Rear floor longitudinal beam forming mold

A technology for forming molds and rear floors, applied in forming tools, manufacturing tools, metal processing, etc., can solve the problems of low machining accuracy of forming molds and complicated steps, and achieve the effect of preventing left and right deviation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the technical content of the present invention is further described:

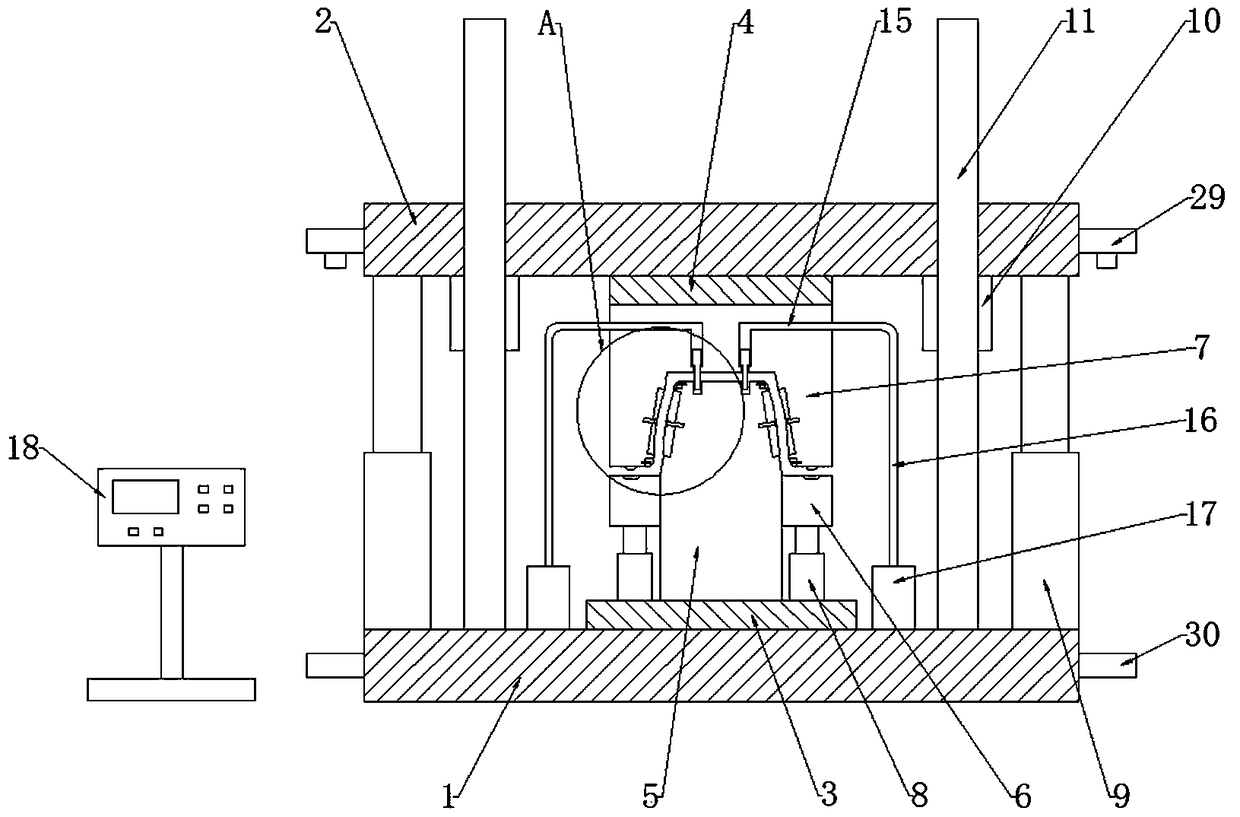

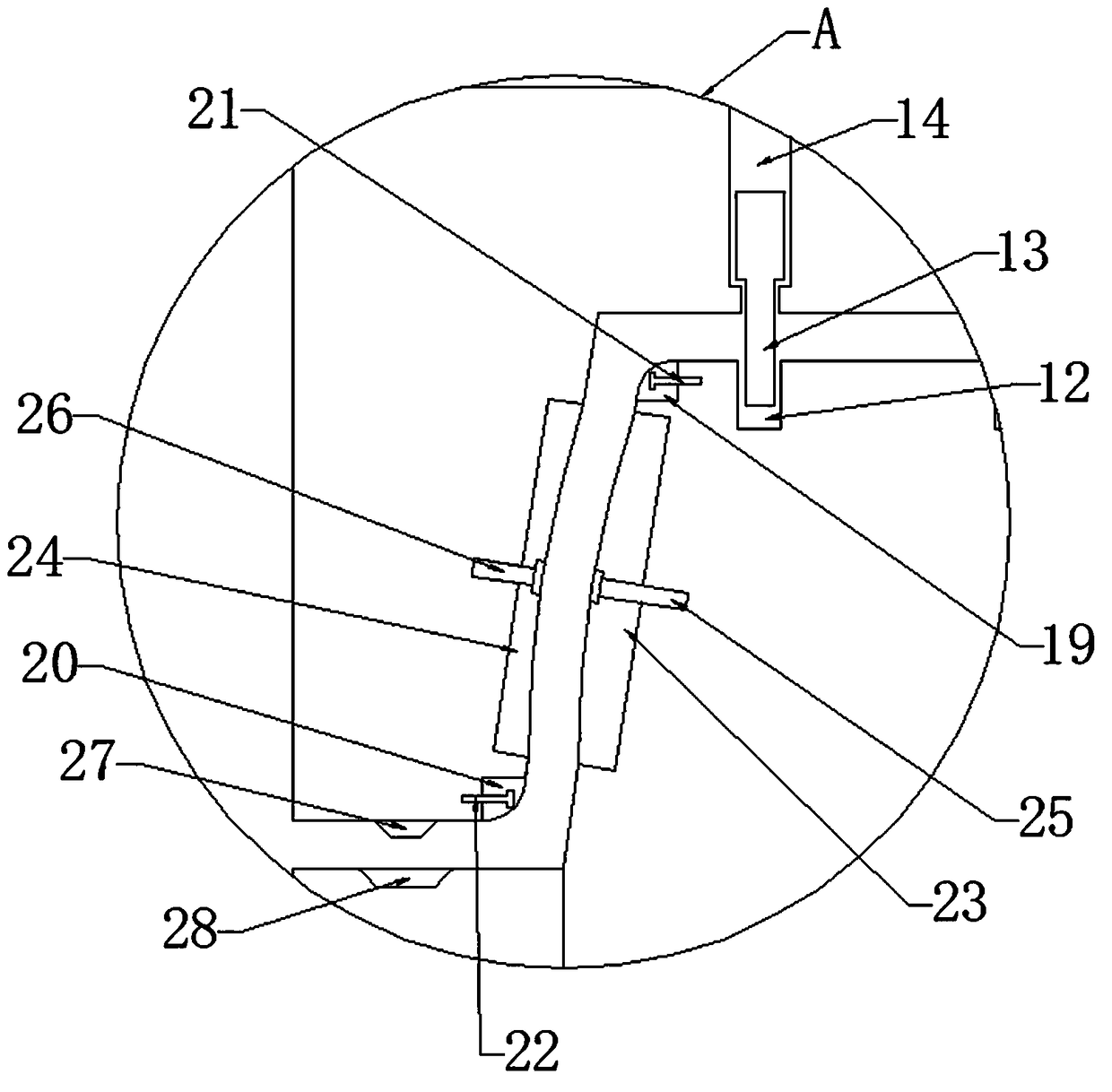

[0020] Figure 1~2 A rear floor stringer forming mold of the present invention is shown, comprising:

[0021] Lower mold base 1, upper mold base 2, lower backing plate 3, upper backing plate 4, lower punch 5, N lower movable mold 6, upper die 7, N hydraulic telescopic cylinders-8, P hydraulic telescopic cylinders 9. Q guide sleeves 10, Q guide posts 11, R punch holes 12, R punches 13, R hydraulic cylinders 14, R hydraulic inner tubes 15, R hydraulic outer tubes 16, R hydraulic pressure Pump 17, control box 18;

[0022] The lower backing plate 3 is arranged on the lower backing plate 1, the upper backing plate 4 is arranged on the upper backing plate 2, the lower punch 5 is arranged on the lower backing plate 3, and N hydraulic telescopic cylinders-8 are arranged on the lower backing plate 3, N lower movable molds 6 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com