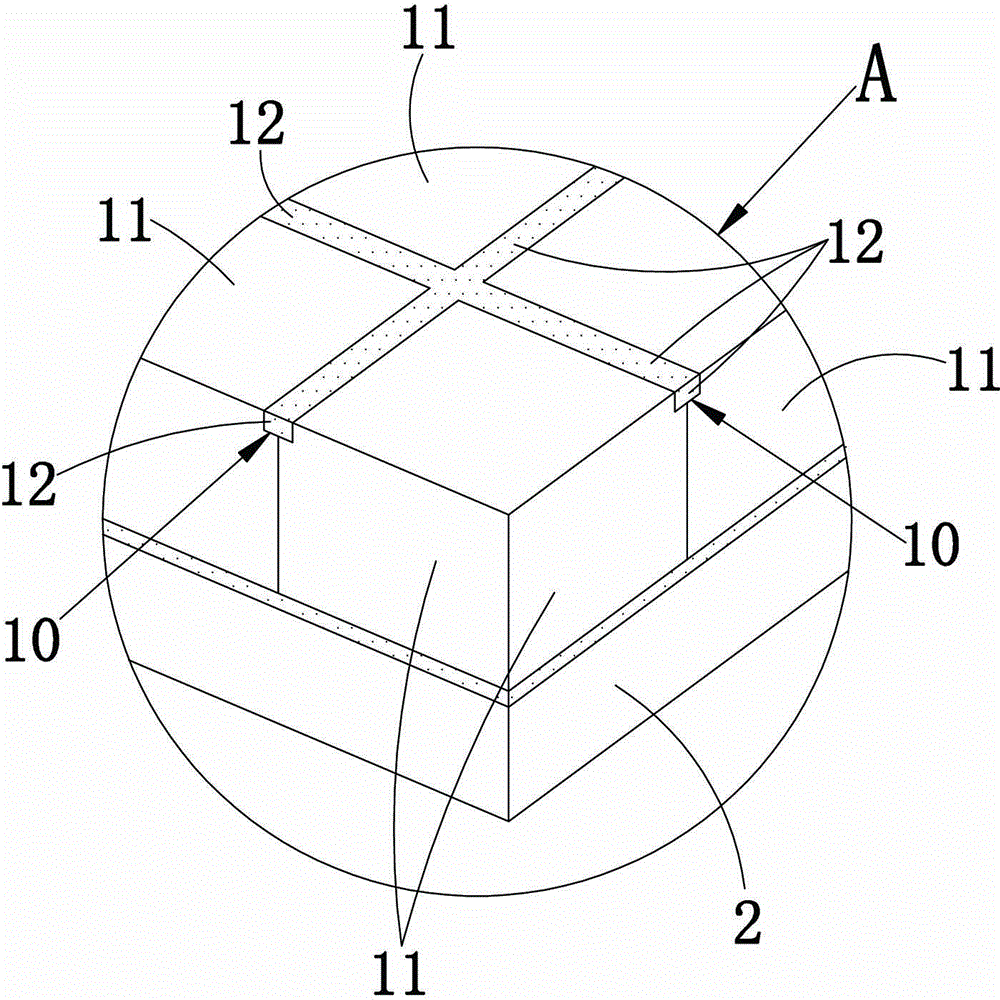

[0030] The stone mosaic composite board includes a main body 1 and a base plate 2 fixedly bonded together, and the main body 1 is formed by splicing a plurality of stones 11 . The stone 11 is preferably a square stone 11 (the stone 11 may also be a rectangle, or even a parallelogram), and the side length of the stone 11 is preferably 10-50 mm. The substrate 2 is one of tiles, marble, aluminum honeycomb, and glass. The upper surface of the main body 1 is provided with criss-cross linear glue grooves 10 . Such as figure 1 , figure 2 As shown, two adjacent stones 11 are seamlessly spliced and the top edge of the spliced surface is provided with the linear glue groove 10 . The width of the linear glue groove 10 is 1-4 millimeters, and the depth of the straight glue groove 10 is 1.5-5 millimeters. The linear glue groove 10 is filled with glue 12 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com