Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

A control method and hot-rolled coil technology, applied in the field of hot-rolled side guide plate control, can solve problems such as defects, edge gap quality, and edge out, and achieve the effect of reducing production costs and reducing the amount of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

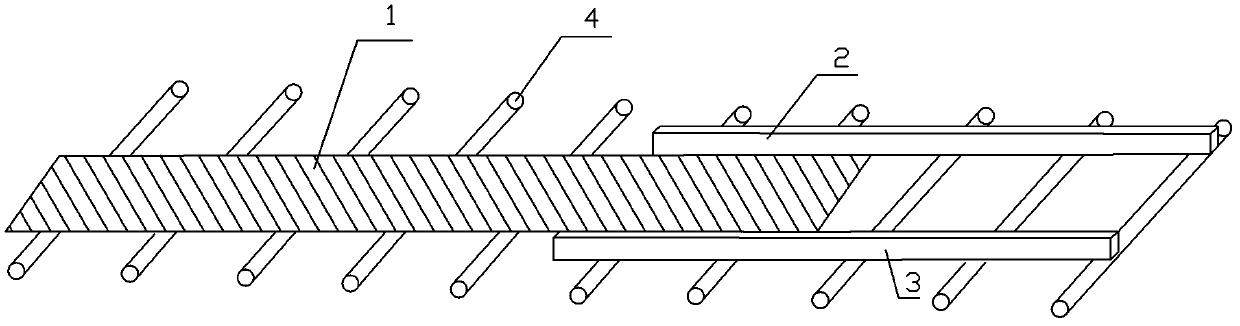

Image

Examples

Embodiment 1

[0030] This embodiment is a method for controlling hot-rolled coiling side guides to improve the quality of hot-rolled coils, rolling a strip with a thickness of 2.2 mm, a width of 1032 mm, and a set pressure of the side guides at 0.6 ton.

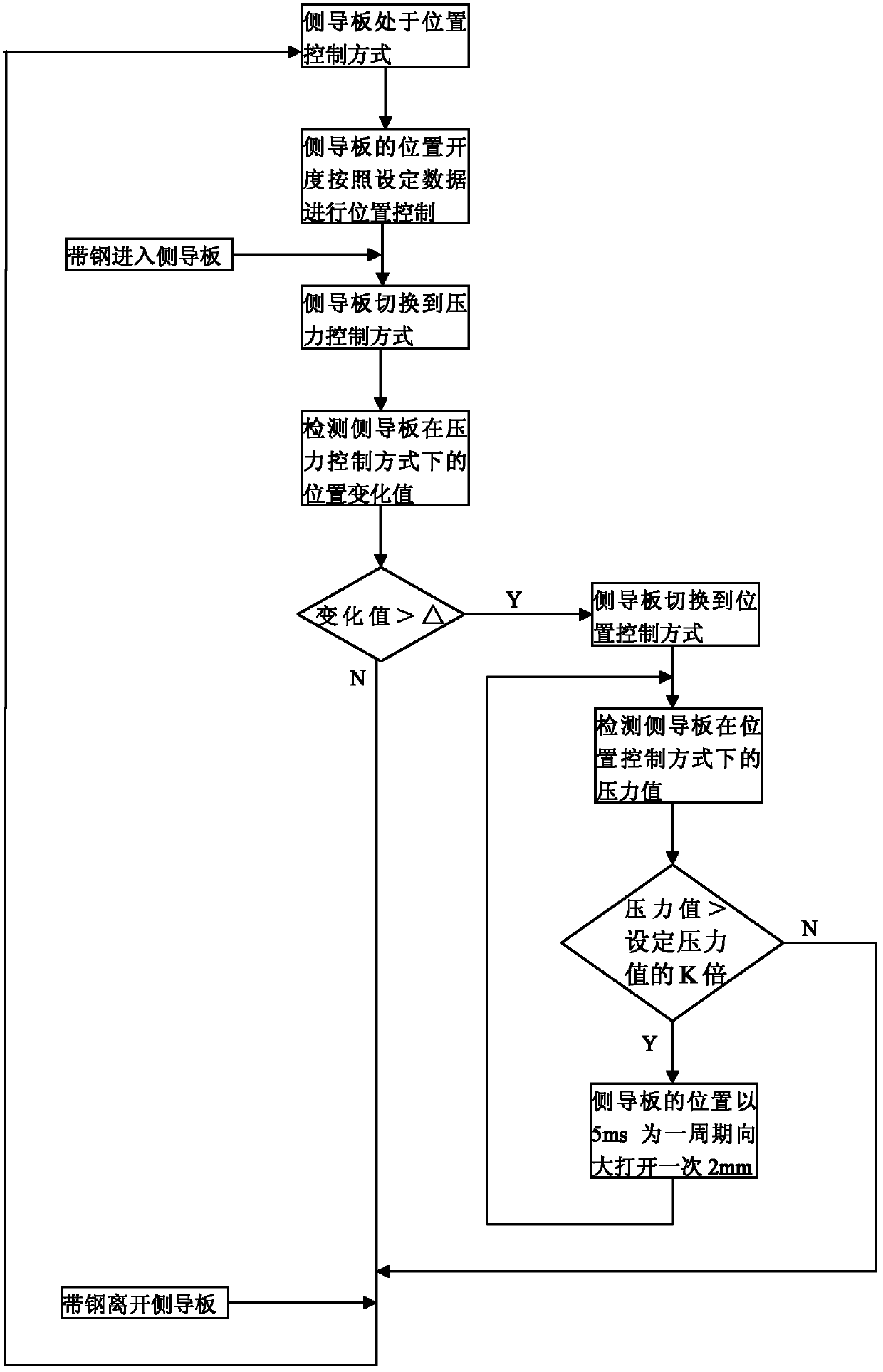

[0031] Switching the side guide plate from the pressure control mode to the position control mode depends on the position change value of the side guide plate under the pressure control mode. Only when the change value is greater than △X can the switch be made, and the value of △X is set according to the thickness of the strip. The specific parameters are: when H4.5 mm, △X=5mm; H is the strip thickness.

[0032] After the side guide plate is switched from the pressure control mode to the position control mode, the position of the side guide plate is opened to the maximum depending on the pressure value of the side guide plate in the position control mode. Only when the pressure value is greater than K times the pressure setting value is it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com