Fabrication method of copper crafts

A production method and technology of handicrafts, applied in the direction of machine tools suitable for grinding the edge of workpieces, techniques for producing decorative surface effects, decorative arts, etc., which can solve the problems of large amount of repair, long price and production cycle, improper production process, etc. problems, achieve the effect of reducing the amount of repairs and scrap rate, improving the quality of handicrafts, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

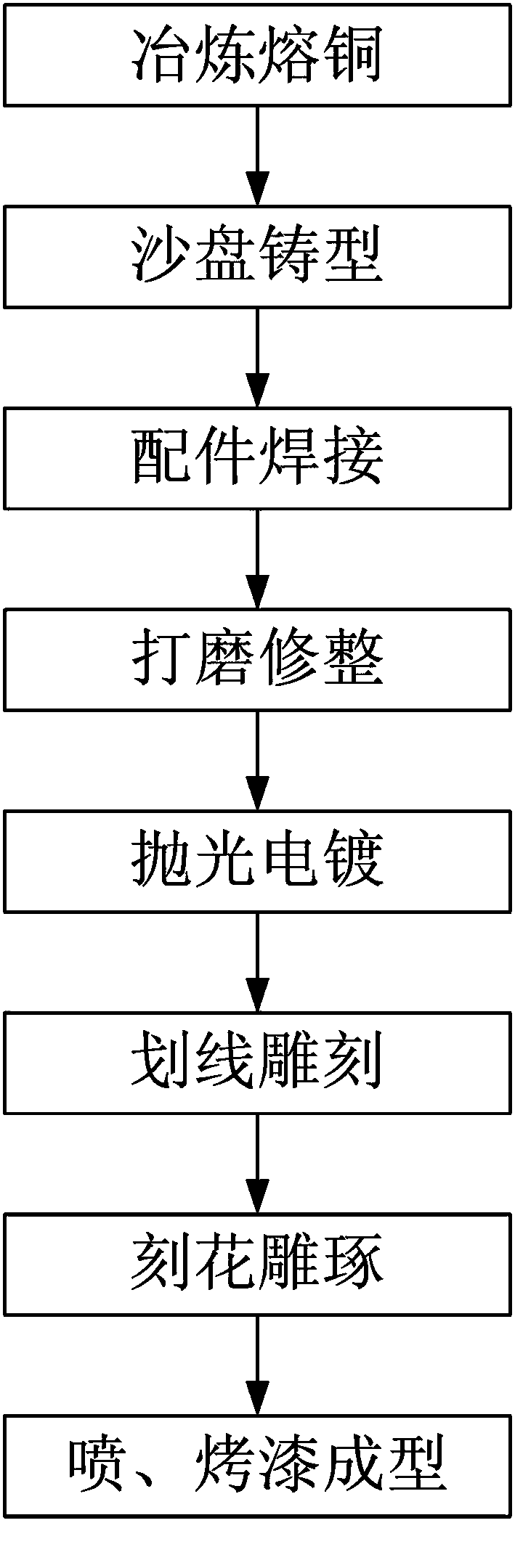

[0023] A kind of manufacturing method of copper handicraft described in the embodiment of the present invention, such as figure 1 shown, including the following steps:

[0024] (1) Smelting and melting copper: put 1.5kg of copper, 0.2kg of tin, 0.24kg of lead and 0.06kg of aluminum in a smelting ladle, then place the smelting ladle on a charcoal stove for melting, when the temperature reaches 1083°C When left or right, the copper ingot is melted into copper water to prepare a copper-water mixture for casting; the abrasive mold cast at this ratio is soft and hard, suitable for carving, and the copper thorns are easy to fall off.

[0025] (2) Sand table casting: according to the shape of the parts to be cast, select an appropriate sand table filled with fine sand, press out the shape of the casting parts on the sand table, and paint the surface with paraffin, so that the abrasive will not produce product bubbles , seal the sand table, pour the copper-water mixture into the sand...

Embodiment 2

[0035] The embodiment of this embodiment is basically the same as that of Embodiment 1, the difference is that when smelting molten copper in Step 1, 1.44 kg of copper, 0.16 kg of tin, 0.2 kg of lead, and 0.02 kg of aluminum are added to the smelting spoon. kg.

Embodiment 3

[0037] The embodiment of this embodiment is basically the same as that of Embodiment 1, the difference is that when smelting molten copper in Step 1, 1.56 kg of copper, 0.24 kg of tin, 0.28 kg of lead, and 0.1 kg of aluminum are added to the smelting spoon. kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com