Pump head production method

A production method and pump head technology, which are applied in the components of pumping devices for elastic fluids, pump components, variable displacement pump components, etc., can solve the problems of rough product surface, large resource consumption and high product cost, and achieve The effect of good roughness, low labor intensity and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

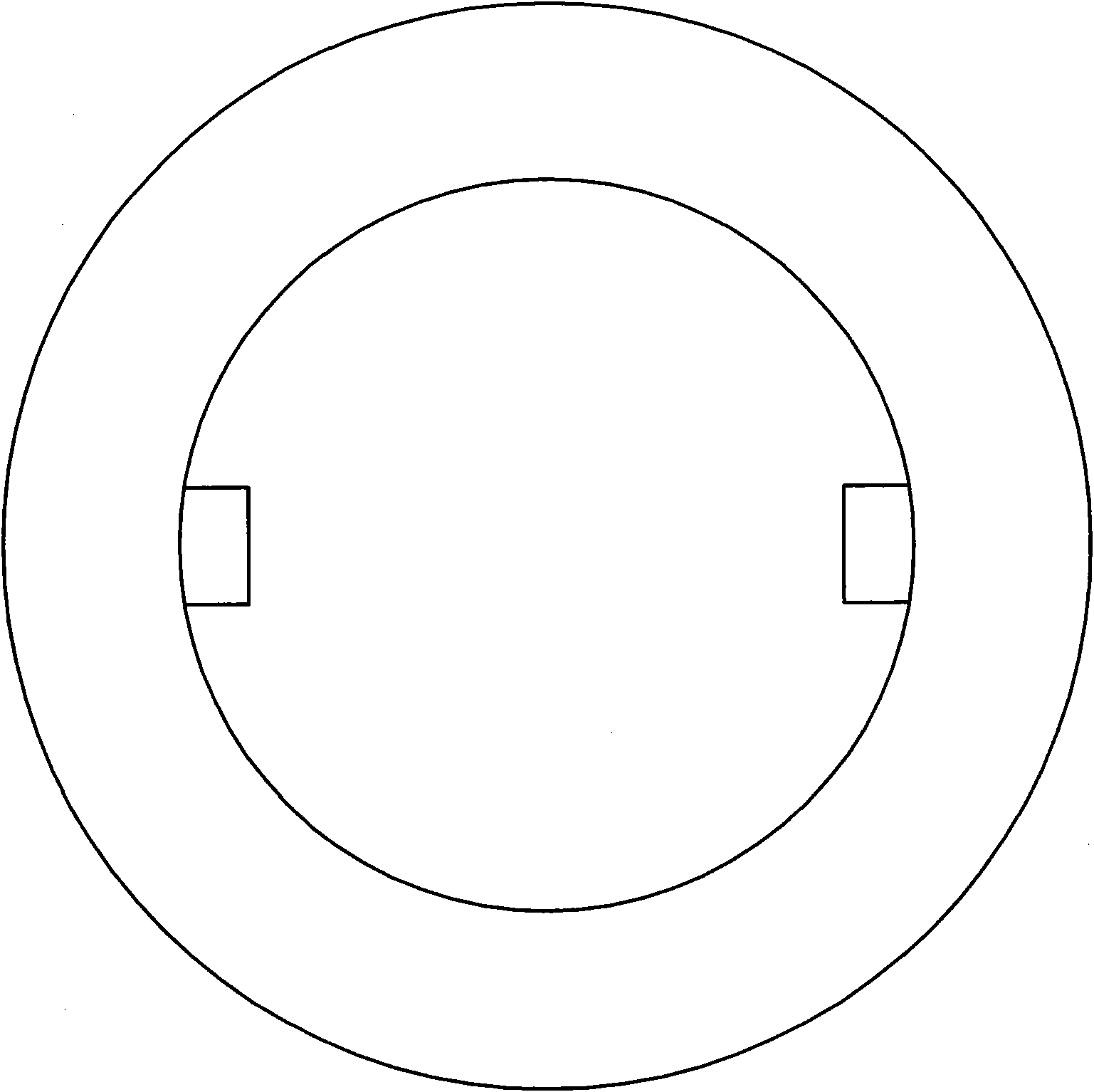

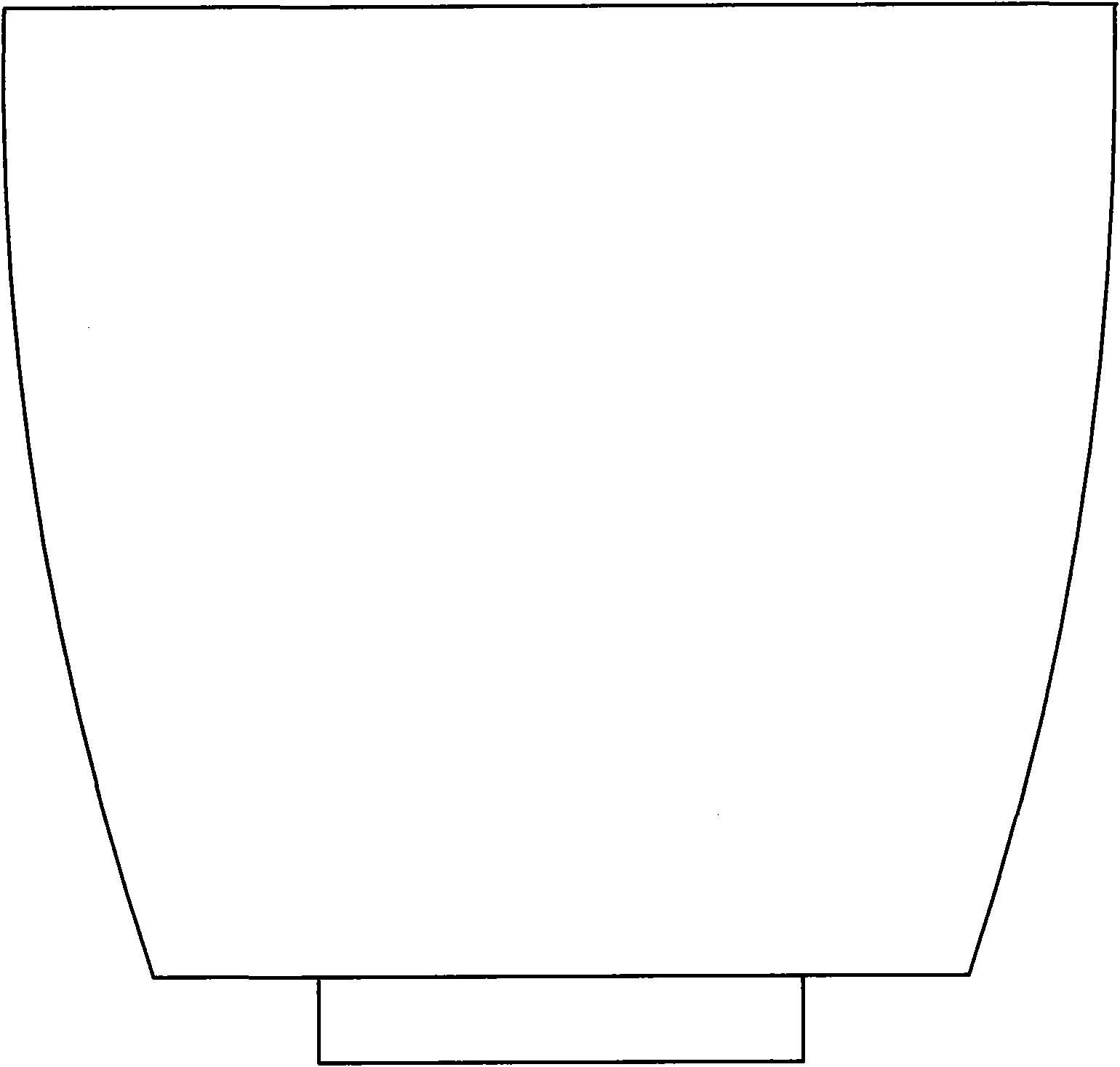

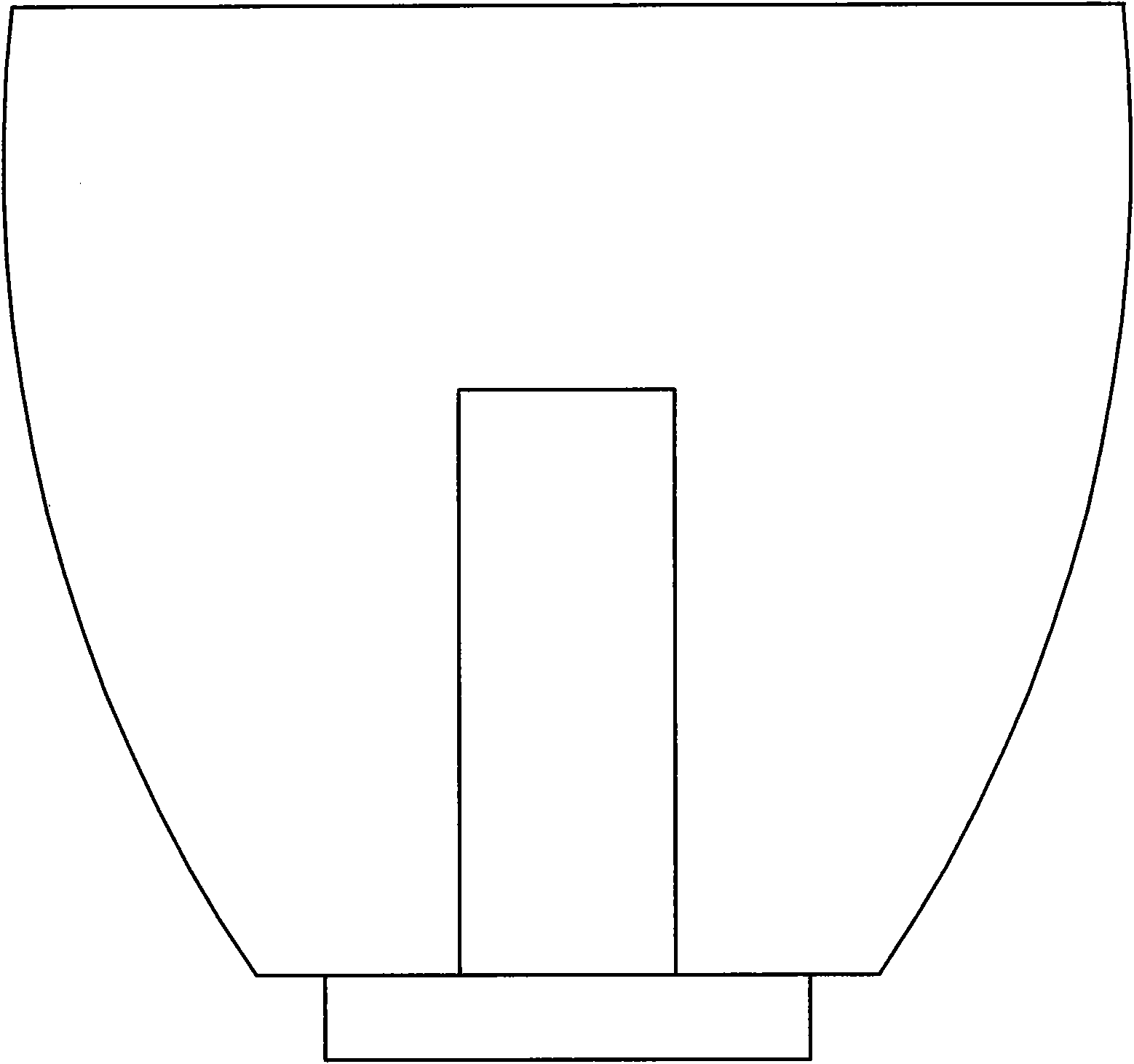

Image

Examples

Embodiment 1

[0031] A production method of a pump head, which sequentially comprises the following production steps:

[0032] (1) After adding the iron-containing raw materials into the intermediate frequency electric furnace, the iron-containing raw materials are heated to melt the iron-containing raw materials into molten iron. The iron-containing raw materials include pig iron, scrap steel, recycled materials, and ferrosilicon and ferromanganese, pig iron is an iron-carbon alloy with a carbon content between 2% and 4.3%, scrap steel is a variety of steel products recycled, and returned materials are defective products and waste products produced. Ferrosilicon and ferromanganese are respectively silicon-containing Iron alloy with manganese to adjust the content of silicon and manganese in the product;

[0033] (2) Put the spheroidizing agent and alloy raw materials into the ladle, the nodulizing agent is ReMg3-8, the alloy raw materials are copper and magnesium, and magnesium also has sp...

Embodiment 2

[0040] A production method of a pump head, which sequentially comprises the following production steps:

[0041] (1) After adding the iron-containing raw materials into the intermediate frequency electric furnace, the iron-containing raw materials are heated to melt the iron-containing raw materials into molten iron. The iron-containing raw materials include pig iron, scrap steel, recycled materials, and ferrosilicon and ferromanganese, pig iron is an iron-carbon alloy with a carbon content between 2% and 4.3%, scrap steel is a variety of steel products recycled, and returned materials are defective products and waste products produced. Ferrosilicon and ferromanganese are respectively silicon-containing Iron alloy with manganese to adjust the content of silicon and manganese in the product;

[0042] (2) Put the spheroidizing agent and alloy raw materials into the ladle, the nodulizing agent is ReMg3-8, the alloy raw materials are copper and magnesium, and magnesium also has sp...

Embodiment 3

[0049] A production method of a pump head, which sequentially comprises the following production steps:

[0050] (1) After adding the iron-containing raw materials into the intermediate frequency electric furnace, the iron-containing raw materials are heated to melt the iron-containing raw materials into molten iron. The iron-containing raw materials include pig iron, scrap steel, recycled materials, and ferrosilicon and ferromanganese, pig iron is an iron-carbon alloy with a carbon content between 2% and 4.3%, scrap steel is a variety of steel products recycled, and returned materials are defective products and waste products produced. Ferrosilicon and ferromanganese are respectively silicon-containing Iron alloy with manganese to adjust the content of silicon and manganese in the product;

[0051] (2) Put the spheroidizing agent and alloy raw materials into the ladle, the nodulizing agent is ReMg3-8, the alloy raw materials are copper and magnesium, and magnesium also has sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com