Terminal crack prevention process of Q420 high-strength steel flux copper backing submerged-arc welding

A high-strength steel and copper liner technology, applied in arc welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of inability to penetrate, increase welding workload, etc., to prevent the generation of terminal cracks, The effect of reducing the occurrence rate of terminal cracks and increasing the crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

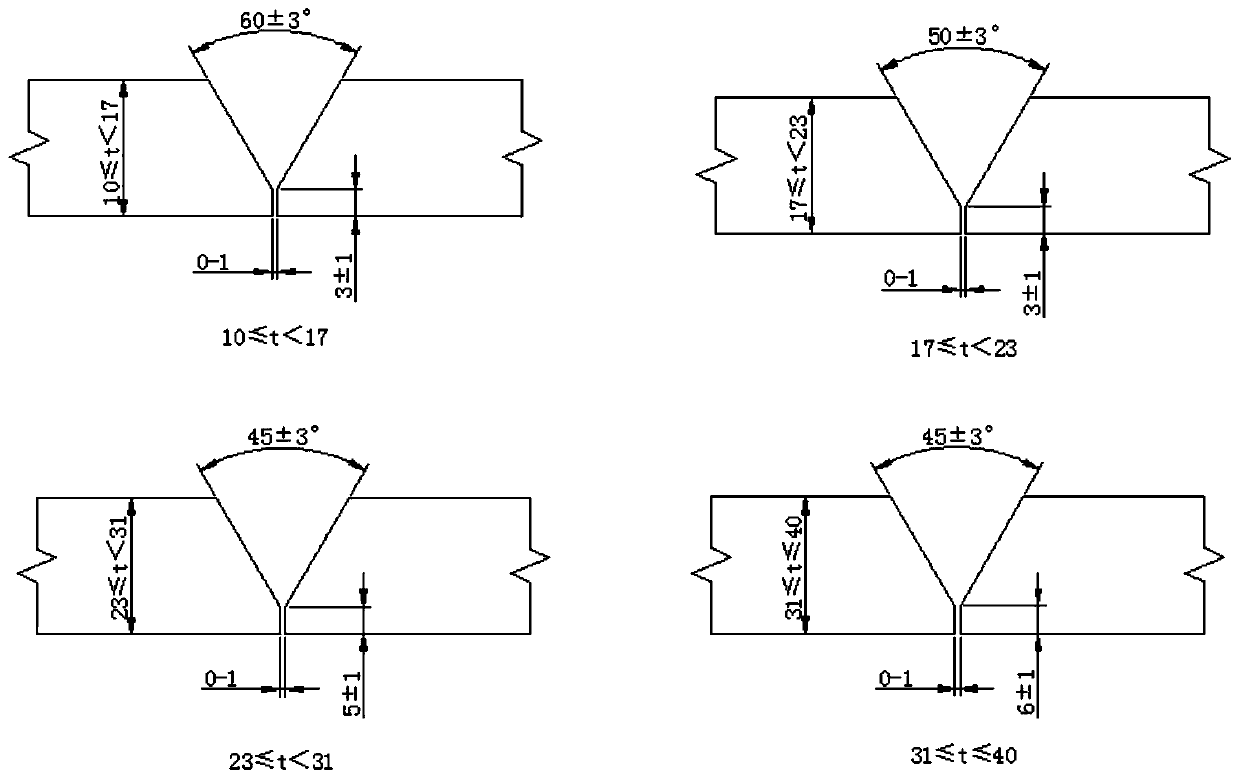

[0032] This embodiment discloses a terminal crack prevention process of Q420 high-strength steel flux-copper-lined submerged arc welding, which is mainly applied to Q420 high-strength steel with a thickness of 10mm≤t<17mm, including the following steps:

[0033] Step 1, process the Y-shaped welding groove at the welding place of the steel plate, see for details figure 1 , where the opening angle of the Y-shaped welding groove is 57°-63°, the blunt edge is 2-4mm, and the root gap is 0-1mm; after the Y-shaped welding groove is processed, the Y-shaped welding groove surface and the Y-shaped welding Clean up the oxide layer and impurities within 20mm around the groove;

[0034] In the present invention, the setting of the groove parameters is mainly related to the welding heat input and the welding seam forming effect. According to the plate thickness in this embodiment, the groove parameters are correctly matched, and the welding heat input and the welding seam forming effect ar...

Embodiment 2

[0057] This embodiment discloses a terminal crack prevention process of Q420 high-strength steel flux-copper-lined submerged arc welding, which is mainly applied to Q420 high-strength steel with a thickness of 17mm≤t<23mm, and specifically includes the following steps:

[0058] Step 1, step 1, process Y-shaped welding grooves at the welding place of the steel plate, see for details figure 1 , where the opening angle of the Y-shaped welding groove is 47°-53°, the blunt edge is 2-4mm, and the root gap is 0-1mm; after the Y-shaped welding groove is processed, the Y-shaped welding groove surface and the Y-shaped welding Clean up the oxide layer and impurities within 20mm around the groove;

[0059] Steps 2 to 8 are the same as those in Embodiment 1, and will not be repeated here.

[0060] Among them, the relationship between the design idea of the opening angle, the size of the blunt edge and the thickness of the Q420 high-strength steel, please refer to the description in Embo...

Embodiment 3

[0062] This embodiment discloses a terminal crack prevention process of Q420 high-strength steel flux-copper-lined submerged arc welding, which is mainly applied to Q420 high-strength steel with a thickness of 23mm≤t<31mm, and specifically includes the following steps:

[0063] Step 1, step 1, process Y-shaped welding grooves at the welding place of the steel plate, see for details figure 1 , where the opening angle of the Y-shaped welding groove is 42°-48°, the blunt edge is 4-6mm, and the root gap is 0-1mm; after the Y-shaped welding groove is processed, the Y-shaped welding groove surface and the Y-shaped welding Clean up the oxide layer and impurities within 20mm around the groove;

[0064] Steps 2 to 8 are the same as those in Embodiment 1, and will not be repeated here.

[0065] Among them, the relationship between the design idea of the opening angle, the size of the blunt edge and the thickness of the Q420 high-strength steel, please refer to the description in Embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com