Welding repair method for local defect of crankshaft for ship

A local defect, welding repair technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high requirements on equipment and product surface conditions, unfavorable economic benefits, and difficult operation, and achieve high operating efficiency, The effect of strong operability and reduction of repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

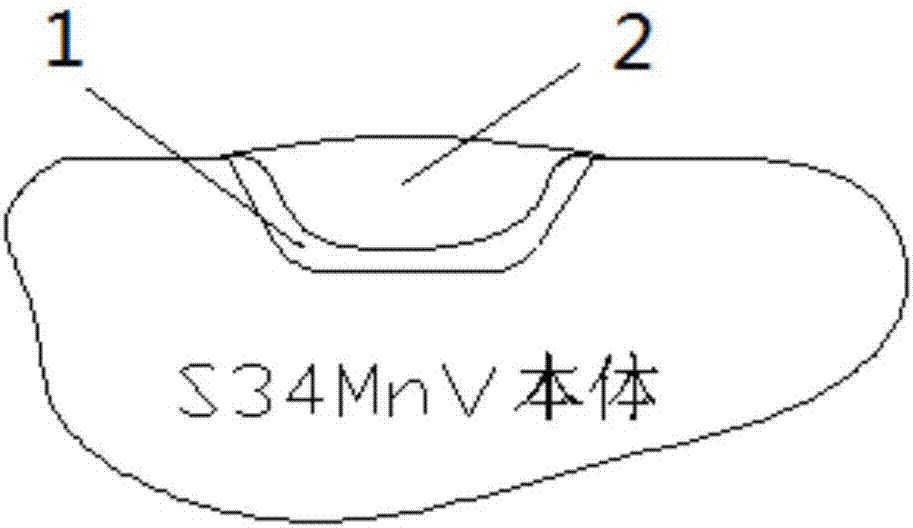

[0013] The automatic welding process of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

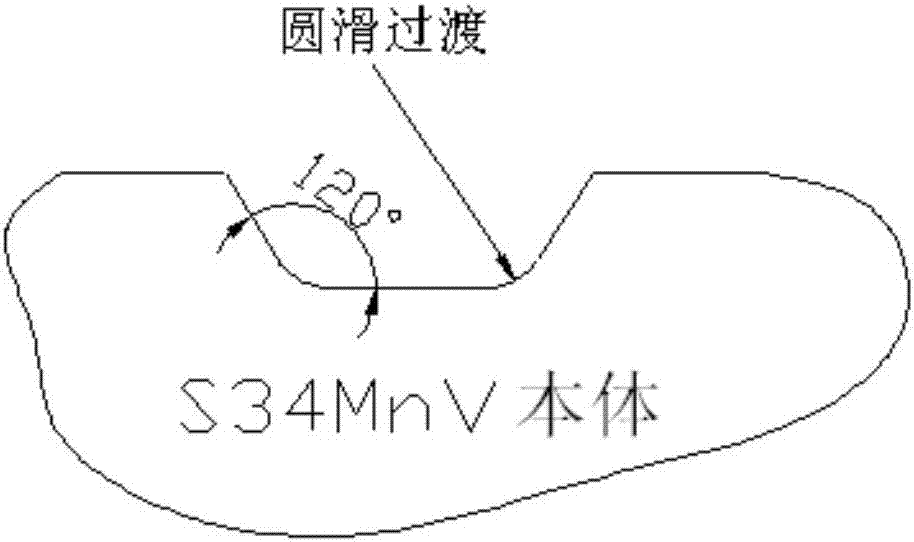

[0014] The invention provides a welding repair method for local defects of a crankshaft made of S34MnV material, which can be applied to the repair of local defects of the crankshaft of a marine diesel engine. The cold welding method is used for welding, which avoids the problem of preheating before welding, and has high efficiency and simple operation. , The process is easy to realize and so on.

[0015] The material of the marine crankshaft involved in the present invention is S34MnV, and its chemical composition is shown in Table 1:

[0016] Table 1 S34MnV chemical composition

[0017] C%

Si%

Mn%

P%

S%

Cr%

V%

0.34

0.25

1.2

0.01

0.005

0.05

0.1

[0018] Its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com