Small hole punching mechanism

A punching and punching technology, which is applied in the field of small hole punching mechanism, can solve the problems of high frequency of punch replacement, secondary positioning error, and increase of processing cost, and achieve short replacement time, long service life and save processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

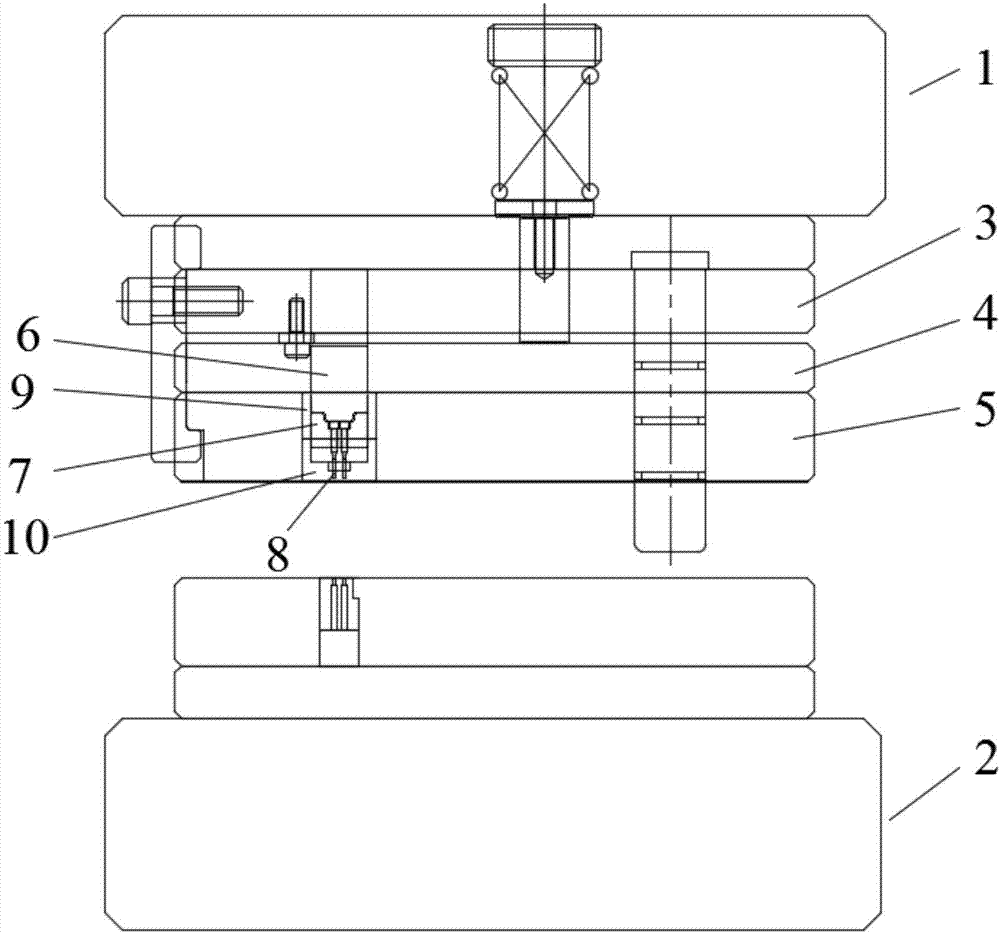

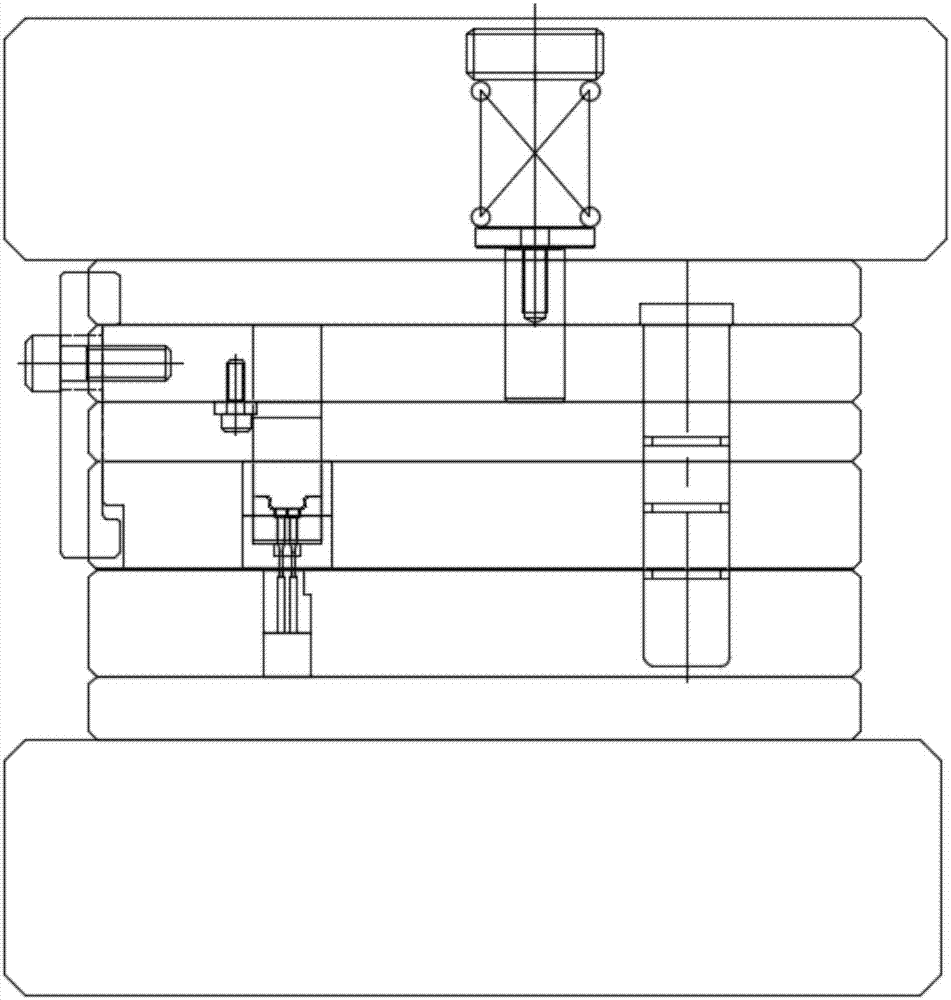

[0013] Such as figure 1 and figure 2 As shown, the present embodiment provides a small hole punching mechanism, which includes an upper die 1 and a lower die 2; the upper die 1 includes an upper clamping plate 3, a stopper plate 4, a stripping plate 5 and a punching device; The blanking device comprises a first punch clamping block 6, a second punch clamping block 7, a punch 8, a first off-board entry 9 and a second off-board entry 10; the first punch The clamping block 6 is connected with the second punch clamping block 7 through the dovetail groove slide table; the punch 8 is passed through the second punch clamp block 7, and the tail of the punch 8 is stuck in the dovetail groove slide table. Bottom; the first punch clamping block 6 and the second punch clamping block 7 are jointly installed in the upper clamping plate 3, the stopper plate 4 and the stripping plate 5, and the second stripping plate entry 10 is set On the underside of the first stripping insert 9; the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com