Aluminum electrolysis anode guide rod automatic repair method and production line

An aluminum electrolytic anode and automatic repair technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., to optimize the repair process, reduce the use of pressure, and improve the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

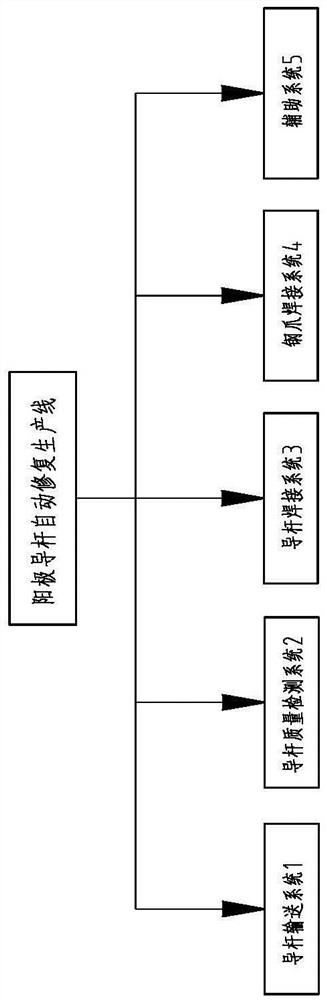

[0026] Such as figure 1 As shown, it is an automatic repair production line for aluminum electrolytic anode guide rods, including aluminum rod welding system 3 and steel claw welding system 4, and also includes: guide rod quality inspection system 2, which is used for surface damage analysis and / or analysis of anode guide rods Or internal flaw detection; guide rod conveying system 1, transfers the anode guide rod to the aluminum rod welding system 3 and / or steel claw welding system 4 according to the information of the guide rod quality inspection system 2, and transfers the anode guide rod within the scope of the production line; The auxiliary system 5 provides material support, temperature control and dust recovery for the aluminum rod welding system 3 and the steel claw welding system 4 .

[0027] Compared with the prior art in which the aluminum rod welding system 3 and the steel claw welding system 4 are operated in sequence, this embodiment can carry out refined detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com