Technique for eliminating magnetic blow of electric arc of austenitic electrode by using permanent magnet

A permanent magnet, electrode arc technology, applied in the characteristics of welding electrodes, arc welding equipment, electrode accessories, etc., can solve the problems of inability to eliminate magnetic bias blowing, unable to guarantee welding construction, etc., to solve the problem of magnetic bias blowing and ensure the quality of welding. , the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

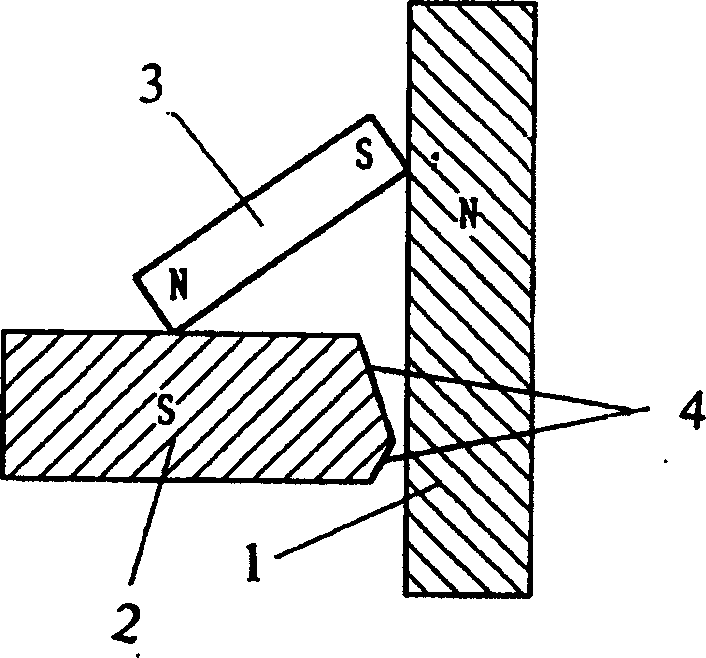

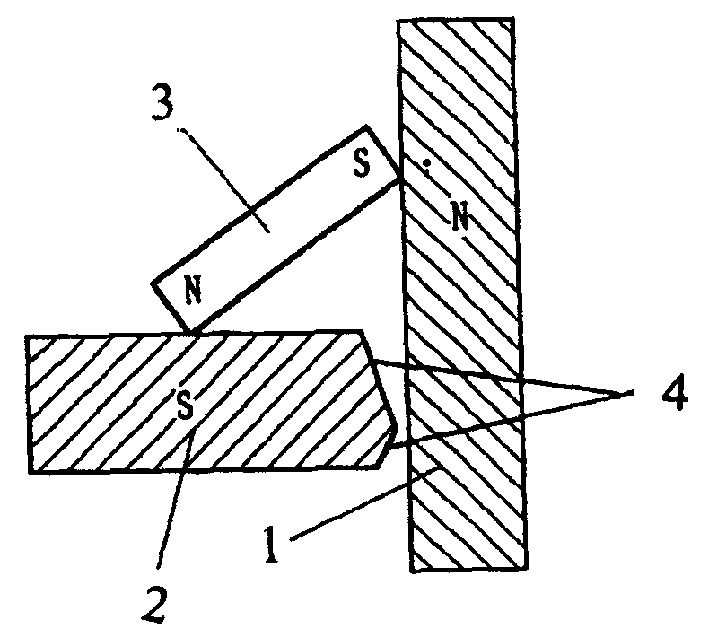

[0011] A method for eliminating the magnetic deflection of an austenitic electrode arc with a permanent magnet. First, a Tesla meter with a range of 0-1000mT and a reading of one decimal place is selected, and a permanent magnet 3 of NdFeB material with a large magnetic induction intensity is selected. Its length should not be less than 80mm, and the magnetic induction intensity can be 1000mT, 2000mT, 5000mT and other specifications. Then measure the magnetic induction intensity and the orientation of the magnetic poles at the groove 4 on the welding workpiece 2 with a Teslameter, select one or more permanent magnets 3 of the above-mentioned magnetic induction intensity specifications to be adsorbed on the groove top, and the N pole of the permanent magnet 3 is attracted. At the S pole of the workpiece 2, the S pole of the permanent magnet 3 is attracted to the N pole of the workpiece 1, so that the magnetic induction intensity of the permanent magnet 3 is equivalent to the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com