Thermal treatment and deformation prevention tool for thin-wall cylinder body casting and thermal treatment charging method thereof

An anti-deformation and cylinder technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as deformation of cylinder castings and concave deformation in the cylinder, so as to prevent concave deformation, reduce the workload of shaping, and prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

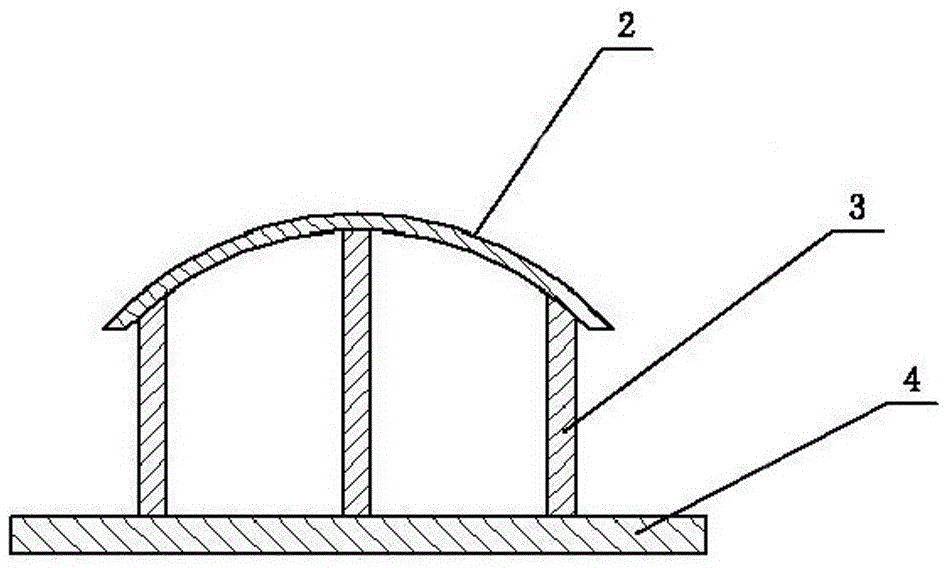

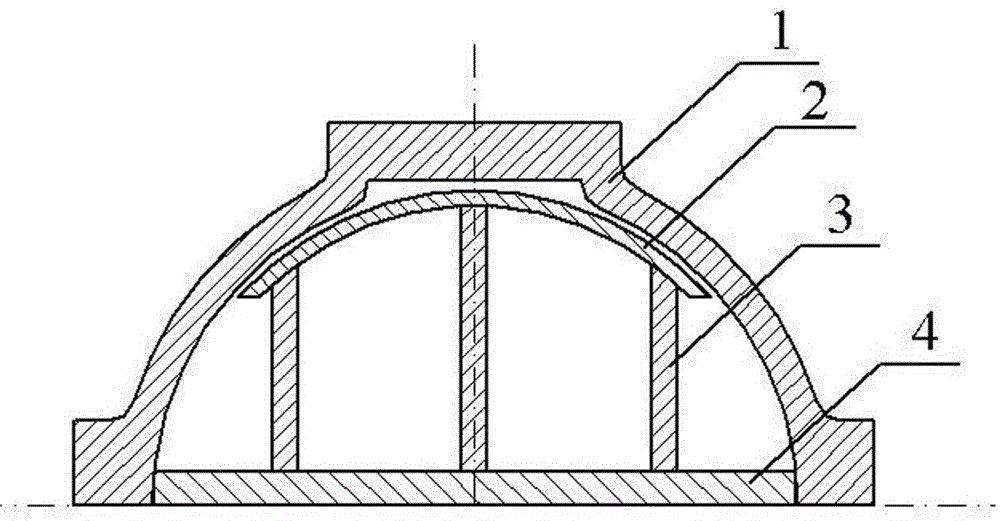

[0013] Such as figure 1 and figure 2 Shown is the anti-deformation tooling for heat treatment of thin-walled cylinder castings according to the present invention, which includes a number of supporting parts arranged at intervals along the axial inner side of the casting of the cylinder 1, and the supporting parts include an arc-shaped support body 2 for supporting the inner wall of the cylinder 1 , the arc of the arc-shaped support body 2 is 60°-90°, the outer arc surface of the arc-shaped support body 2 has the same radius as the arc surface of the inner wall of the cylinder, and a number of support rods 3 are vertically arranged on the arc-shaped inner side of the arc-shaped support body 2, The lower end of the support rod 3 is fixedly supported on the support plate 4 arranged horizontally. The width of the support plate 4 along the axial direction of the cylinder body is the same as the width of the arc support body 2 or slightly larger than the width of the arc support bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com