Flame cutting machine nitrogen accompanying purging system and method

A flame cutting machine and nitrogen technology, which is applied in the field of purging system, can solve the problems of scarring at the head and tail of the hot-rolled coil, adverse effects on the life of the roll, etc., and achieve the effect of simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

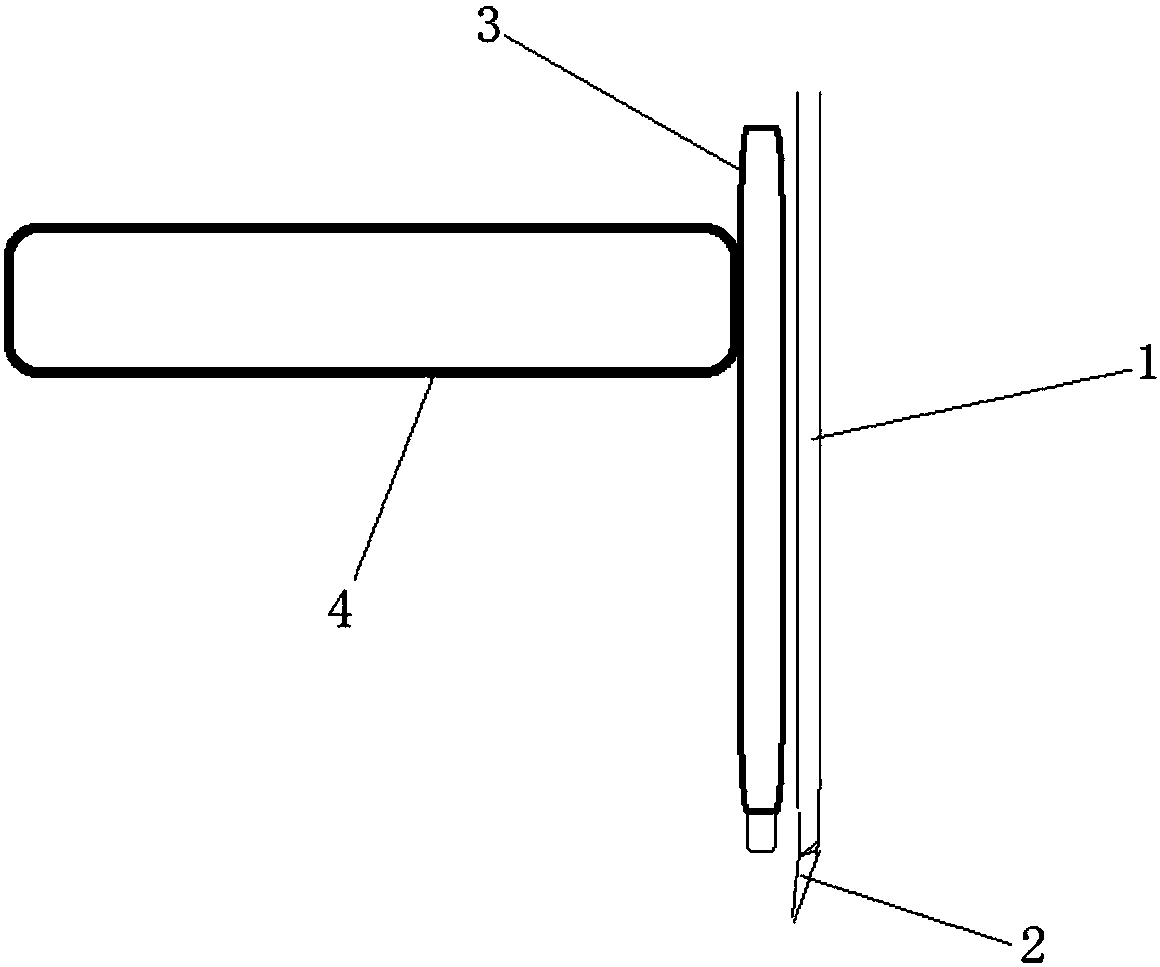

[0019] Such as figure 1 As shown, the nitrogen purging system of the flame cutting machine of the present invention includes: metal hoses, high-pressure nitrogen hard pipes, nozzles and fixtures (comprising ordinary bolts and gaskets), which are connected by metal hoses to connect the high-pressure nitrogen hard pipes according to The casting direction of the slab is fixed at the front / rear position of the torch (main / auxiliary) of the flame cutting machine, and the nozzle at the end of the high-pressure nitrogen hard pipe acts on the oxide position in the molten state on the slab with a specified height, spacing and included angle .

[0020] Nitrogen hard tube adopts The length is 1100-1300mm, the angle between the nozzle and the slab is 75-65°, and the nitrogen pipe network pressure is not less than 10bar.

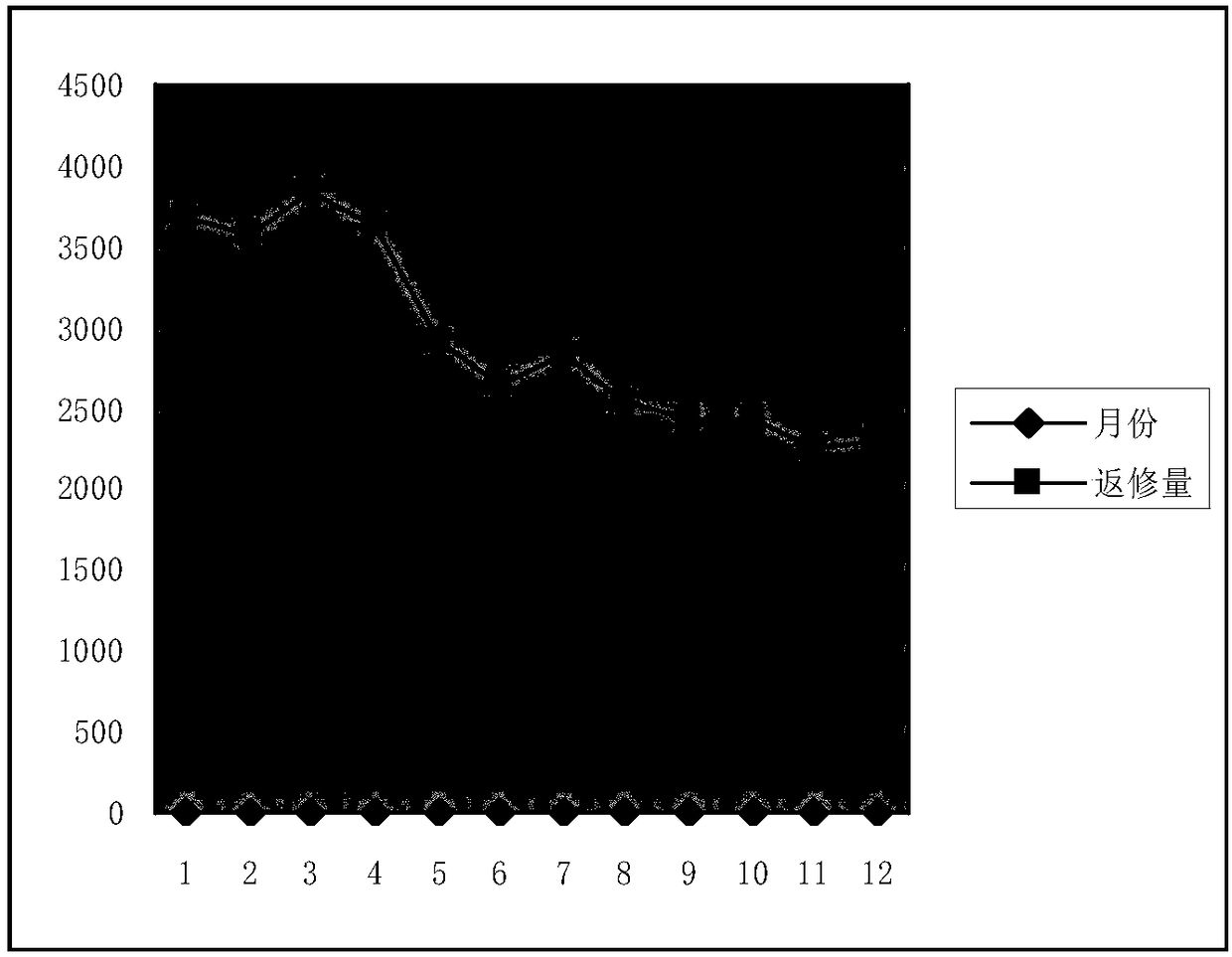

[0021] In this embodiment, the nitrogen source is the existing nitrogen source on site, the pipe network pressure (6bar) can basically meet the use conditions, the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com